Waterproof construction method for basement bottom plate and outer wall

A basement floor and construction method technology, applied in the field of exterior wall waterproof construction and basement floor, can solve the problems of difficulty in ensuring accuracy and quality, time-consuming and labor-intensive problems, reduce difficulty and cumbersomeness, reduce the number of workers, and the laying method is simple and practical Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

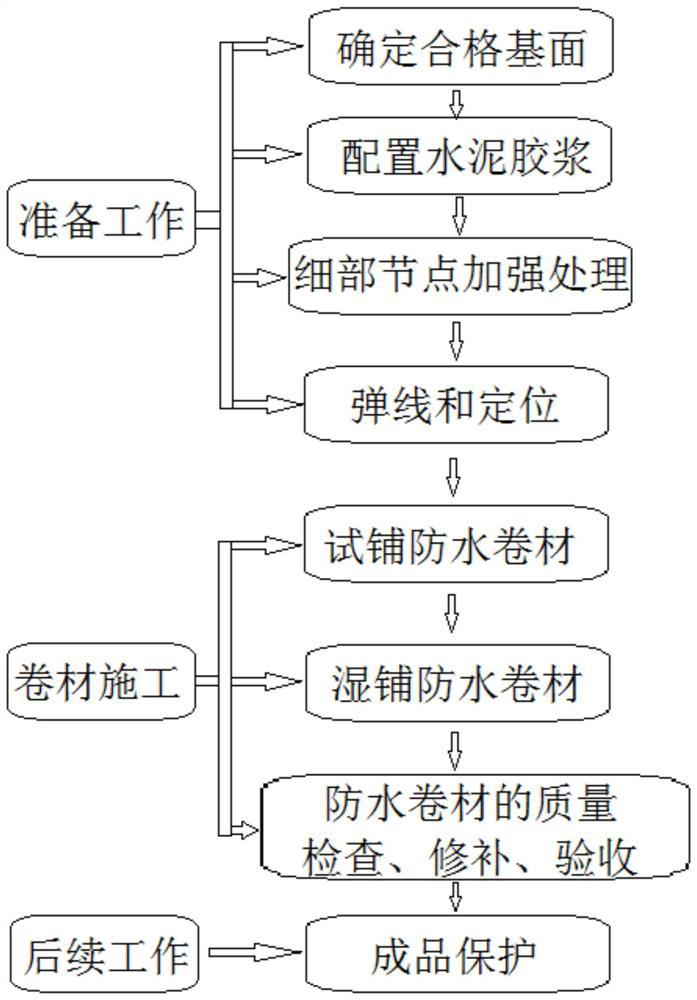

[0042] Such as figure 1 Shown, a kind of basement floor, exterior wall waterproof construction method, comprises the following steps,

[0043] Step 1: Preparatory work. The preparatory work includes selecting and determining a qualified base surface as a waterproof base, configuring cement mortar, strengthening treatment of detail nodes, and snapping lines and positioning;

[0044] Step 2: Waterproofing membrane construction, including trial laying waterproofing membranes, wet laying waterproofing membranes and quality inspection, repair and acceptance of waterproofing membranes; said wet laying waterproofing membranes also includes laying flat surface waterproofing membranes and equal-span waterproofing membranes. Deformation seam waterproof membrane laying;

[0045] Wherein, the laying of the flat surface waterproof coiled material is laid by a coiled material laying machine, and the coiled material laying machine moves along the direction of laying, automatically releases ...

Embodiment 2

[0060] This embodiment provides a membrane waterproof construction method at the deformation joint.

[0061] In the process of large-scale waterproof construction, deformation joints often appear, and the following treatment methods are used for deformation joints on flat surfaces.

