Steel-recycled concrete composite beam component with composite structure

A technology of recycled concrete and composite beams, which is applied in the direction of load-bearing elongated structural components, building components, building structures, etc., can solve problems such as large crack widths, increase the flexural bearing capacity, and increase the degree of connection , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

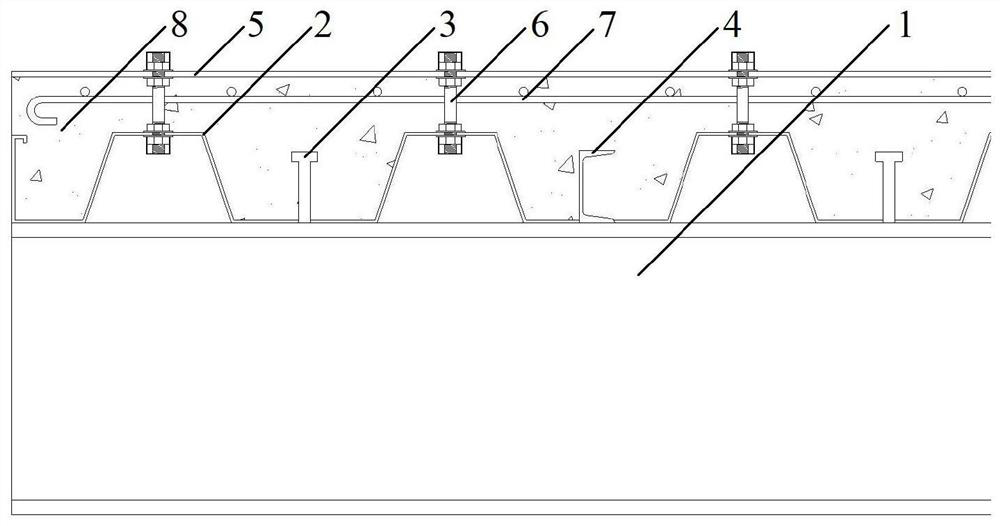

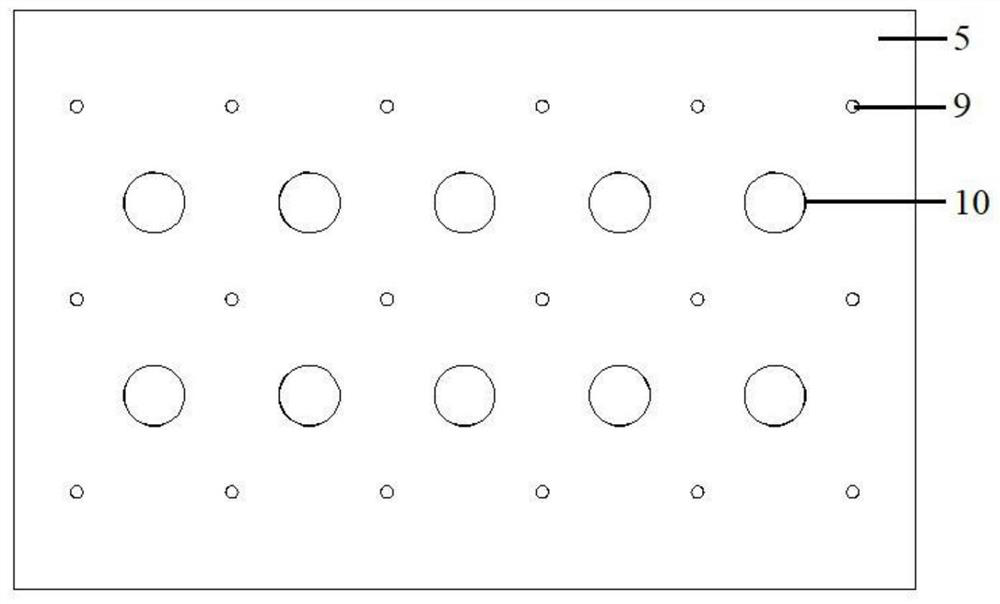

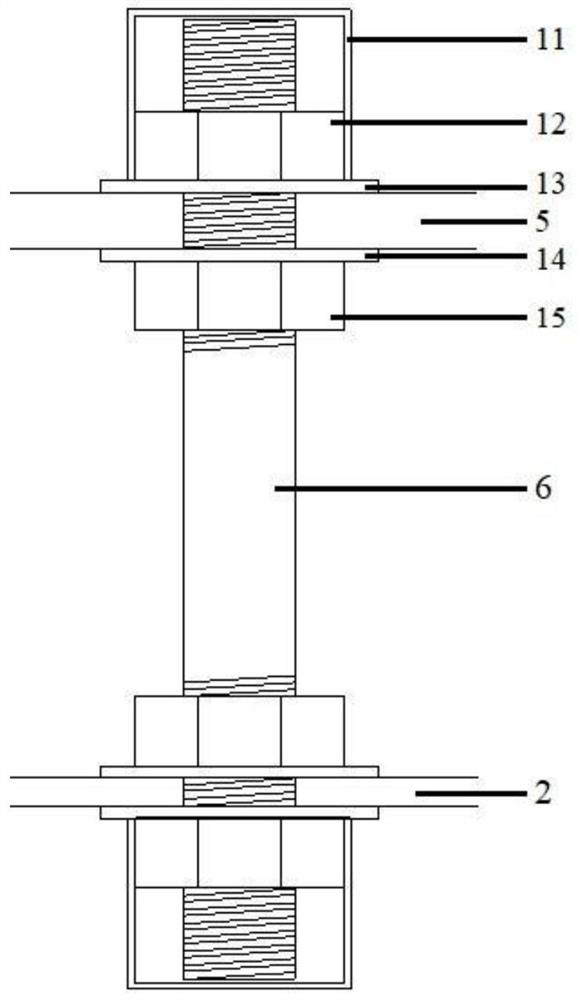

[0031] Specific implementation mode one: see Figure 1-5 This embodiment will be described. The steel-recycled concrete composite beam member with a composite structure described in this embodiment includes a steel beam 1, an open profiled steel plate 2, a stud connector 3, a channel steel connector 4, a tensile steel plate 5, and tie bolts 6. Reinforcement mesh 7 and recycled concrete 8, the upper surface of the steel beam 1 is welded with stud connectors 3 and channel steel connectors 4, and welded with the corresponding position of the open-type profiled steel plate 2, and the recycled concrete 8 is located in the open-type Between the profiled steel plate 2 and the tensile steel plate 5, the recycled concrete 8 is embedded with a steel mesh 7, the upper part of the tie bolt 6 is bolted to the tensile steel plate 5, and the lower part is connected to the upper convex part of the open profiled steel plate 2. Bolted.

[0032] The slenderness ratio of the stud connector 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com