Device and method for picking up strong anchor rod on coal face

A technology of coal mining face and pick-up device, which is applied in the installation of bolts, mining equipment, earth-moving drilling, etc. The effect of strong operability, strong pickup force, and fast pickup speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

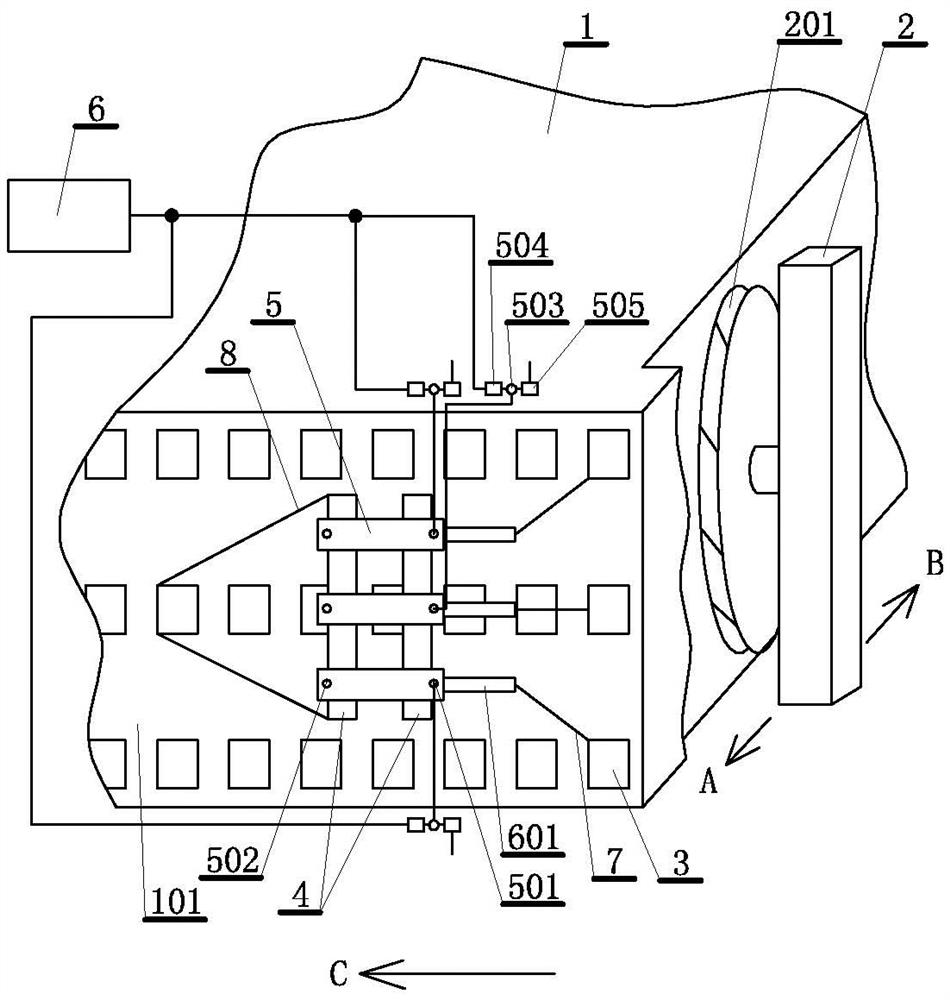

[0029] Strong anchor picking device, such as figure 1 As shown, the apparatus includes a steel anchor 31, side by side, and intervals inserted into the coal semicondrum, arranged, intervals, and a plurality of steel anchors, usually on each row of steel anchors. The middle and lower three, the anchor is used by the model of M18 * 2-type left-rotary steel anchor; the anchor is up and down 1200mm, the left and right spacings are 1000mm. The coal machine uses Mg650 / 1510-WD type, and the cutoff is 800mm. As the transverse direction of the coal machine from B to A, the interval inserted steel anchor 3 is detached from the coal seam under the tuning, each time to the end of A, returning to B in the direction of B in the lateral direction. At the end, it is further adjusted from the inward direction of C, and the steel anchor pickup is provided between the steel anchor and the rear interval with the row of steel anchors and rear intervals to be huddled from the inward. The steel anchor...

Embodiment 2

[0034] A strong anchor picking method of a coal coal, wherein the method is implemented based on the coal pickup surface of the coal coal surface of the first embodiment, and therefore, the content of the first embodiment is used in the present embodiment, such as an embodiment. 1 The apparatus includes a steel anchor that is inserted into the coal seam in the direction of the coal seam, and inserted into the direction of the coal machine, side by side, each row of steel anchor is provided with multiple, with the coal machine Dunction, and inserted the steel anchor inserted inserted into the coal seam, and a steel anchor pickup is provided between a row of steel anchors and rear intervals that are hit by the coal machine. The steel anchor pickup includes two support rods, and the two support rods are disposed in parallel, and a plurality of cylinders are fixed in parallel to the two support rods, and a gas pump is gas supply, and the number of cylinders is set up and down. The num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com