Hybrid power device, control system and automobile

A hybrid power and control system technology, which is applied in the field of control systems, automobiles, and hybrid power devices, can solve the problems of large axial and radial dimensions of the powertrain, inability to meet the requirements of longitudinal layout, and difficulties in platform application. Achieve the effects of small assembly size, reduced vehicle cost and supporting maintenance management cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

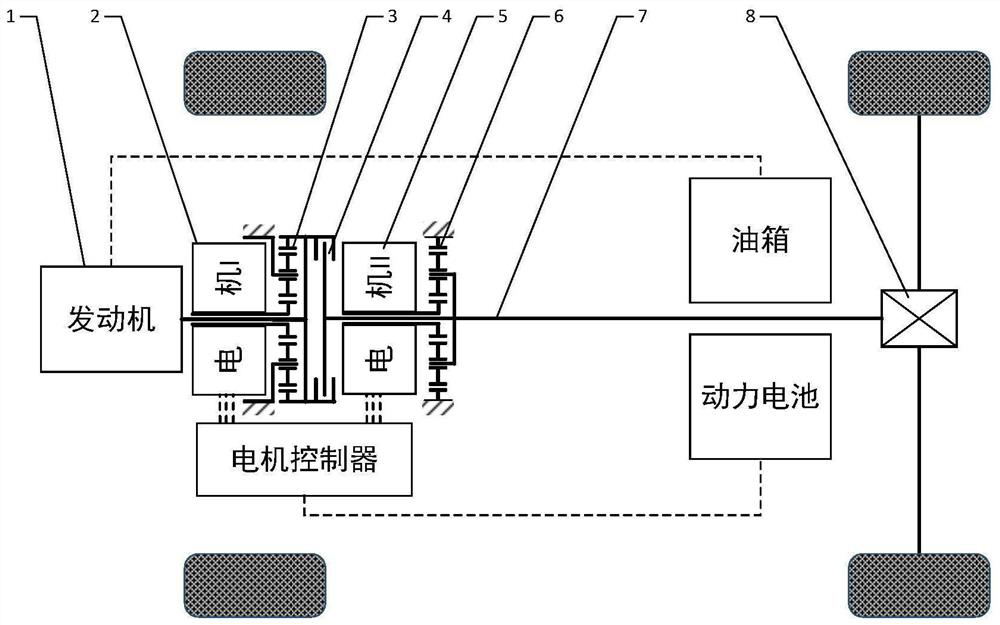

[0035] A hybrid power device provided by an embodiment of the present invention includes an engine 1 coaxially arranged, a first motor 2 and a second motor 5;

[0036] The power input shaft of the engine 1 is connected with the first planetary row 3 for providing power input;

[0037] The first motor 2 is connected with the sun gear of the first planetary row 3 for providing power input;

[0038] The second motor 5 is connected with the sun gear of the second planetary row 6 for providing power input;

[0039] The power transmission shaft 7 is configured to output power from at least one power source in the engine 1, the first motor 2 and the second motor 5 to the wheels to drive the wheels to rotate;

[0040] The clutch 4 is arranged between the first planetary row 3 and the power transmission shaft 7 , and is used to transmit power from the first planetary row 3 to the power transmission shaft 7 in a coupled state.

[0041] In this embodiment, the power input shaft of the ...

