Full-automatic sewage concentration treatment equipment and treatment method

A treatment equipment and fully automatic technology, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of low concentration of sewage, large proportion of sewage in desilter, Unstable water content and other problems, to achieve the effect of high sewage concentration efficiency and multiples, short sewage concentration time, and stable sewage mud content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

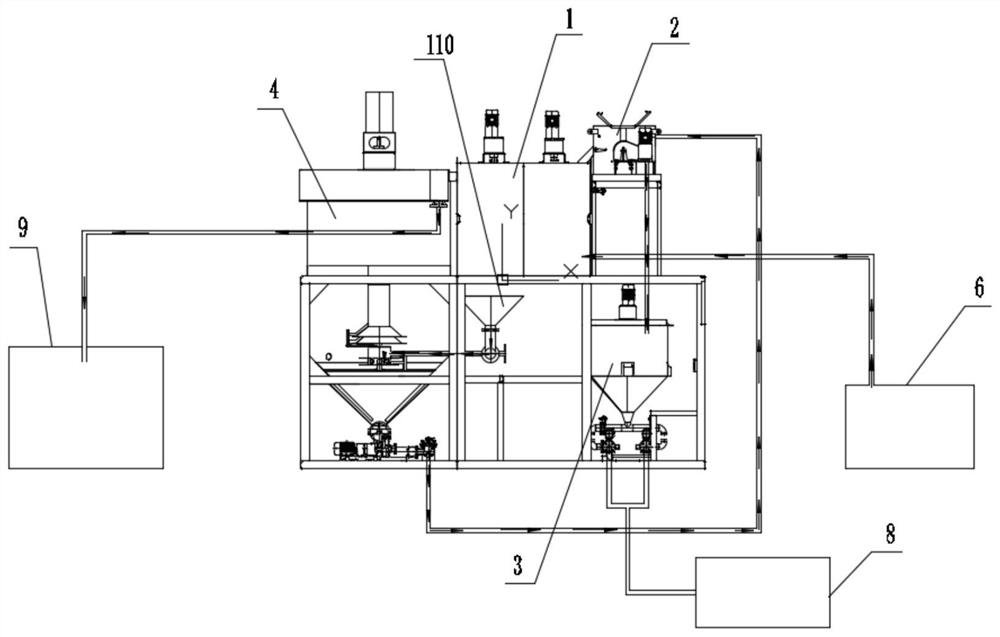

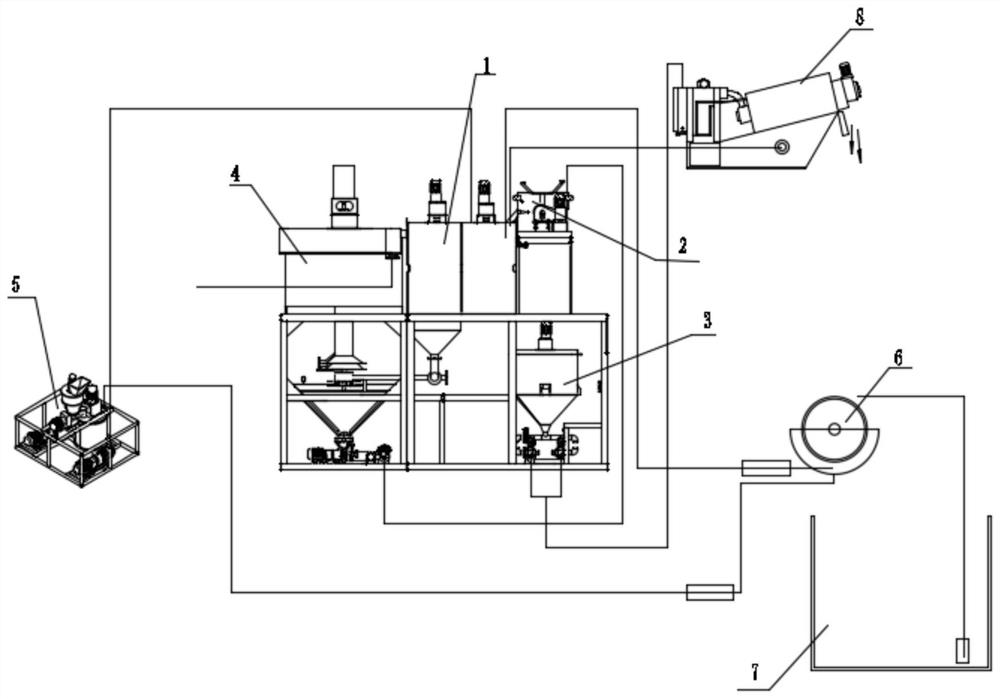

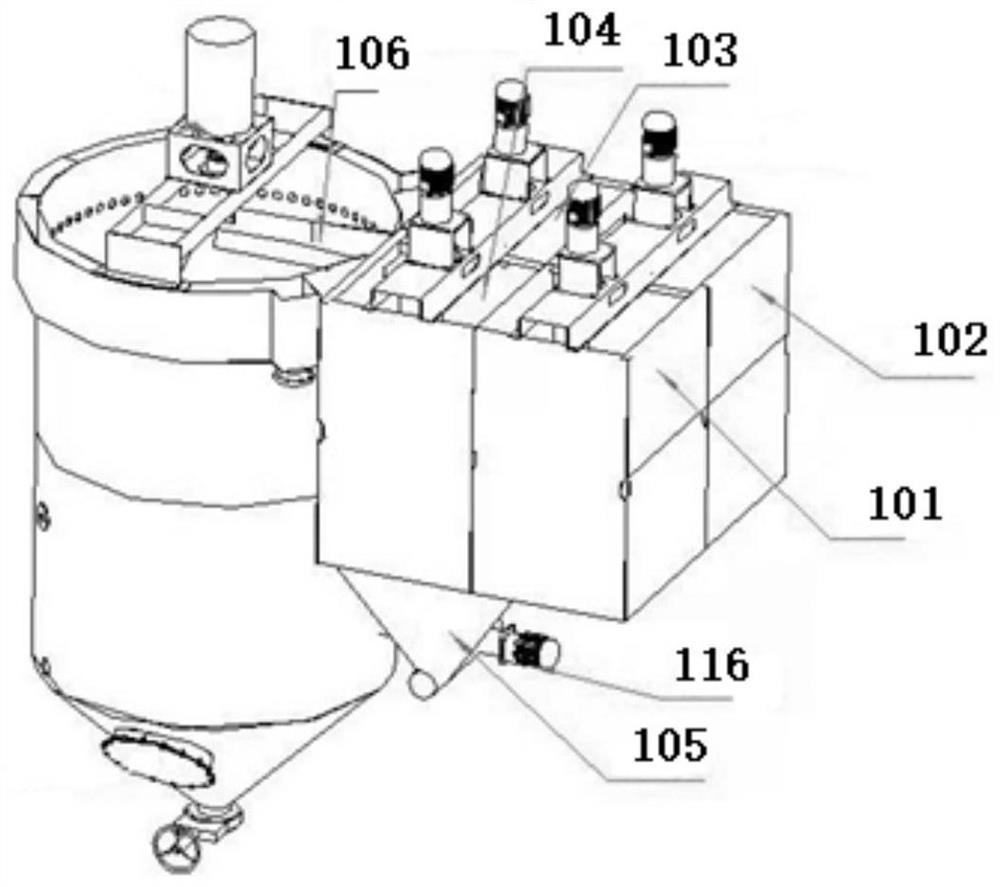

[0055] see Figure 1-17 , the present invention provides fully automatic sewage concentration treatment equipment, including a pre-separation stirring tank 1, an aerated magnetic separator 2, a concentrated sewage tank 3, a sedimentation tank 4 containing a plug-flow screw, a magnetic powder dosing system 5, and a drum filter Device 6, sewage tank 7, deslimer 8. Pre-separation stirring tank 1, aeration type magnetic separator 2, concentrated sewage tank 3, sedimentation tank with plug-flow screw 4, magnetic powder dosing system 5, drum filter 6 and deslimer 8 are all connected to the PLC controller . The deslimer 8 is a stacked screw deslimer. The pre-separation stirring tank 1, the aeration type magnetic separator 2, the magnetic powder dosing system 5, the sedimentation tank 4 containing the plug-flow screw, the drum filter 6, the concentrated sewage tank 3 and the deslimer 8 are all controlled by PLC device connection.

