Hydrogen fuel cell vehicle maintenance and repair workshop and system and maintenance method thereof

A technology for fuel cells and maintenance workshops, which is applied to fuel cells, circuits, electrical components, etc., can solve problems such as hidden safety hazards, the system cannot work normally or efficiently, and no solutions are proposed, and achieve the effect of preventing the spread of explosive airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

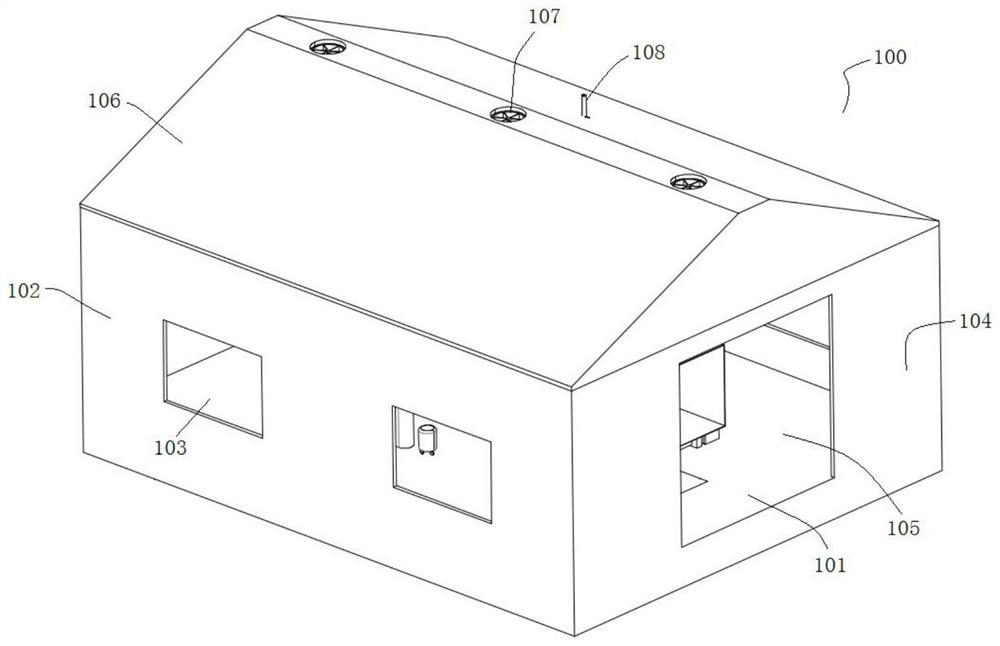

[0079] see figure 1 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the present embodiment provides a hydrogen fuel cell vehicle maintenance and repair workshop, which mainly includes: a workshop body 100 and a mobile leak detection device 300 and a hydrogen leakage device 400 arranged in the workshop body 100 And exhaust gas treatment device 500.

