Preparation process of resin carbon fiber composite material

A fiber composite material and preparation process technology, applied in the coating and other directions, can solve the problems of lowering the overall heat resistance of the resin carbon fiber composite material, reducing the quality of the resin carbon fiber composite material, and the discoloration of the resin carbon fiber composite material. Poor heat resistance, good heat resistance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

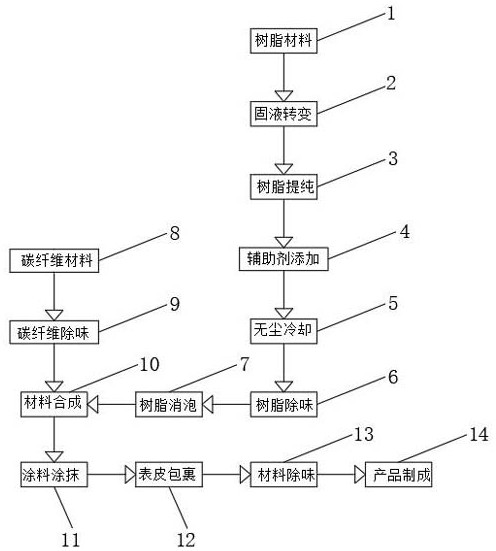

[0034] Embodiment one, by figure 1 , figure 2 and image 3 Given, a resin carbon fiber composite material preparation process of the present invention, resin material 1, solid-liquid transformation 2, resin purification 3, auxiliary agent addition 4, dust-free cooling 5, resin deodorization 6, resin defoaming 7, carbon fiber material 8 , carbon fiber deodorization 9, material synthesis 10, paint application 11, skin wrapping 12, material deodorization 13, product manufacturing 14;

[0035] Include the following steps:

[0036] S1: First, the resin raw material is heated, and the heated resin is converted from a solid substance to a liquid substance;

[0037] S2: Put the liquefied resin into a resin filter for filtration, thereby removing impurities in the liquefied resin and improving the purity of the resin;

[0038] S3: Add antioxidants and light stabilizers to the purified liquefied resin to avoid yellowing of the resin;

[0039] S4: Then put the purified resin into a...

Embodiment 2

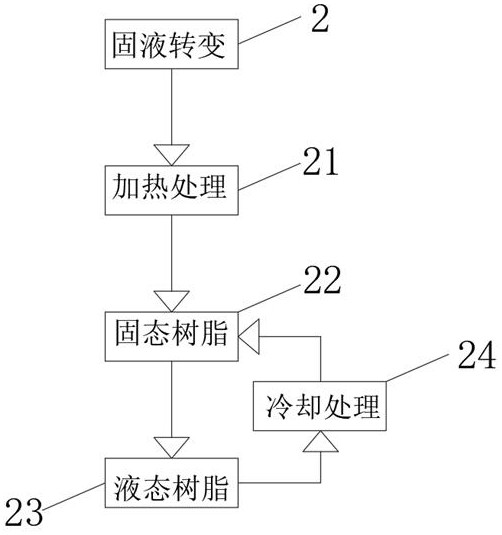

[0046] Embodiment 2, on the basis of Embodiment 1, the solid-liquid transition 2 includes heating treatment 21, solid resin 22, liquid resin 23, and cooling treatment 24. Through the setting of solid-liquid transition 2, the resin can be solidified and processed as required. The transformation of liquid state, so as to obtain better crafting materials.

Embodiment 3

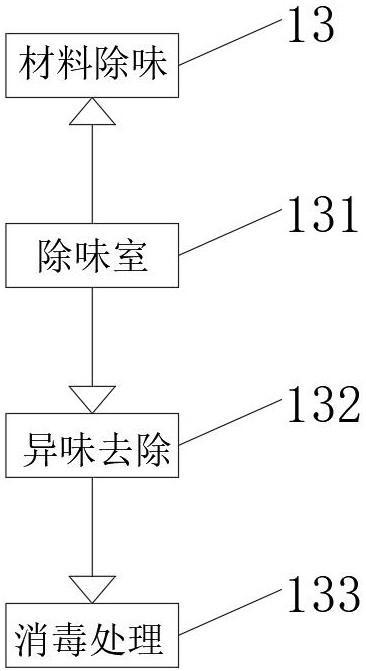

[0047] Embodiment 3. On the basis of Embodiment 1, the material deodorization 13 includes a deodorization chamber 131, a peculiar smell removal 132, and a disinfection treatment 133. Through the setting of the material deodorization 13, the peculiar smell produced by the finished material is eliminated. It is convenient for users to do work such as exhibitions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com