A kind of modified graphene flame retardant containing flame retardant element and double bond and preparation method thereof

A graphene and flame retardant technology, applied in the field of flame retardants, can solve the problems of adverse effects of flame retardant properties, easy migration, easy migration of compounds, etc., and achieve the effect of good overall flame retardant effect, difficult migration, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

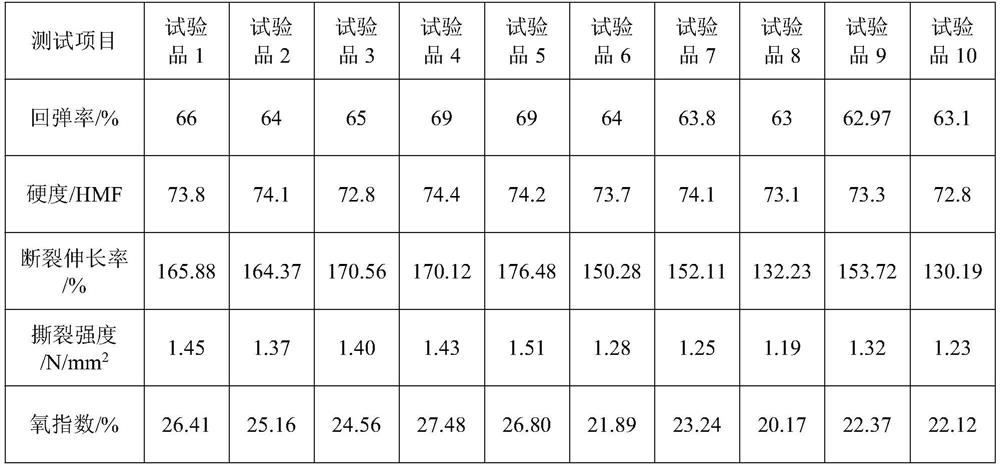

Examples

Embodiment 1

[0025] Embodiment 1: A modified graphene flame retardant containing flame retardant elements and double bonds. In parts by weight, first weigh 1 part of graphite flakes and 10 parts of sodium chloride for ball milling. The ball milling time is 1.5 hours; Then add 5 parts of p-aminostyrene and 10 parts of 6-pteridinamine, mix and ball mill for 1.5 hours; finally add 18.75 parts of nitrite, mix and grind for 24 hours, and the product obtained after washing and vacuum drying is the flame retardant element Modified graphene flame retardants with double bonds. The modified graphene flame retardant containing flame retardant elements and double bonds contains graphene, which is connected with 6-pteridine amine and p-aminostyrene through chemical bonds, and the modified graphite containing flame retardant elements and double bonds The alkene flame retardant can use the carbon-carbon double bond on p-aminostyrene to participate in the synthetic polyaddition reaction of the polymer pol...

Embodiment 2

[0026] Embodiment 2: A modified graphene flame retardant containing flame retardant elements and double bonds. In parts by weight, first weigh 1 part of graphite flakes and 10 parts of sodium chloride for ball milling. The ball milling time is 0.5 hours; Then add 5 parts of p-aminostyrene and 5 parts of 6-pteridinamine, mix and ball mill for 0.5 hours; finally add 12.5 parts of nitrite and mix and grind for 24 hours, and the product obtained after washing and vacuum drying is the product containing flame retardant elements Modified graphene flame retardant with double bonds, the modified graphene flame retardant containing flame retardant elements and double bonds contains graphene, which is connected with 6-pteridine amine and p-aminostyrene through chemical bonds, The modified graphene flame retardant containing flame retardant elements and double bonds can use the carbon-carbon double bonds on p-aminostyrene to participate in the synthesis and polyaddition reaction of polyme...

Embodiment 3

[0027] Embodiment 3: a kind of modified graphene flame retardant containing flame retardant elements and double bonds, by weight, first weigh 1 part of graphite flakes, 15 parts of sodium chloride are ball milled, and the ball milling time is 2 hours; Then add 10 parts of p-aminostyrene and 10 parts of 6-pteridinamine, mix and ball mill for 2 hours; finally add 25 parts of nitrite and mix and grind for 24 hours, and the product obtained after washing and vacuum drying is the flame retardant element Modified graphene flame retardant with double bonds, the modified graphene flame retardant containing flame retardant elements and double bonds contains graphene, which is connected with 6-pteridine amine and p-aminostyrene through chemical bonds, The modified graphene flame retardant containing flame retardant elements and double bonds can use the carbon-carbon double bonds on p-aminostyrene to participate in the synthesis and polyaddition reaction of polymer polyols, so that the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com