Vacuum tail gas safe combustion device for biodiesel raw material vacuum distillation

A biodiesel and combustion device technology, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems that can not fundamentally eliminate exhaust exhaust, affect the surrounding atmospheric environment, reduce emissions, etc., and achieve the elimination of sudden accidents Hidden dangers, elimination of accident safety hazards, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The vacuum tail gas safe combustion device for vacuum distillation of biodiesel raw materials of the present invention will be further described in detail below in conjunction with specific embodiments.

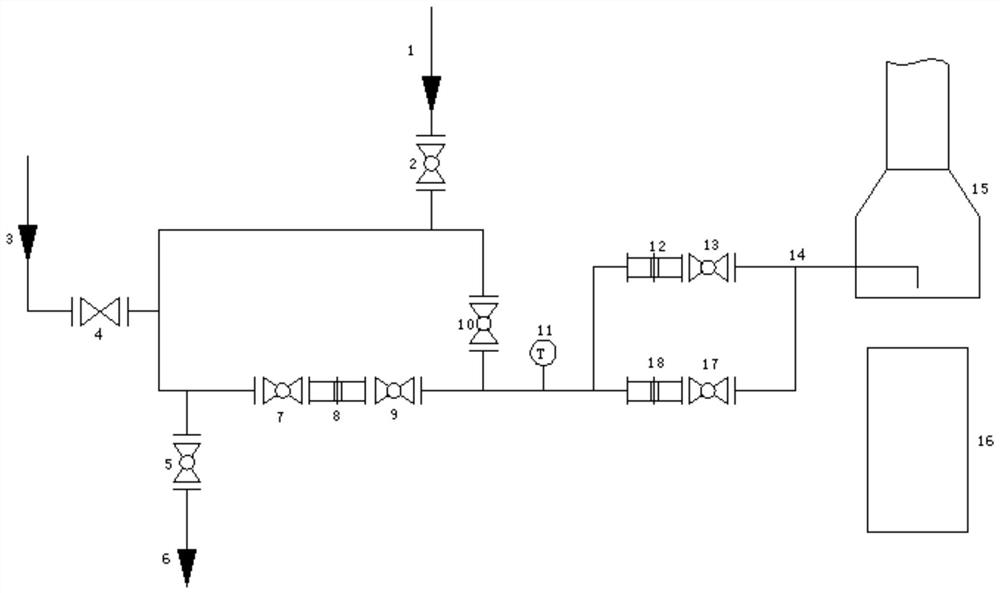

[0013] figure 1 As shown, the vacuum tail gas safe combustion device of the biodiesel raw material vacuum distillation of the present invention comprises a briquette furnace 16 with a tail gas combustion chamber 15, an explosion-proof temperature detection sensor PT100 thermal resistor 11, a flame arrester, pipelines and valves; Vacuum tail gas connection pipe 1 is divided into three pipes after connecting tail gas to ball valve 2, the first road is connected to condensate discharge ball valve 5 and drain collection pipe 6, the second road is connected to left ball valve 7, explosion-proof pipe resistance The firearm 8 and the right ball valve 9, the third road is connected with the bypass ball valve 10 and merged with the second road; the merged pipeline is divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com