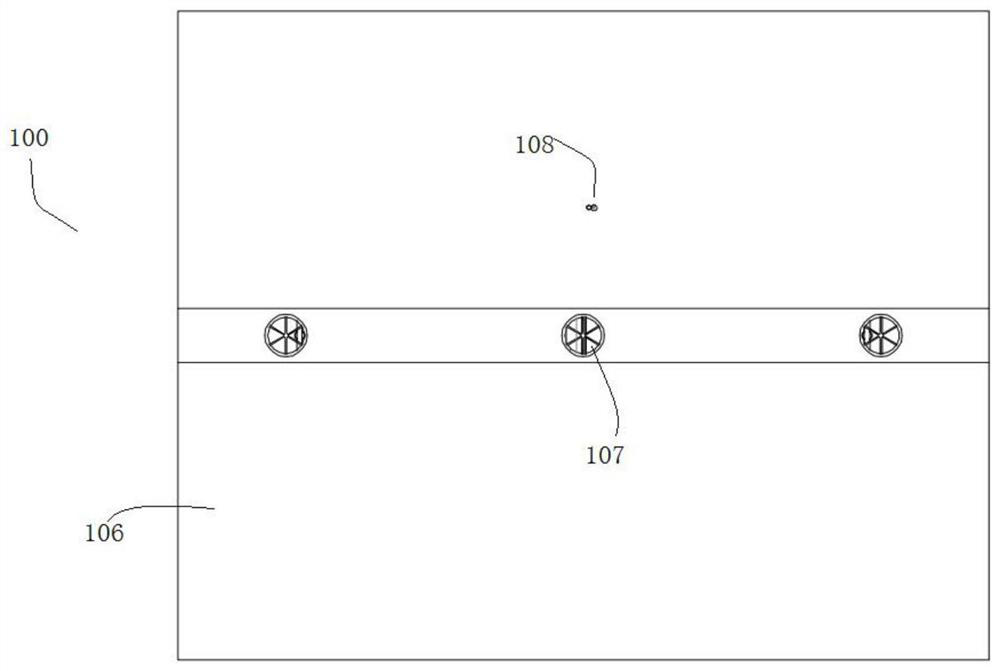

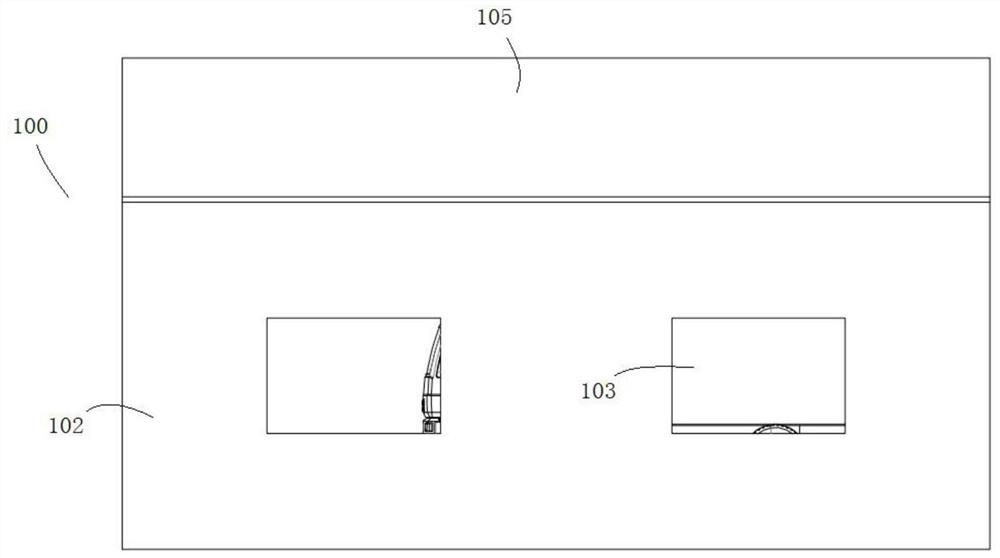

[0080] As a preferred technical solution of this embodiment, in order to prevent the workshop body 100 from collapsing due to the diffusion of explosive gas flow, and reduce property and personnel damage caused by the explosion. see figure 1 , figure 2 , image 3 and Figure 4 As shown, the workshop body 100 adopts a special structural design, which is composed of a foundation 101, three blast-proof walls 102, one blast-venting wall 104 and a ceiling 106, and three blast-proof walls 102 and one blast-proof wall 106. The explosion-proof wall 104 is sequentially connected to the wall structure surrounding the ...

Embodiment 2

[0095] read on Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, different from the above-mentioned Embodiment 1, this embodiment provides a hydrogen fuel cell vehicle maintenance and repair workshop, the hydrogen fuel cell vehicle maintenance and repair workshop not only includes a mobile leak detection device 300 located on one side of the maintenance pit 114 , the hydrogen release device 400 and the exhaust gas treatment device 500, and also include a maintenance toolbox 600 arranged on the same side and a charging pile 700 located on the other side of the maintenance pit 114, an antistatic device 800 and a vacuum cleaner 900 and other functional units. The units are arranged reasonably according to the needs.

[0096] As a preferred solution of this embodiment, please continue to refer to Figure 7 , Figure 9 and Figure 10 As shown, the maintenance tool box 600 is disposed in the workshop body 100 and is located on one side of the maintenance pit 114 for s...

Embodiment 3

[0101] read on Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, in the hydrogen fuel cell vehicle maintenance and repair workshop, the mobile leak detection device 300, the hydrogen release device 400, the exhaust gas treatment device 500 and the emergency exhaust device are special equipment developed; other equipment such as the maintenance tool box 600, the charging pile 700, the antistatic device 800 and the vacuum cleaner 900 are purchased equipment.

[0102] In this embodiment, the mobile leak detection device 300 used adopts a conventional gas leak detection device, an air-tight leak detector or other known leak detection equipment, etc., such as its structure including a helium cylinder, a pressure relief valve, a pressure relief valve, etc. Valves, flow meters, pressure gauges, on-off valves, pipelines and the main body of the leak detection device. The helium gas is installed on the main body of the leak detection device, and is detachably connected to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap