Propulsion motor vibration monitoring/signal feedback device and method

A vibration monitoring and signal feedback technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, computer control, etc., can solve the problem that the vibration data acquisition card cannot meet the needs of active control of motor vibration, and achieve easy upgrade and maintenance, avoid salt The effect of fog corrosion, improving the effect of correction compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

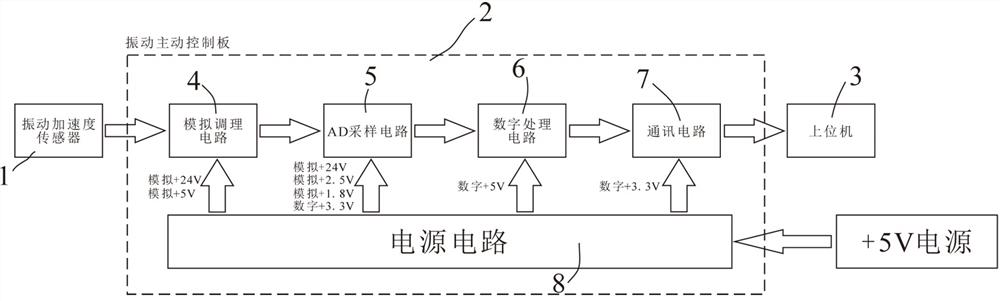

[0027] The embodiment of the present invention provides a propulsion motor vibration monitoring / signal feedback device, which is applied to the active control of ship propulsion motor vibration, and includes a vibration acceleration sensor 1 , an active vibration control board 2 and a host computer 3 .

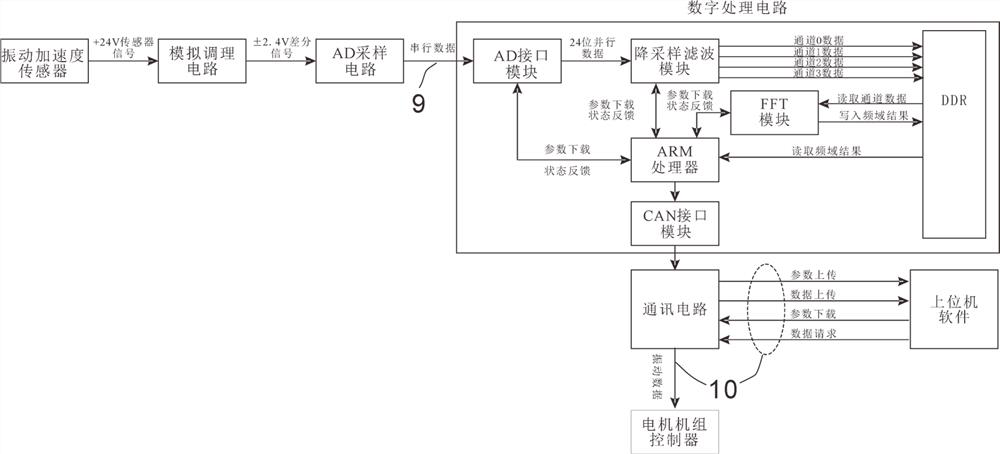

[0028] Such as figure 1 As shown, the hardware circuit of the active vibration control board 2 includes an analog conditioning circuit 4 , an AD sampling circuit 5 , a digital processing circuit 6 , a communication circuit 7 and a power supply circuit 8 . Embedded software includes data communication program, data acquisition program, FFT transformation program and data post-processing program.

[0029] The vibration acceleration sensor 1 collects the vibration acceleration signal of the motor and transmits it to the active vibration control board 2 through the SPI bus 9, and the vibration acceleration signal output by the vibration acceleration sensor 1 is input to the active...

Embodiment 2

[0045] Compared with the existing vibration acquisition card, the frequency resolution of the device is high, and the vibration frequency analysis range covers the main vibration frequency of the motor. Specifically, for example, the fundamental vibration frequency of a propulsion motor with a magnetic pole pair number of 14 and a rated speed of 180 r / min is about 42 Hz. The existing vibration acquisition card takes into account other applications, the frequency analysis range is usually greater than 0-8kHz, and the highest frequency resolution is greater than 100Hz. The vibration frequency analysis range of the device is 0 Hz to 1 kHz, covering the main vibration frequency range of the motor, and the highest frequency resolution is 0.5 Hz.

[0046] Compared with the existing vibration acquisition card, the device has higher precision when measuring the low-frequency vibration of the motor. Specifically, when the analog conditioning circuit of the device collects time-domain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com