Blanking method for special-shaped flange of variable-frequency conveying flame-proof motor

A special shape, explosion-proof motor technology, applied in the direction of manufacturing motor generators, electrical components, electromechanical devices, etc., can solve the problems of difficulty, thickness, high power, etc., to save costs and ensure the effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical solution of the present invention easier to understand, the technical solution of the present invention will be described clearly and completely by means of specific embodiments in conjunction with the accompanying drawings.

[0020] The blanking method of the special-shaped flange of the frequency conversion conveying flameproof motor includes the following steps:

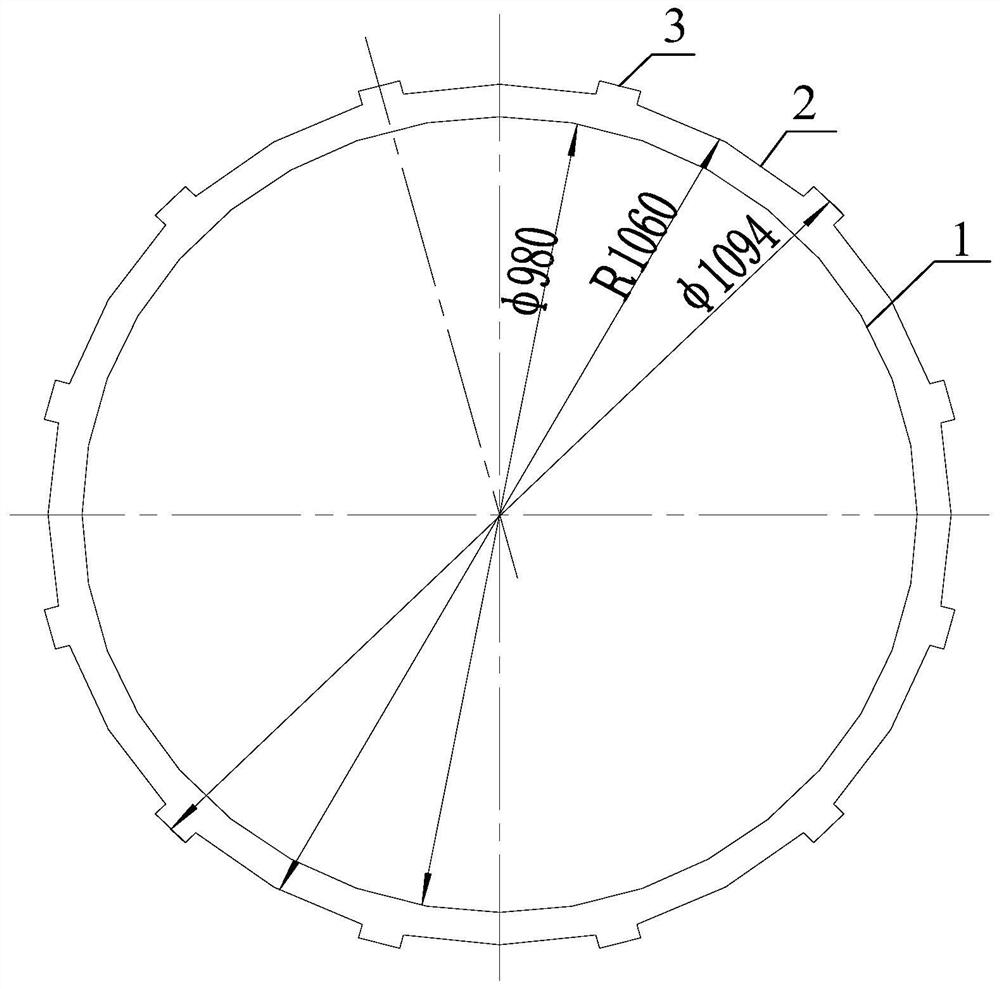

[0021] Step 1: Design the original drawing of the flange. The original drawing of the flange includes the inner circle, the outer circle and the flange shape straps. The diameters of the inner circle and the flange shape straps are all designed with allowances;

