Pore plate grating system

An orifice plate and grid technology, which is applied in the field of sewage treatment, can solve the problems of reducing the interception accuracy, and achieve the effect of improving the removal rate, improving the effect of sewage treatment and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

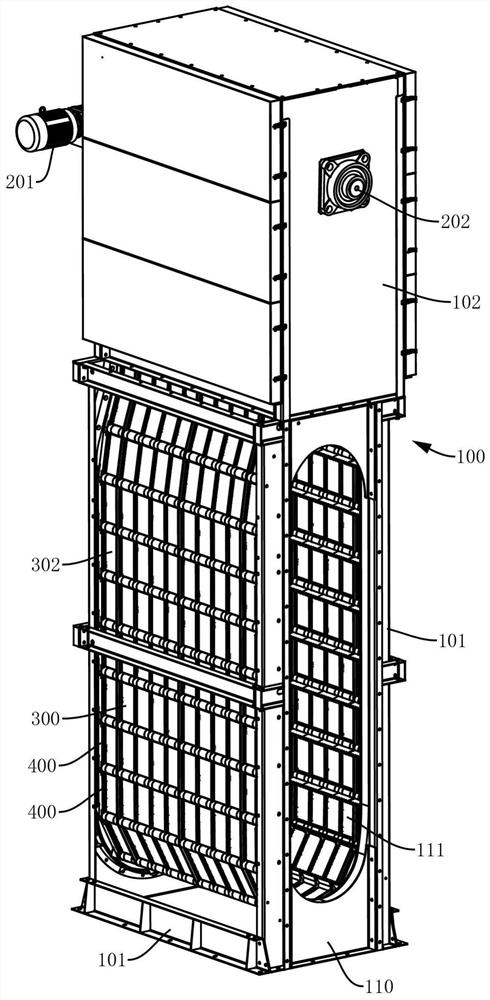

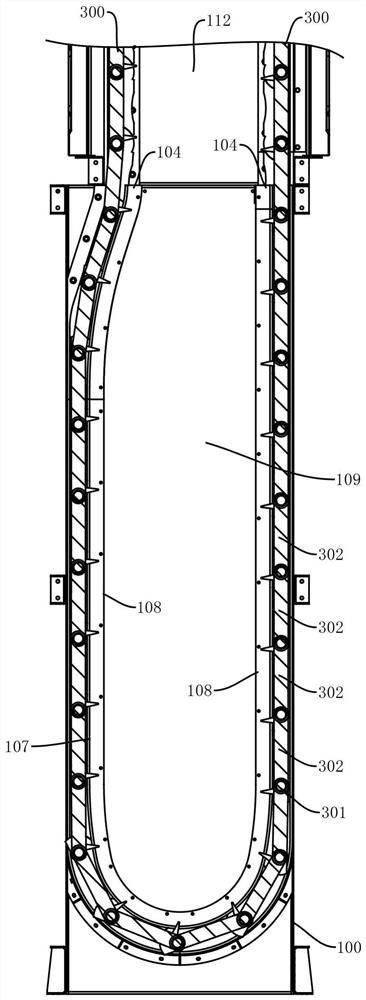

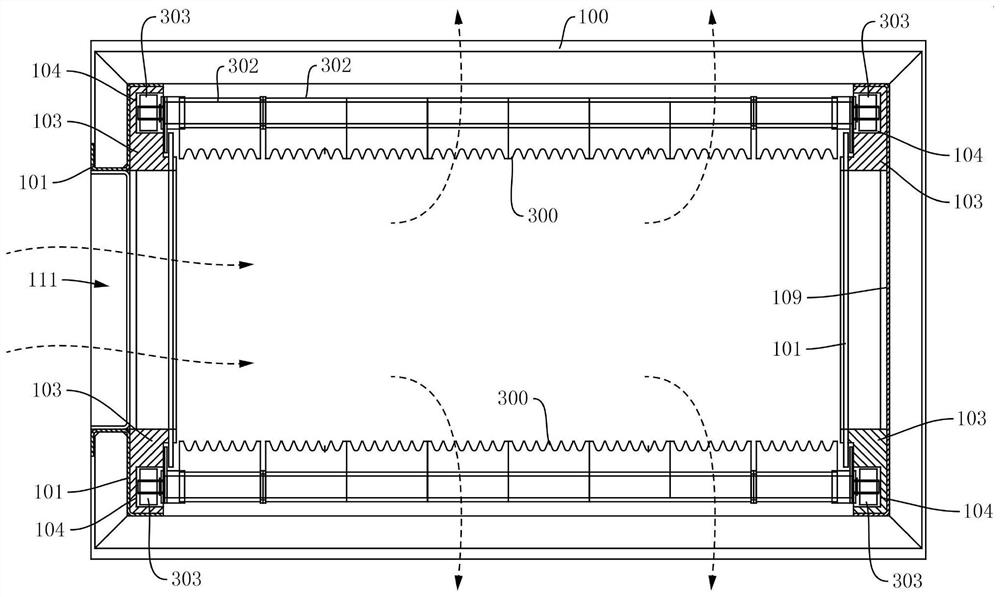

[0046] See Figure 1 - Figure 3 In this embodiment, a hole plate grid system includes a frame 100, a spindle 202 (or a chain axis), a hole plate chain 300, and power equipment 201, wherein

[0047] The rack 100 is mainly used to support support to mount and secure the remaining equipment, for example, in this embodiment, such as figure 1 and figure 2 As shown, the frame 100 includes a frame 101, and the frame 101 can be made of a conventional profile, for example, the frame 101 can preferentially adopt a rectangular structure in order to form an internal cavity 112 in the frame 101, such as figure 1 As shown, in actual operation, the lower portion of the frame 101 typically does not enter the water, and the upper portion of the frame 101 is typically located above the water surface to provide the main shaft 202, the power device 201, the flushing system, and the slag system, etc., the upper portion of the frame 101 Usually, a housing 102 is typically provided to enclose the interna...

Embodiment 2

[0070] The sealing problem between the sealing member 400 and the adjacent orifice plate 302, the main difference from the above-described Embodiment 1 is that in the orifice plate grid system provided in the present embodiment, the first sealing plate 401 or Side of the reinforcing strip 402 is constructed with parallel limiting convex 408, such as Figure 5 - Figure 10 As shown, the limiting projection 408 can preferentially employ a strip structure, and the two resilient projections 408 have a set distance for insertion of one side of the orifice plate 302. In the actual assembly, since the hole plate 302 is constrained between the adjacent two-way shaft 301, the sealing member 400 is just located on one side of the orifice plate 302 when the sealing member 400 is directly constrained by the adjacent two-way shaft 301. Figure 9 and Figure 10 As shown, at this time, the side of the orifice plate 302 can be inserted between the two limit projections 408, one aspect such that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com