Preparation method of modified-methyltris (methylethylketoxime) silane extraction separation auxiliary agent

A technology of methyl tributyl ketone oxime and silane, which is applied in the direction of liquid solution solvent extraction, chemical recovery, etc., can solve the problem of inability to achieve better separation effect and poor extraction and separation effect of modified-methyl tributyl ketoxime silane And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

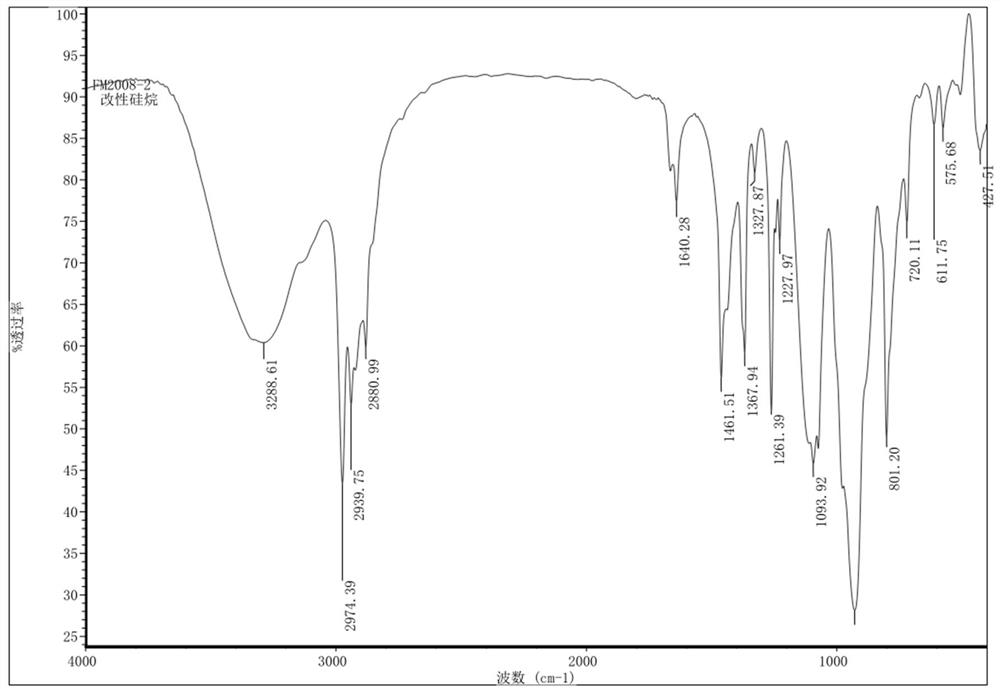

Image

Examples

Embodiment 1

[0028] A kind of preparation method of modified-methyl tributylketoxime base silane extraction separation aid, its operating steps are:

[0029] Add 52g of 2-vinylpyridine monomer into 100g of toluene solvent, stir and mix evenly, add 0.001g of metal complex catalyst, then stir and react at room temperature for 120min, then add 42g of cross-linking monomer, continue to stir for 45min, after completion Add 10g of ethanol to stop the reaction, remove the solvent under reduced pressure, add 10g of multi-block polyether, 0.2g of aluminate coupling agent, 2g of ethylene glycol, 10g of sodium benzenesulfonate, control the temperature at 60°C, stir for 30min, then add 1.5 g ammonium ricinoleate, 0.4 g naphtha and 10 g ammonia water, control the temperature to 90° C., and stir for 1 h to obtain the modified methyl tributylketoximosilane extraction and separation aid.

[0030] The preparation method of described multi-block polyether is as follows:

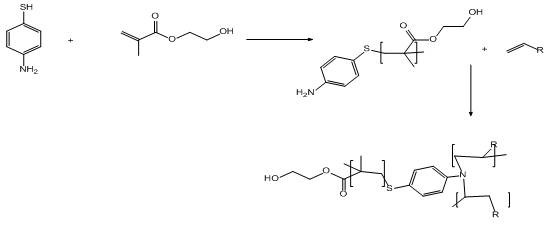

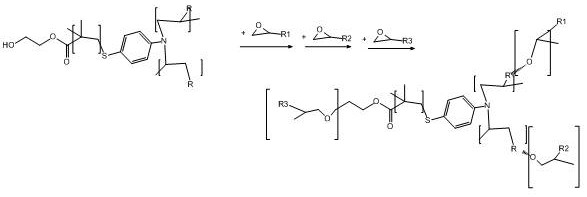

[0031] 1) Add 30g of p-aminothioph...

Embodiment 2

[0039]A kind of preparation method of modified-methyl tributylketoxime base silane extraction separation aid, its operating steps are:

[0040] Add 58g of 2-vinylpyridine monomer into 200g of toluene solvent, stir and mix evenly, add 0.005g of metal complex catalyst, then stir and react at room temperature for 150min, then add 54g of cross-linking monomer, continue to stir for 90min, after completion Add 15g of ethanol to stop the reaction, remove the solvent under reduced pressure, add 18g of multi-block polyether, 0.5g of aluminate coupling agent, 5g of ethylene glycol, 14g of sodium benzenesulfonate, control the temperature at 70°C, stir the reaction for 60min, then add 4.4 g ammonium ricinoleate, 1.6 g naphtha and 14 g ammonia water, temperature controlled to 95° C., stirred and reacted for 2 hours to obtain the modified-methyl tributylketoximosilane extraction and separation aid.

[0041] The preparation method of described multi-block polyether is as follows:

[0042] 1...

Embodiment 3

[0050] A kind of preparation method of modified-methyl tributylketoxime base silane extraction separation aid, its operating steps are:

[0051] Add 68g of 2-vinylpyridine monomer to 400g of toluene solvent, stir and mix evenly, add 0.01g of metal complex catalyst, then stir and react at room temperature for 180min, then add 64g of cross-linking monomer, continue to stir for 180min, after completion Add 20g of ethanol to stop the reaction, remove the solvent under reduced pressure, add 38g of multi-block polyether, 0.8g of aluminate coupling agent, 8g of ethylene glycol, 24g of sodium benzenesulfonate, control the temperature at 80°C, stir the reaction for 120min, then add 8.4 g ammonium ricinoleate, 3.6 g naphtha and 18 g ammonia water, temperature controlled to 100° C., stirred and reacted for 5 h to obtain the modified-methyl tributylketoximosilane extraction and separation aid.

[0052] The preparation method of described multi-block polyether is as follows:

[0053] 1) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com