Embodiment 2

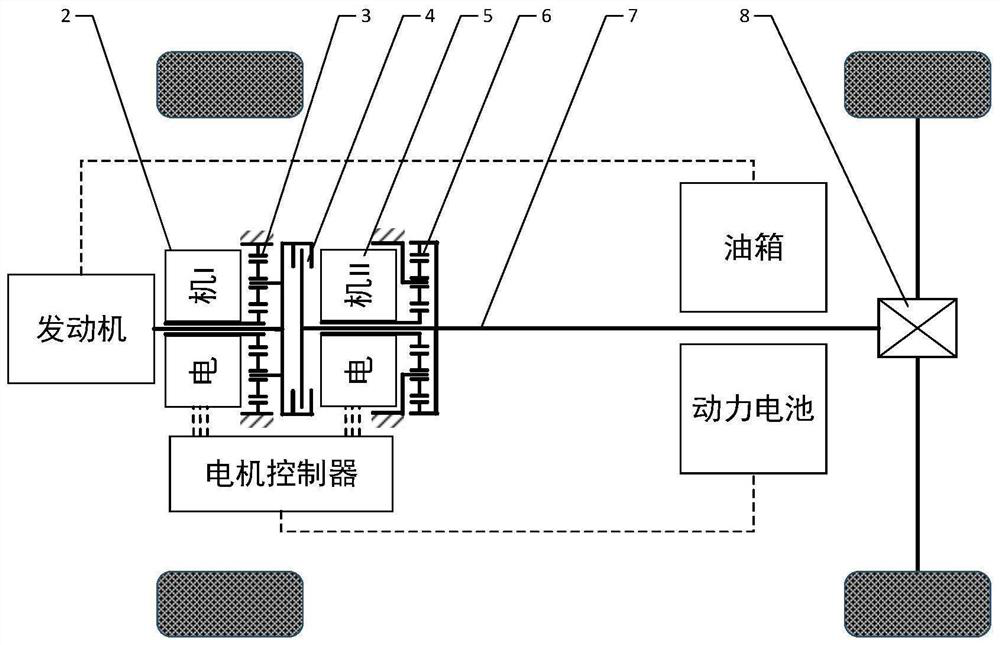

[0048] As an implementable way, on the basis of the above-mentioned embodiments, refer to the attached figure 1 It can be seen that a hybrid power device provided by an embodiment of the present invention includes an engine 1 coaxially arranged, a first motor 2 and a second motor 5;

[0049] The power input shaft of the engine 1 is connected with the first planetary row 3 for providing power input;

[0050] The first motor 2 is connected with the sun gear of the first planetary row 3 for providing power input;

[0051] The second motor 5 is connected with the sun gear of the second planetary row 6 for providing power input;

[0052] The power transmission shaft 7 is configured to output power from at least one power source in the engine 1, the first motor 2 and the second motor 5 to the wheels to drive the wheels to rotate;

[0053] The clutch 4 is arranged between the first planetary row 3 and the power transmission shaft 7 , and is used to transmit power from the first pla...

Embodiment 3

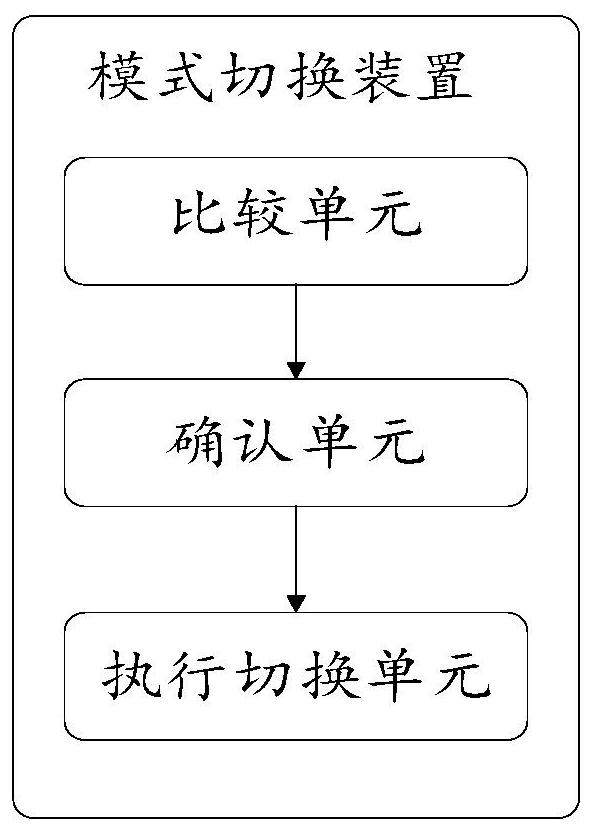

[0066] As an implementable way, on the basis of the above-mentioned embodiments, refer to the attached image 3 It can be seen that the embodiment of the present invention also provides a hybrid control system for driving a hybrid vehicle, including:

[0067] the aforementioned hybrid device, and

[0068] The mode switching device is used to determine the working mode of the hybrid power device according to the current battery power value (SOC or SOE) or / and the current speed of the car, the driver's demand torque or / and power, and switch the hybrid power device to the determined work The working modes include single-motor pure electric drive mode, dual-motor pure electric drive mode, engine 1 direct drive mode, series hybrid drive mode and parallel hybrid drive mode.

[0069] In some embodiments, the mode switching device also includes:

[0070] A comparison unit for comparing the current battery power value (SOC or SOE) with a first threshold, or / and comparing the current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com