Automatic sanitary towel washing and screening equipment

A technology for screening equipment and sanitary napkins, which is applied to the configuration of textile materials processing equipment and cleaning devices for processing textile materials, etc. It can solve the problems of slow water discharge from the drain, increased labor costs, and multiple cleaning of the drain pipe, so as to ensure the flow rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

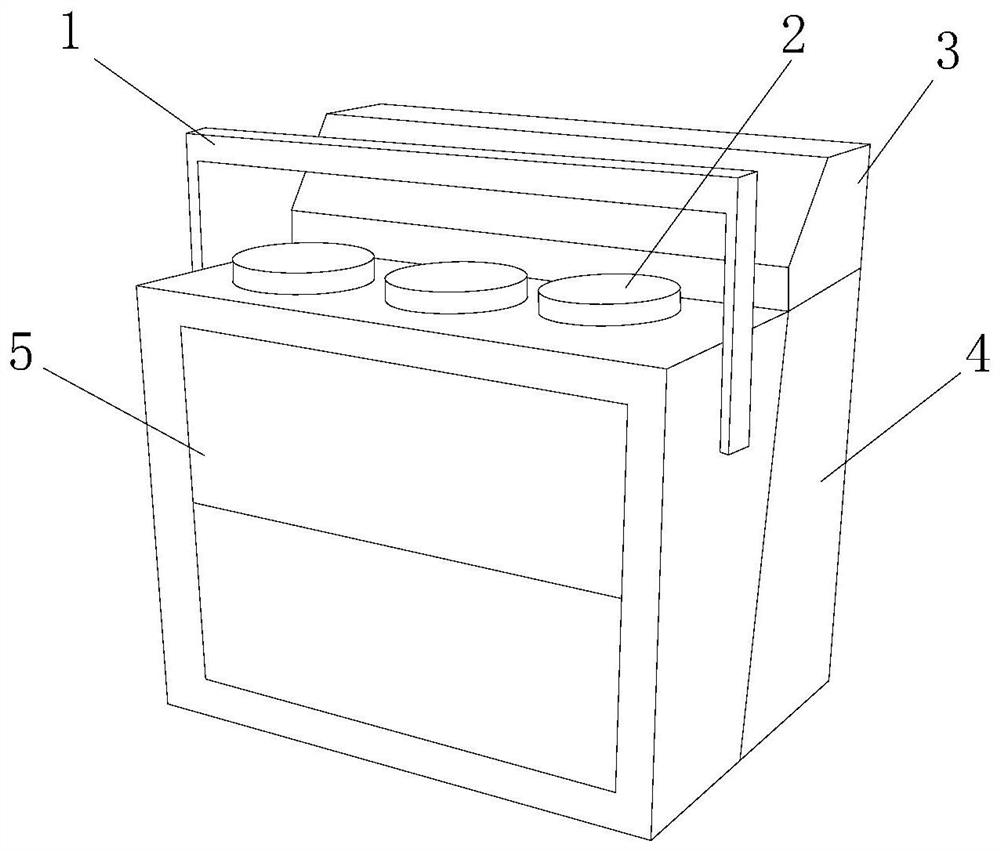

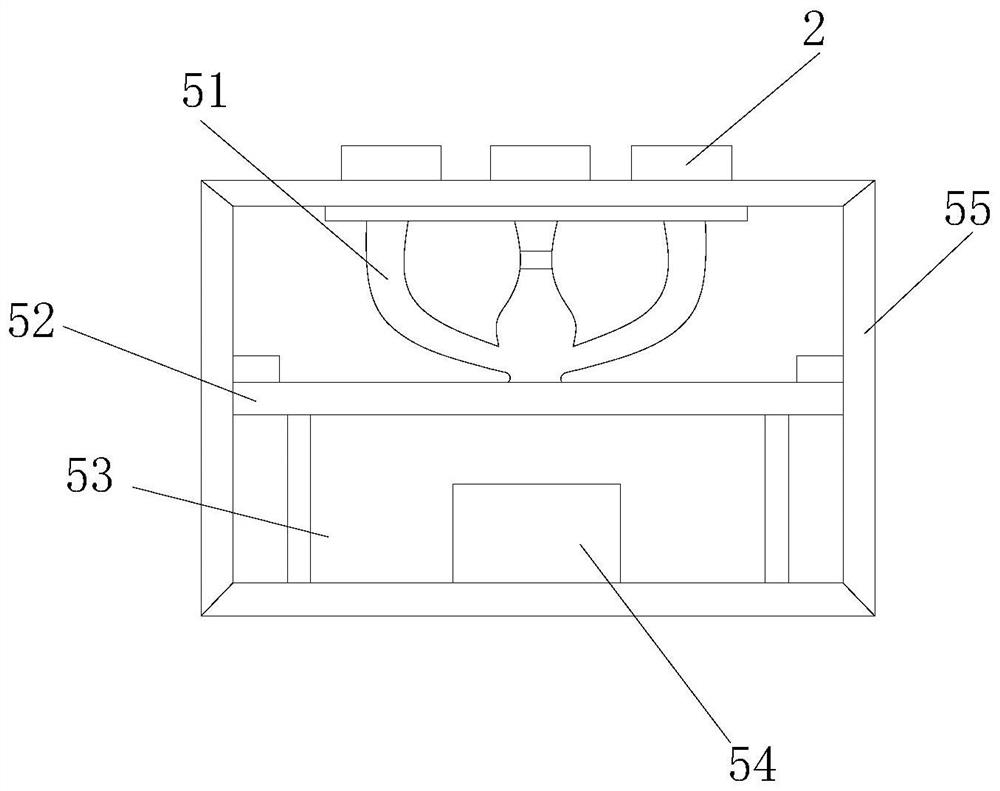

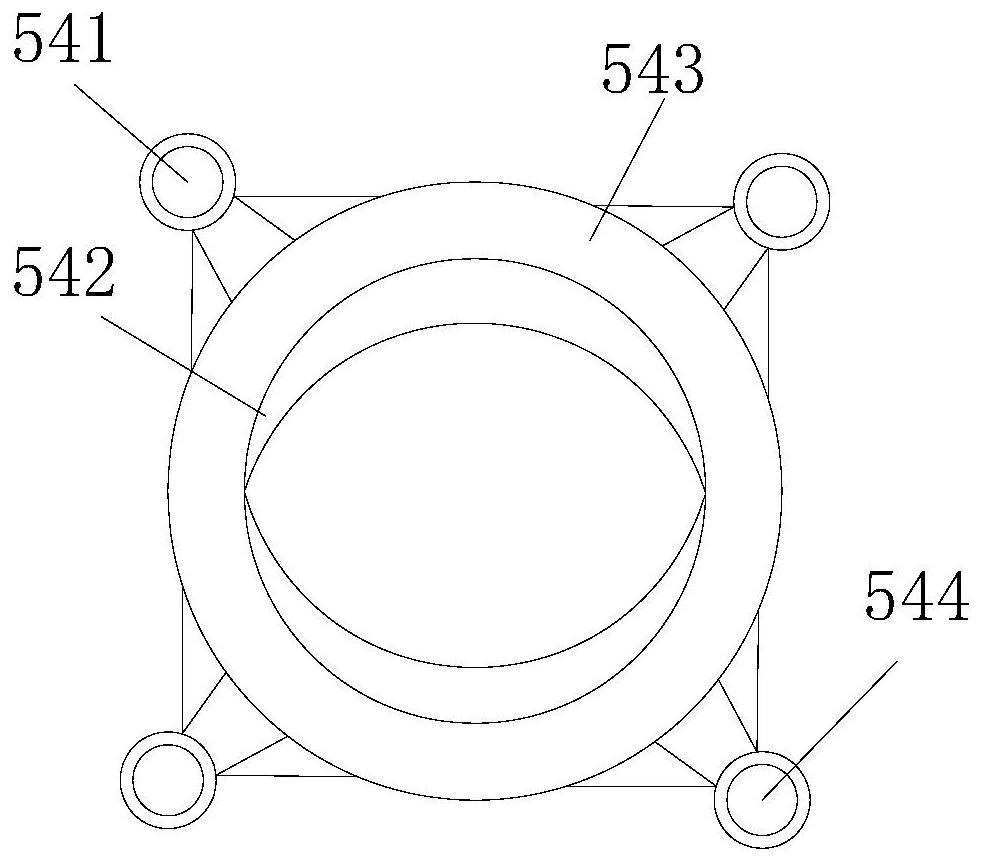

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides an automatic washing and screening device for sanitary napkins, the structure of which includes a handle 1, a transfer valve 2, an operating table 3, a washing host 4, and a filter mechanism 5. The handle 1 is welded to the filter mechanism 5, The filter mechanism 5 and the main washing machine 4 are indirectly cooperated through the transfer valve 2, and the transfer valve 2 and the operating table 3 are matched by an electrical connection. The filter mechanism 5 includes a branch pipe 51, a screen 52 , a reservoir 53, a drain 54, and a body 55, one end of the bifurcated pipe 51 is fixedly connected to the bottom of the transfer valve 2 through the body 55, and the other end is welded to the screen 52, and the bottom of the screen 52 is provided with a storage The pool 53 and the drain port 54, the drain port 54 includes a support column 541, a booster assembly 542, a partition ring 543, and a fixed co...

Embodiment 2

[0029] Such as Figure 5-Figure 8 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The shielding device 422 includes a set of scissors 22a1, a breaking body 22a2, a cutting piece 22a3, and a connecting plate 22a4. The set of scissors 22a1 The cutting pieces 22a3 are equidistantly arranged on the connecting plate 22a4, the connecting plate 22a4 is welded and connected to the breaking body 22a2, and the breaking body 22a2 is embedded and connected inside the middle grinding body 423, and the cutting piece 22a3 includes a top Support sleeve a31, elastic member a32, folding pole a33, cutting knife a34, and warping block a35, the cutting knife a34 is welded and connected to the inner side of the top support sleeve a31, and the top support sleeve a31 is socketed with two shears 22a1 side, and the back is obliquely inserted and connected with a support block a35, the support block a35 is indirectly m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com