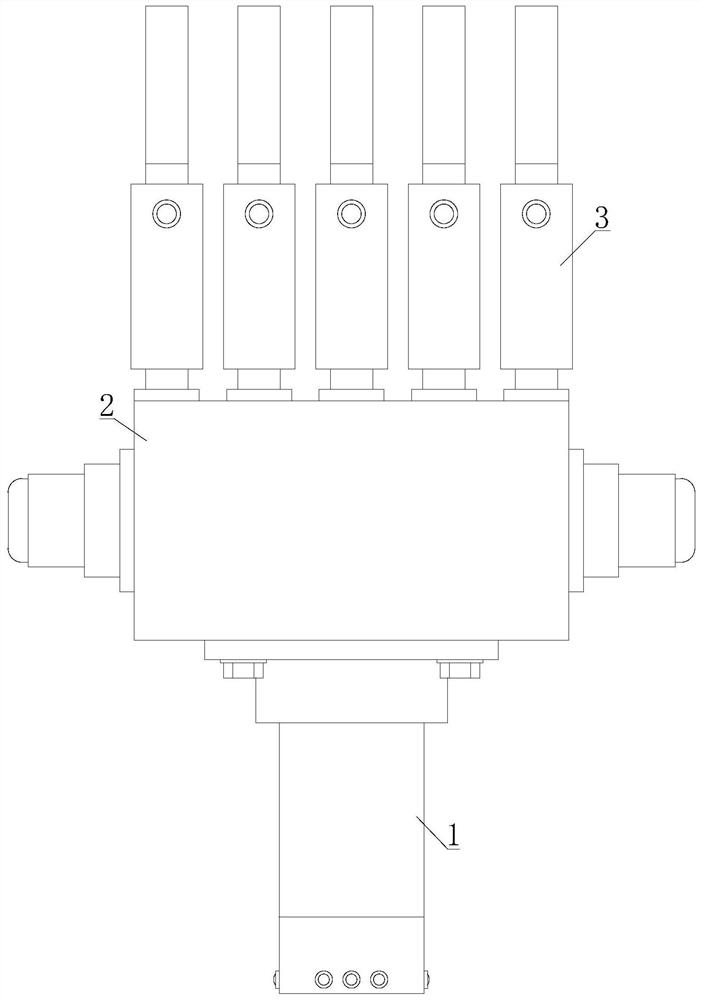

Decentralized cooling device for flue gas pipeline of bag type dust collector and implementation method of device

A bag-type dust collector and cooling device technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of scalding external operators, damage to external equipment, and lack of fast and effective flue gas cooling equipment, etc. Achieve the effect of preventing scalding of staff and rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] In order to better demonstrate the implementation process of the decentralized cooling device for the flue gas pipeline of the bag filter, this embodiment now proposes an implementation method for the decentralized cooling device for the flue gas pipeline of the bag filter, including the following steps:

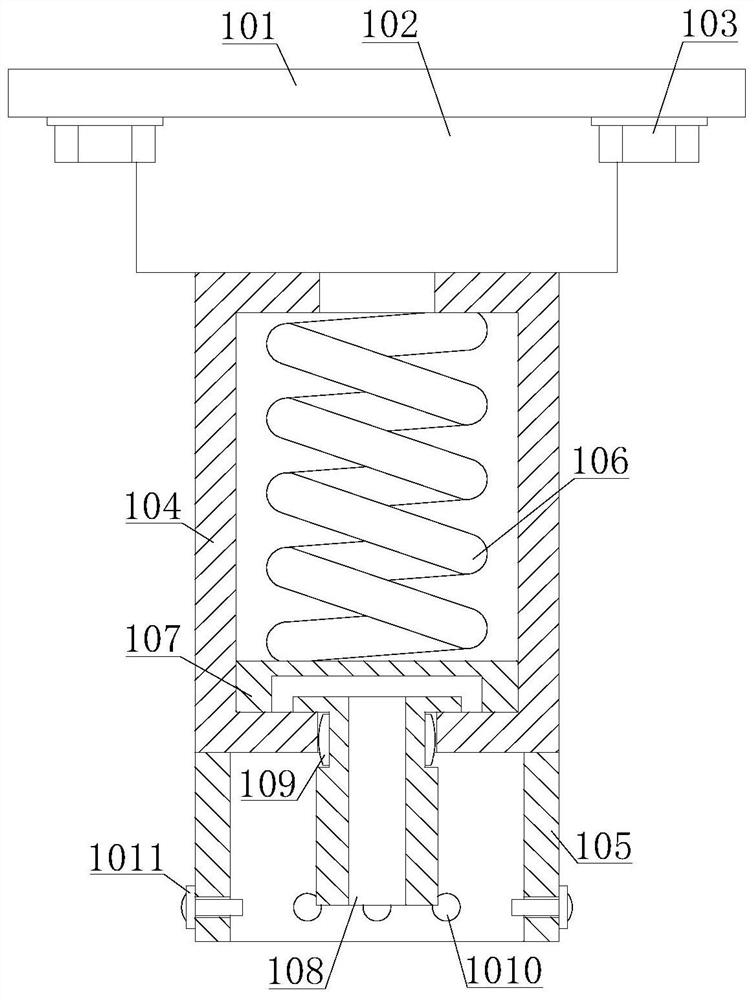

[0034] Step 1: Install the air pipe connection sleeve 105 of the connection port 1 at the flue gas outlet of the bag filter, and turn on the air extraction pump 27 in the flue gas delivery component 2 to extract air;

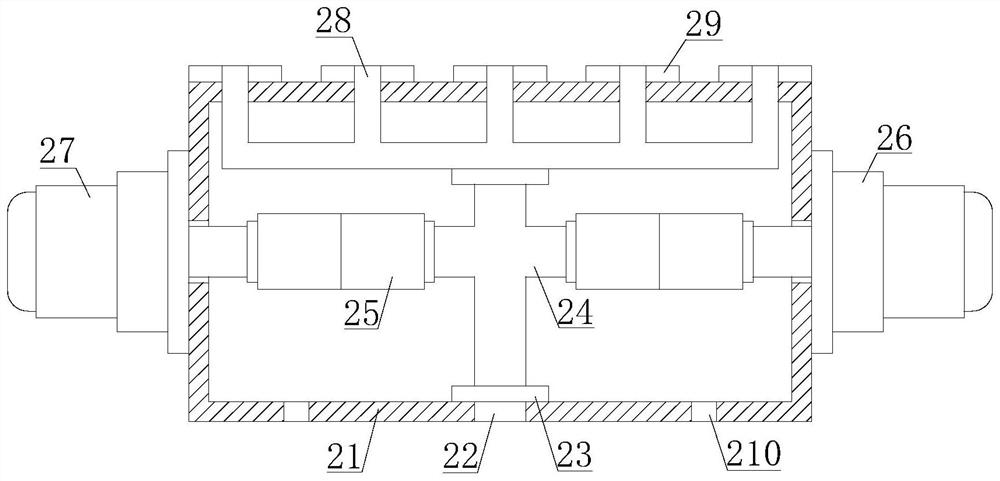

[0035] Step 2: The hot flue gas in the bag filter enters the gas delivery pipe 24 in the flue gas delivery assembly 2 through the connection port 1, and is transported upward to the dispersion pipe 28;

[0036] Step 3: The flue gas enters the air guide pipe 34 in the cooling unit 3 through the dispersion pipe 28, connects the threaded nozzle 33 with external circulating cooling water, and uses the cooling spiral pipe 37 to cool the air guide pipe 34;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com