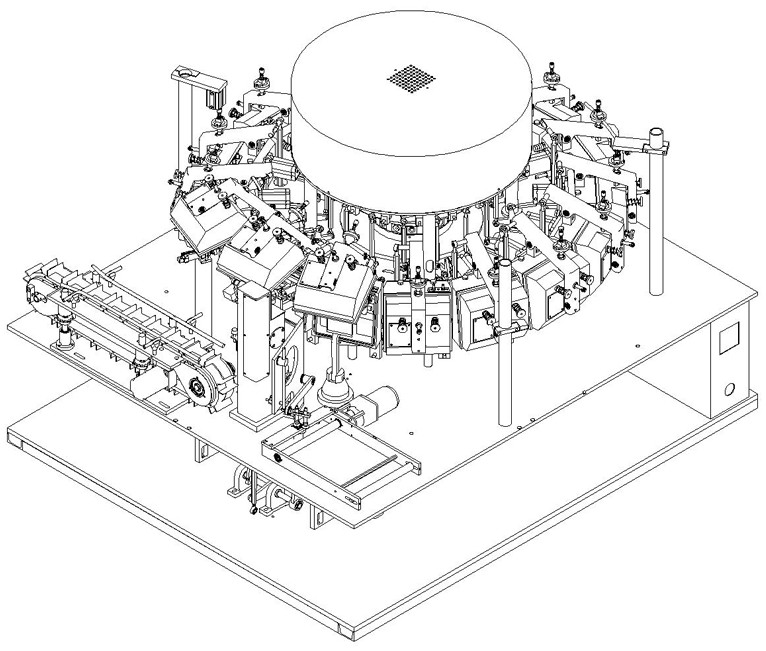

Lithium battery packaging machine

A packaging machine and lithium battery technology, applied in packaging machines, packaging, transportation packaging, etc., can solve the problems of long mold replacement cycle, affecting work efficiency, wasting packaging materials, etc., to save packaging materials, improve work efficiency, and improve production speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

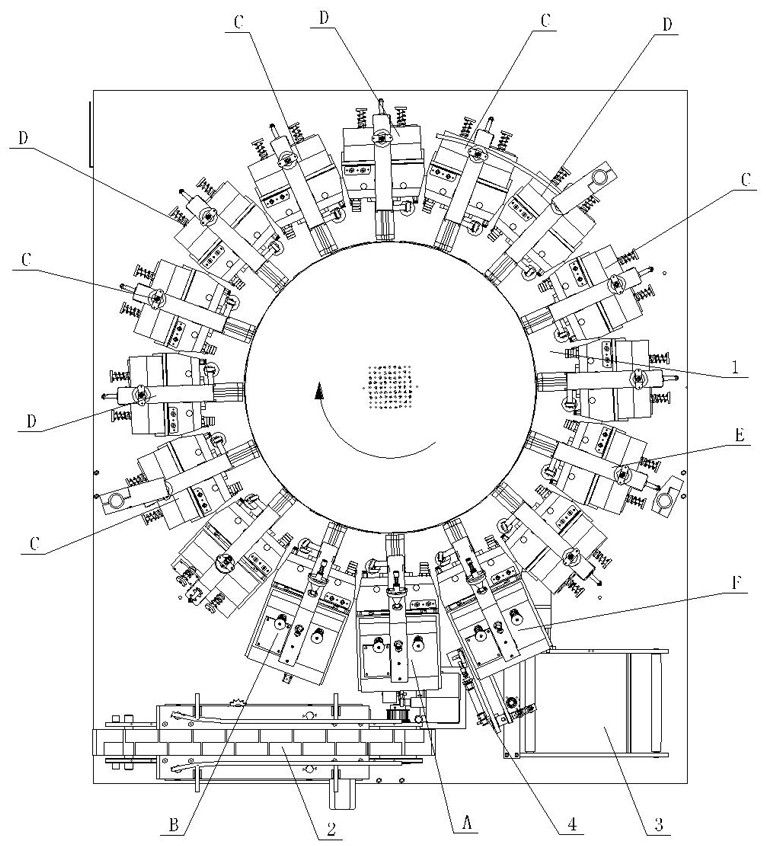

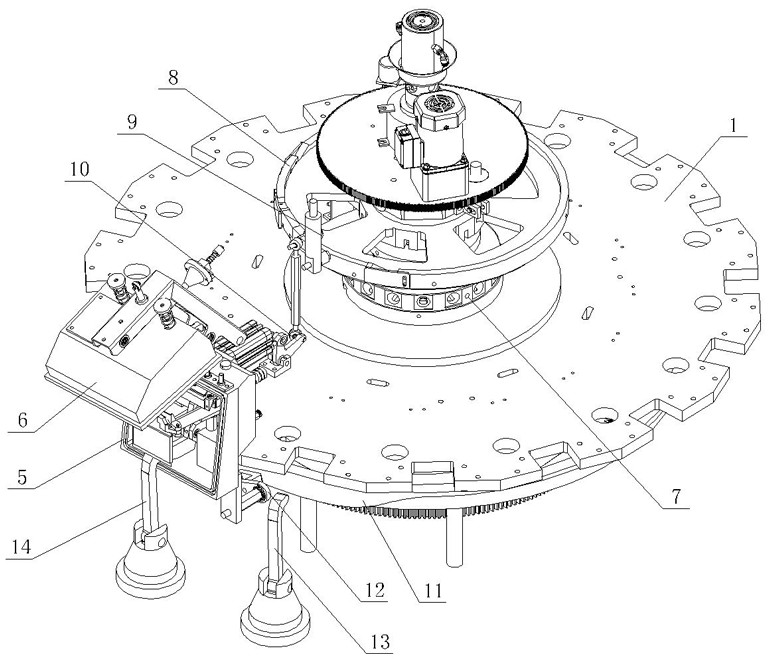

[0027] As shown in the figure, the lithium battery packaging machine of the present invention includes a closed-loop conveying track, the closed-loop conveying track is a circular track, and the circular track is formed by a turntable 1 for indexing rotation, and the outer circumference of the turntable 1 includes a bag loading station A. Bag opening station B, five vacuuming stations C, four filling and exhausting stations D, sealing station E and bag lowering station F, including sixteen stations, vacuum station C , Liquid filling and exhausting stations D are interspersed and arranged, and each station is correspondingly provided with a vacuum chamber assembly, and each vacuum chamber assembly is surrounded by a vacuum chamber body 5 and a vacuum chamber cover 6 to form a vacuum chamber, and the vacuum chamber body 5 and the vacuum chamber body The turntable 1 is fixedly connected, and the vacuum chamber cover 6 can be flipped on the vacuum chamber body 5. The vacuum chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com