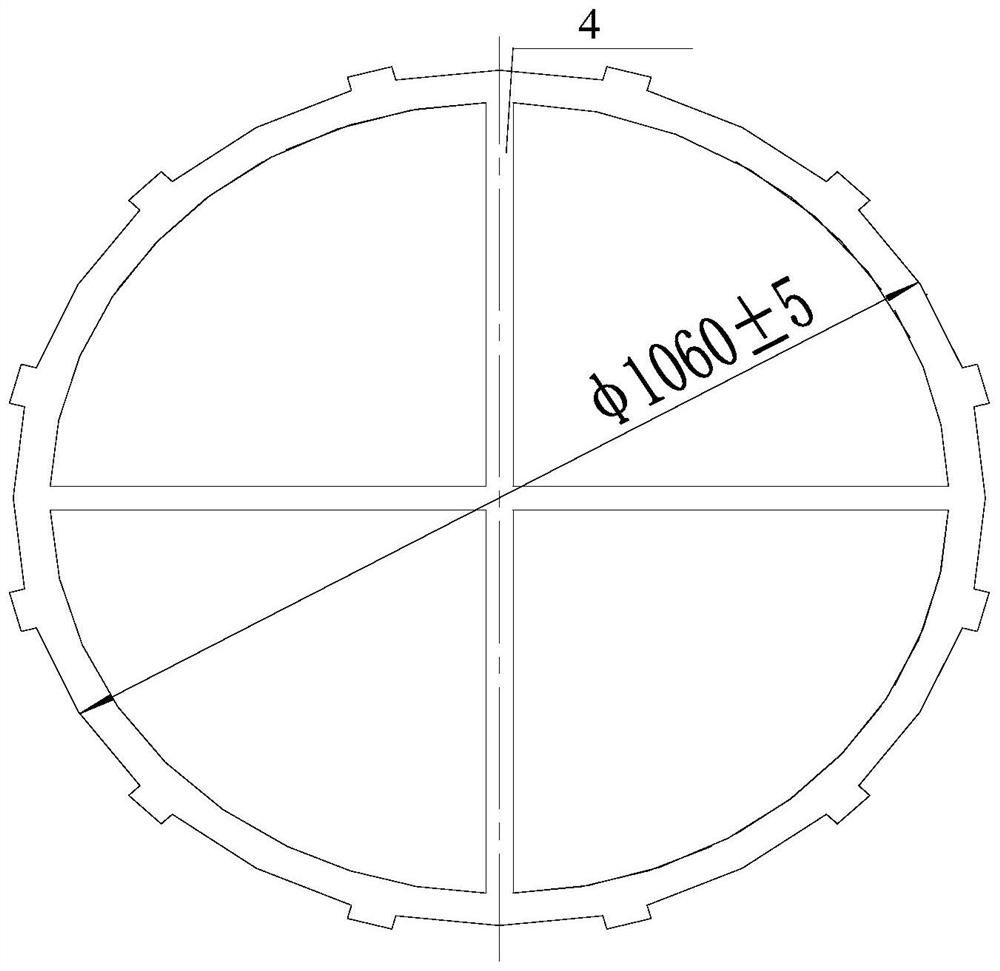

[0022] Step 2: There is no machining allowance for the outer circle, and when blanking, add process tension bars on the center line;

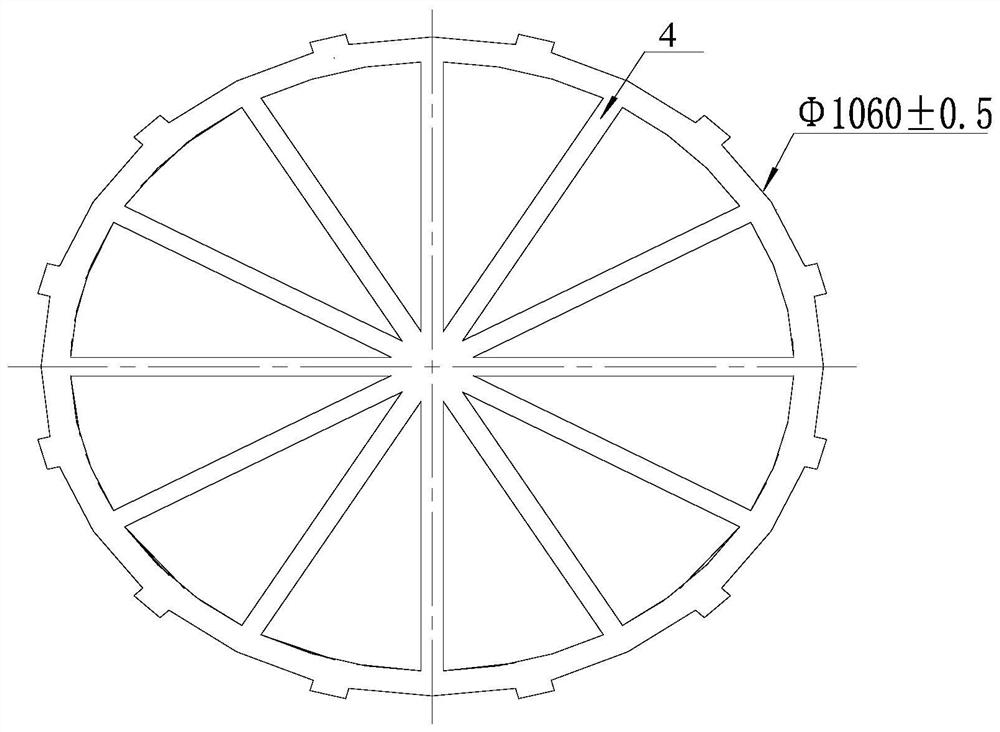

[0023] Step 3: After the blanking process cools down, the technical tie bars are cut off manually, and each root of the tie bars can be processed to the size of the drawing when the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com