Spray hole prevention drilling, cutting and punching drill tool for crossing hole of outburst coal seam

A technology of drilling through layers and protruding coal seams. It is applied in the direction of liquid/gas jet drilling, drill bits, drill pipes, etc., and can solve the problems of gas overrun in injection holes, so as to ensure the permeability and uniform coal output of drilling holes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

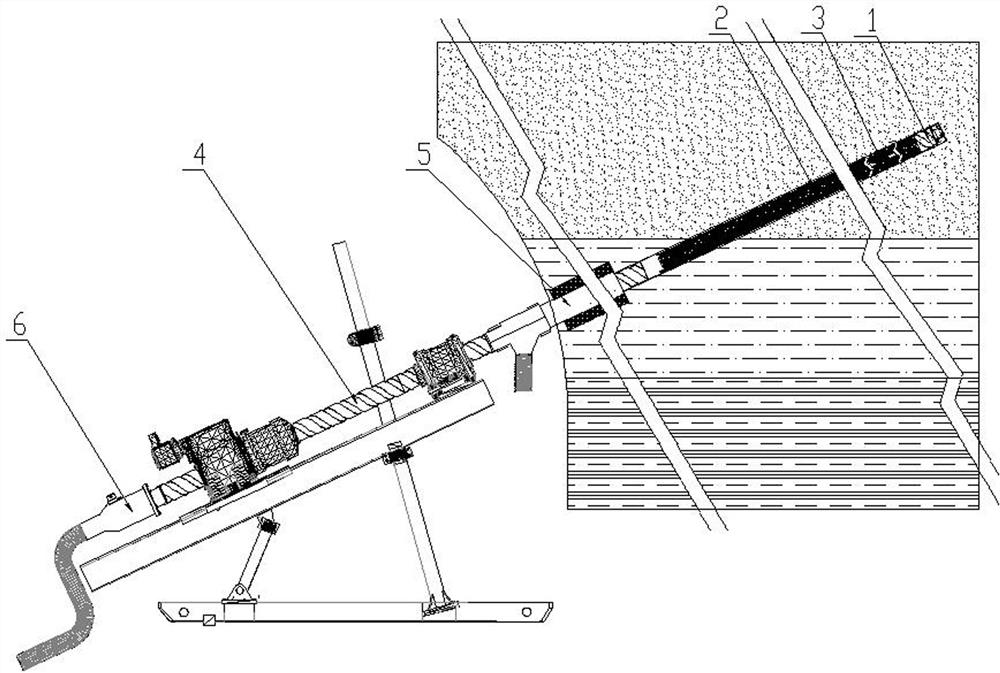

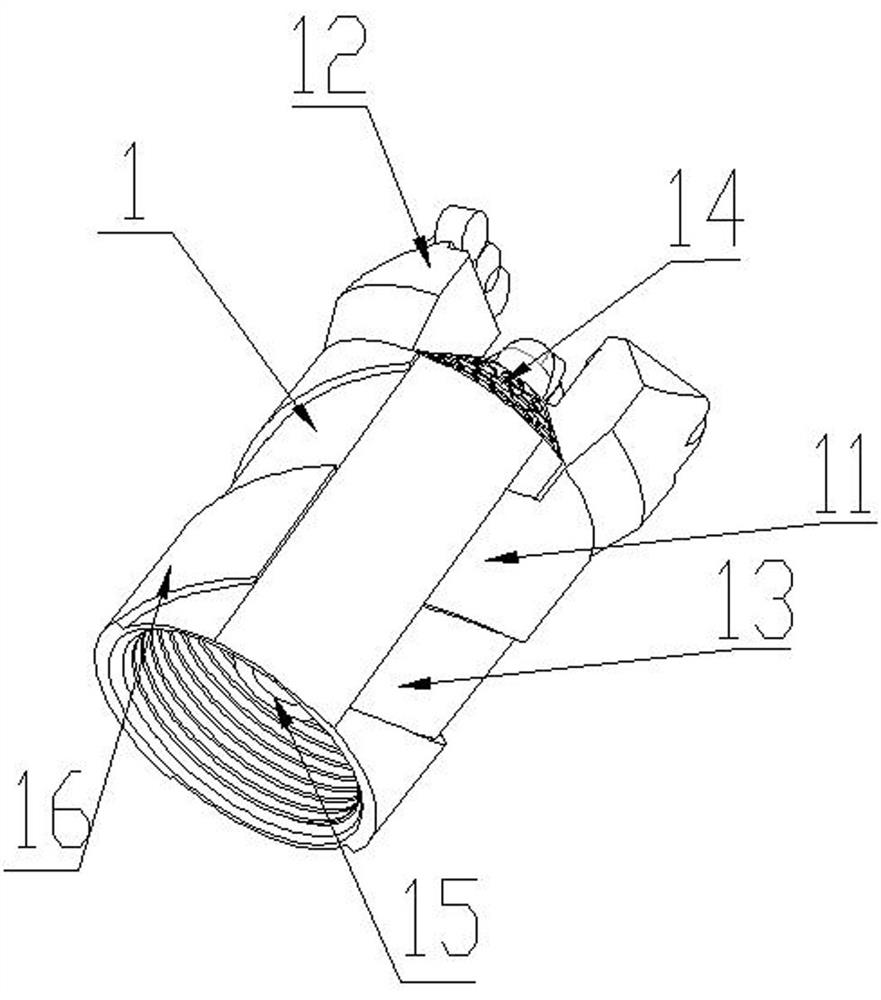

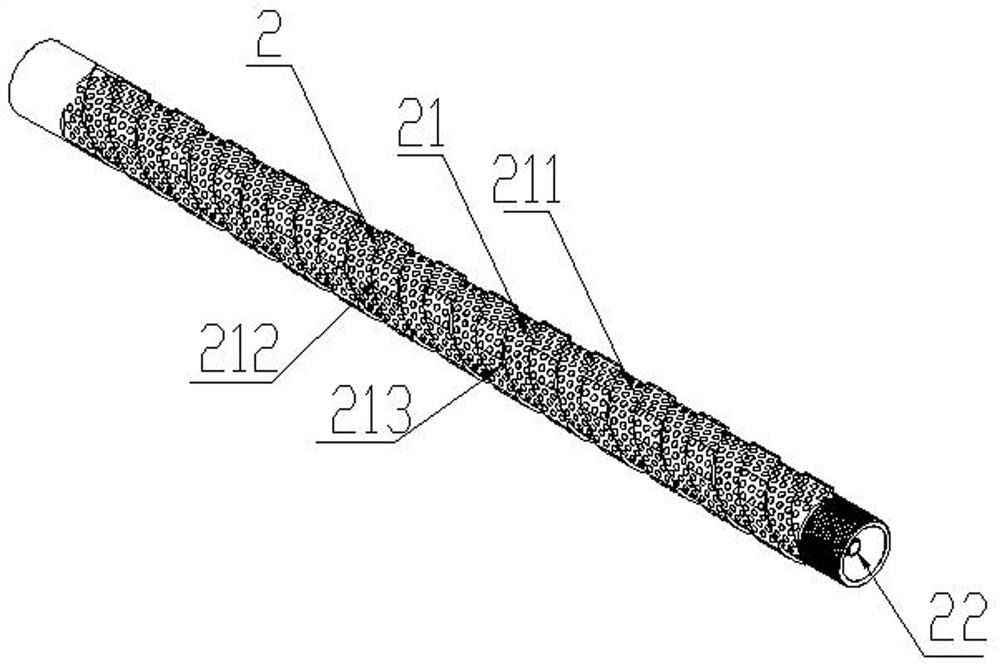

[0043] Such as Figure 1-14 As shown in the figure, a blowout prevention hole drilling, cutting and punching drilling tool for outburst coal seam penetration drilling includes a double-channel sieve hole drill bit 1, a plurality of double-channel slag drill pipes 2, A plurality of dual-channel drill pipes 4 and drill tail water supply and slag discharge assemblies 6 are located at the opening end of the borehole, and an orifice sealing and slag discharge assembly 5 matched with the dual-channel slag drill pipe 2 or the dual-channel drill pipe 4 is installed. During work, first drill through the double-channel slag drilling rod 2 and the dual-channel sieve hole drill bit 1 in the rock layer. After the slag drill pipe 2 and the dual-channel sieve drill bit 1 enter the coal seam, the coal seam is cut and washed. During the whole process, the water supply and slag dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com