[0056] A kind of pre-separation stirred tank 1 co...

Embodiment 2

[0085] This embodiment differs from Embodiment 1 in that:

[0086] Shaftless helical screw I and shaftless helical screw II include the following weight fraction raw materials: the content of B is 12%, the content of Mo is 20%, the content of Cr is 10%, the content of C is 1%, and the content of V is 3% %, the content of Nb is 2%, the content of W is 5%, the content of Ce is 0.5%, the content of Mn is 5%, the content of Ni is 12%, and the balance is Fe. The powder degree of Cr is 30 μm; the powder degree of Mn is 50 μm. The purity of Mo is above 99.8%, the purity of B is above 99.7%, the purity of Cr is above 99.8%, the purity of Ni is above 99.5%, the purity of Mn is above 99.5%, and the weight ratio of Mo, Ni and B is 1.5:1:1.

Embodiment 3

[0088] This embodiment differs from Embodiment 1 in that:

[0089] Shaftless helical screw I and shaftless helical screw II include the following weight fraction raw materials: the content of B is 12%, the content of Mo is 20%, the content of Cr is 10%, the content of C is 1%, and the content of V is 3% %, the content of Nb is 2%, the content of W is 5%, the content of Ce is 0.5%, the content of Mn is 5%, the content of Ni is 12%, and the balance is Fe. The powder degree of Cr is 13 μm; the powder degree of Mn is 20 μm. The purity of Mo is above 99.8%; the purity of B is above 99.7%; the purity of Cr is above 99.8%; the purity of Ni is above 99.5%; the purity of Mn is above 99.5%; the weight ratio of Mo, Ni and B is 0.4:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com