Metal magnetic functional material capable of automatically controlling magnetic intensity and processing equipment of metal magnetic functional material

A technology of functional materials and processing equipment, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of low ignition point and low boiling point, and achieve the effect of wide applicability, high stability and easy change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

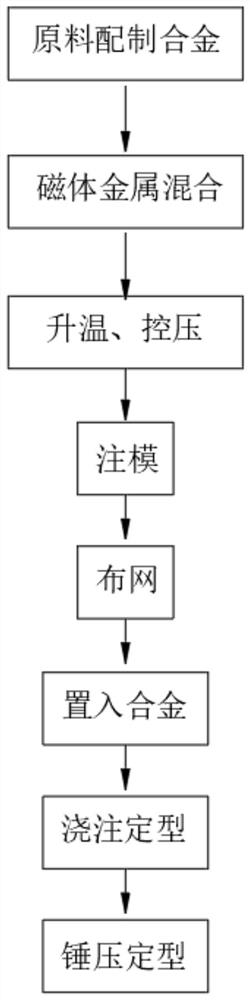

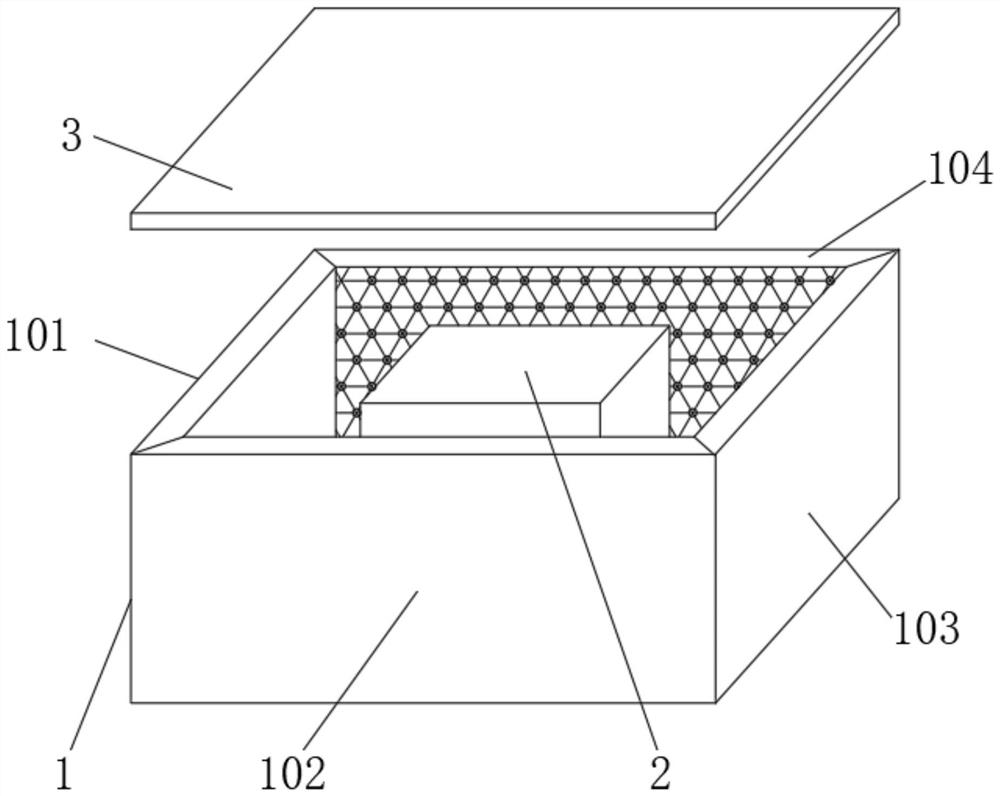

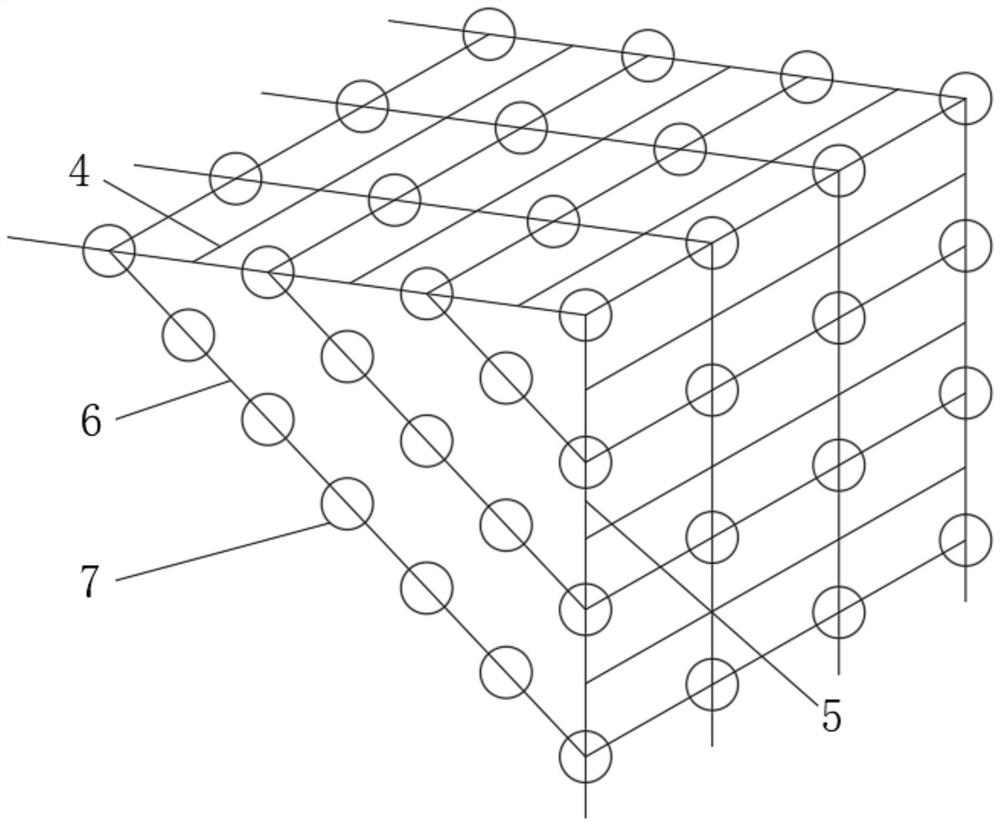

[0056] see Figure 1-4 , a metal magnetic functional material with self-controlled magnetic strength and its processing equipment, the processing steps include:

[0057] S1: Alloy prepared from raw materials;

[0058] Weigh metal iron, tin, and zinc, and the mass percentage of the three is 70:15:15, and configure it into a eutectic alloy with a low melting point.

[0059] S2: magnet metal mixing;

[0060] The manganese zinc iron oxide particles with a particle size of 15 nanometers are weighed and mixed with the configured low melting point alloy through a stirrer.

[0061] S3: temperature rise, pressure control;

[0062] Raise the temperature of the mixed raw materials to 300°C, control the pressure at -1.50MPa, start the mechanical stirring, first fast and then slow, so that the manganese zinc iron oxide particles are evenly dispersed in the low melting point metal, and the mass percentage of manganese zinc iron oxide is 19%. Paste magnetic functional materials.

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com