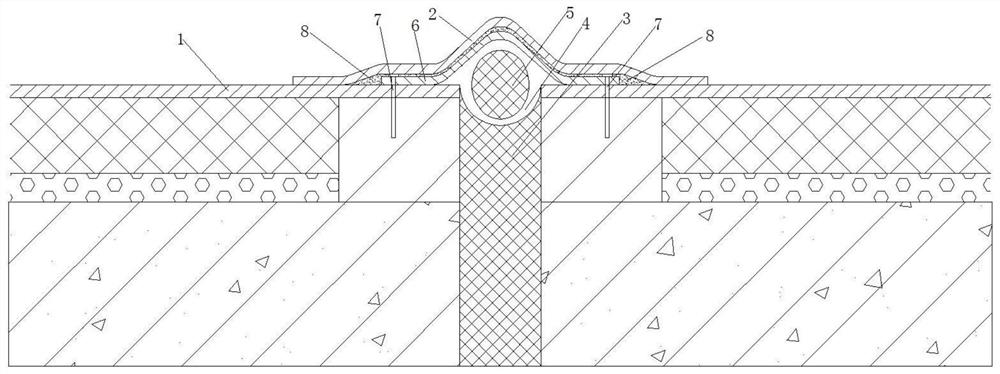

[0062] Such as figure 2As shown, one way of laying the equal-span deformation joint waterproof membrane is: fill the deformation joint with a caulking material 3, and the upper part of the caulking material 3 has a groove 4 and is provided with a foam rod 5. An additional layer of waterproof coiled material 6 is arranged above the foam rod 5, and the additional layer of waterproof coiled material 6 extends symmetrically to both sides and is fixed by closing beading and closing screws 7, and above the additional layer of waterproof coiled material 6 is laid the The waterproof roll material 2 also covers the entire additional layer 6 of the waterproof roll material; the gap between the waterproof ...

Embodiment 3

[0066] This embodiment provides another waterproof construction method of the coiled material at the deformation joint.

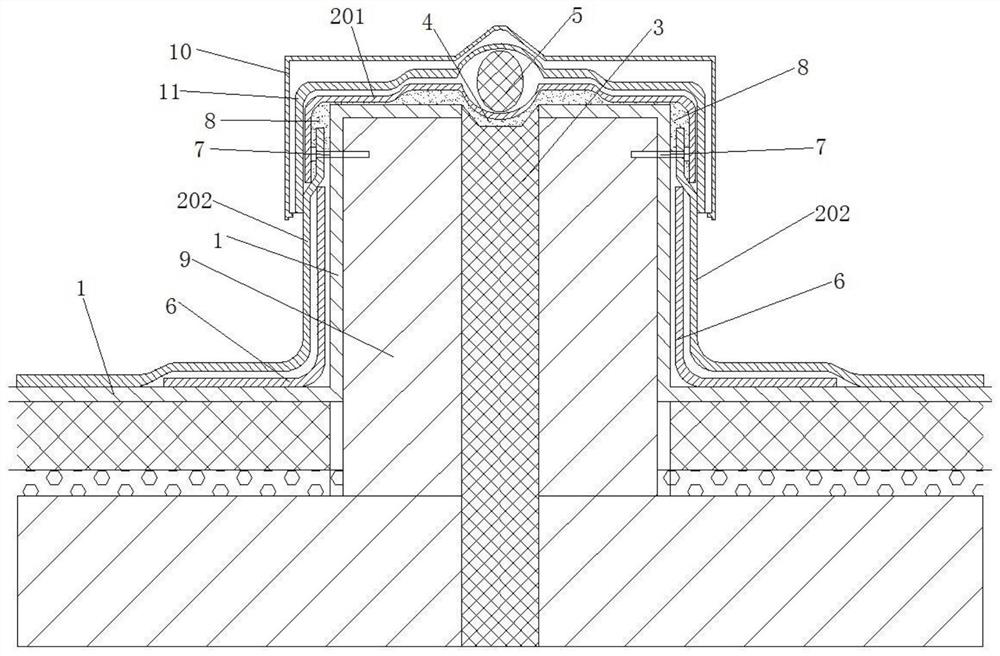

[0067] Such as image 3 As shown, another way of laying the equal-span deformation seam waterproof membrane is: the deformation seam is located in the raised structure 9, the caulking material 3 is filled in the deformation seam, and the upper part of the caulking material 3 is left There is a groove 4; a waterproof membrane-201 is laid on the raised structure 9; Connect waterproof roll material 2 202, said waterproof roll material 2 202 is fixed at the lap joint by closing bead and close screw 7; said waterproof roll material 2 202 is folded along the root corner of said protruding structure 9 and set there An additional layer 6 of waterproof roll material; the middle part of the waterproof roll material one 201 is sunken into the groove 4 and a foam rod 5 is arranged above, and a metal rainproof cover plate is also covered above the waterproof roll mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com