Accurate welding device for lock catch longitudinal seams between small-diameter pipe roofing pipes and construction method

A technology for welding devices and small-diameter pipes, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of limited internal space and difficulty in horizontal connection of small-diameter curtain pipes, and overcome the complexity of longitudinal line changes and improve Effects of Lateral Stiffness and Integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

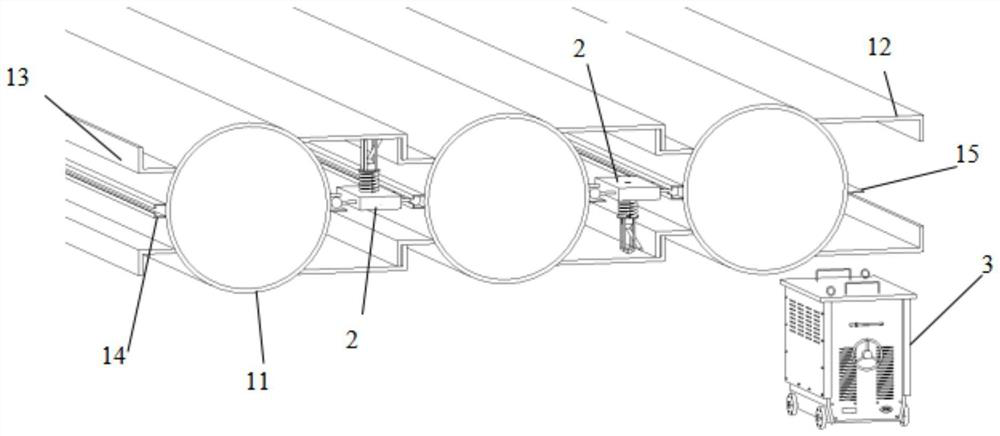

[0024] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

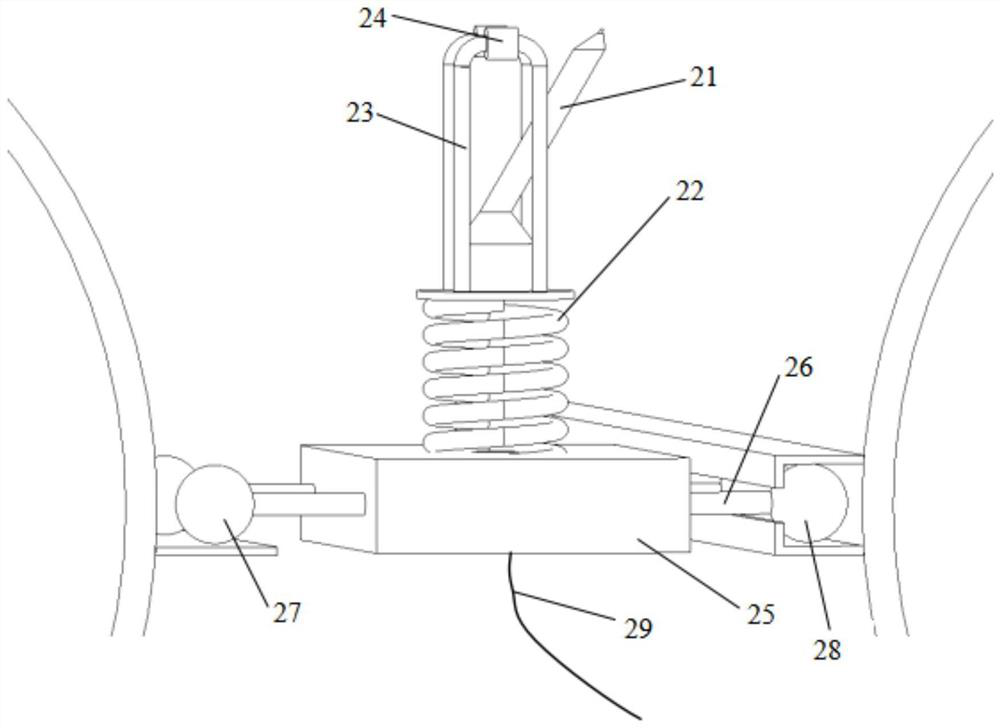

[0025] An embodiment of the present invention is a precision welding device for locking longitudinal seams between small-diameter pipe curtains, such as figure 2 As shown, it comprises: traveling motor 25, and the both sides of described traveling motor 25 are respectively provided with roller group, and described roller group comprises the fixed groove roller 27 that is located on the left side of traveling motor 25 and is located at traveling motor 25 right sides. The free groove roller 28 on the top, the fixed groove roller 27 and the free groove roller 28 are respectively connected with the output end of the traveling motor 25 through the roller shaft 26, and the traveling motor 25 drives the roller shaft 26 to work, and the roller shaft 26 drives the fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap