Spraying coating drying device for home decoration

A drying device and paint technology, which is applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface, can solve the problems such as the influence of decoration efficiency, the effect of wall paint, and prolong the working time, etc. Drying efficiency and quality, meeting applicability and practicability, and preventing wall cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

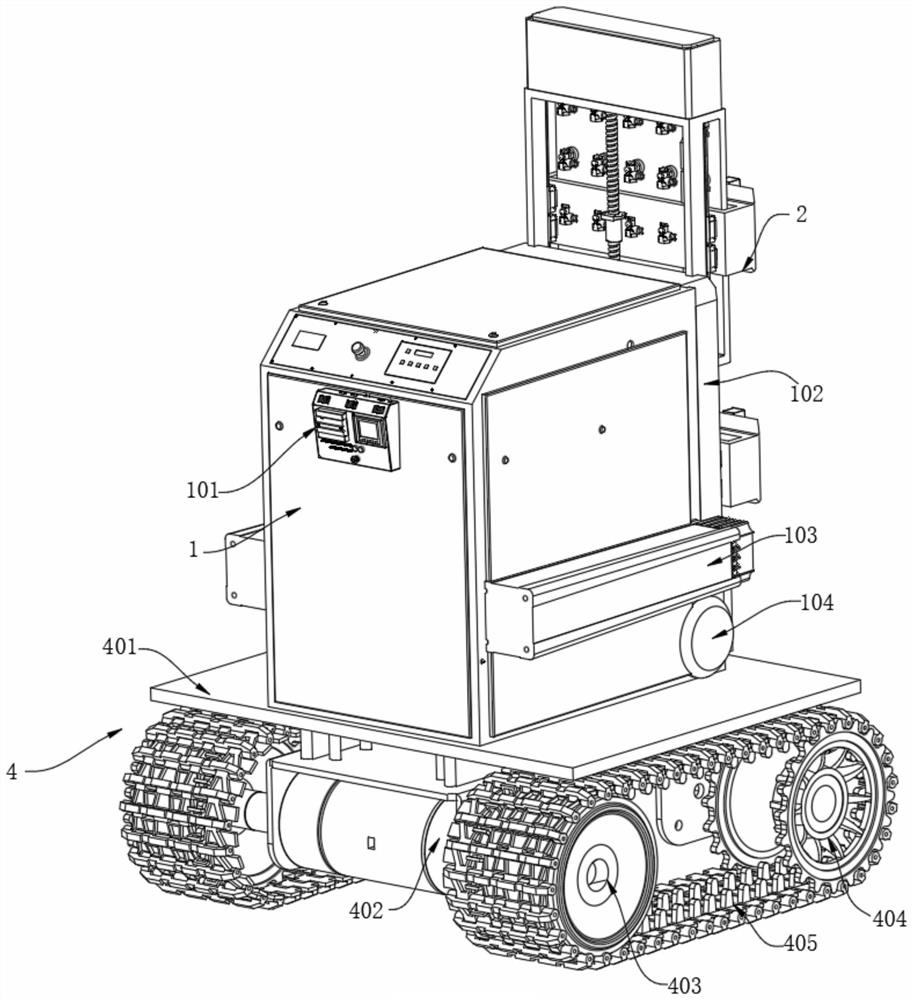

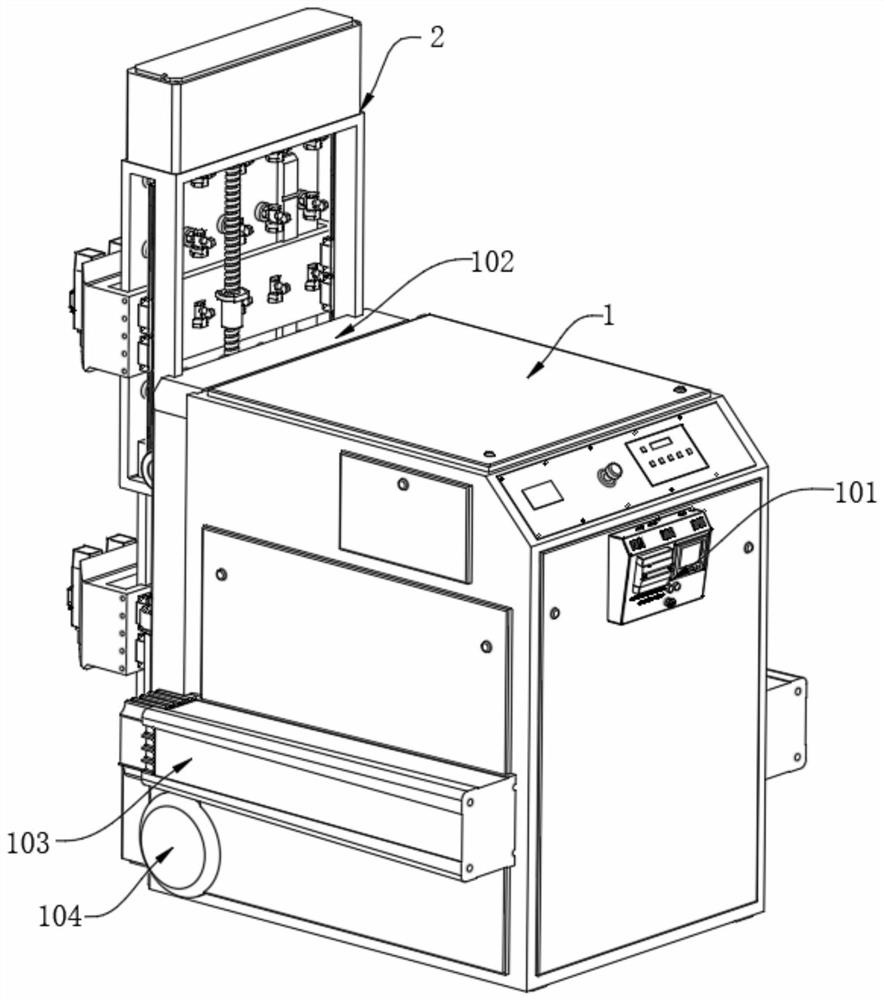

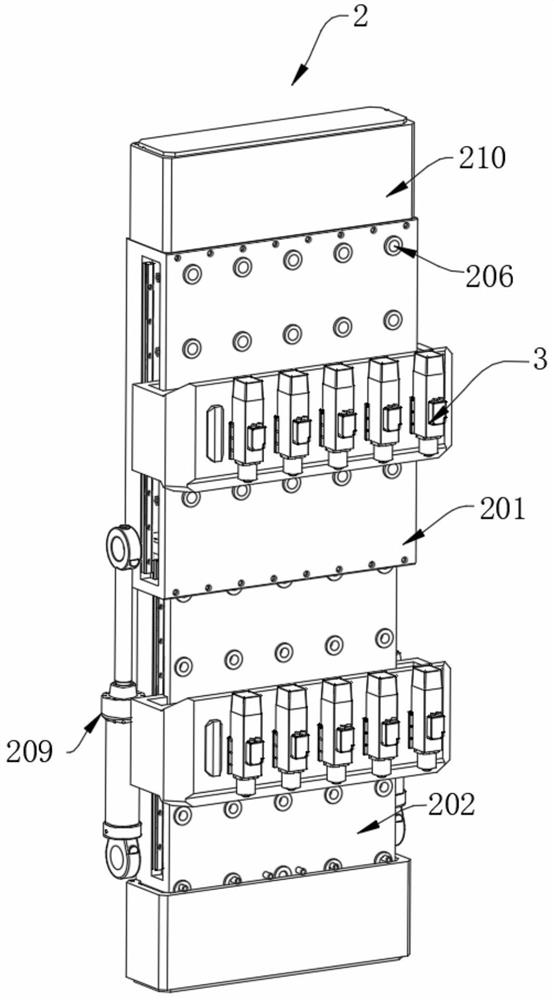

[0030] see Figure 1-8 , the present invention provides a technical solution: a spray paint drying device for home decoration, including a workbench 1, an adjustment mechanism 2, a drying mechanism 3 and a crawler mechanism 4, and the front surface of the workbench 1 is equipped with PLC control 101, the rear surface of the workbench 1 is welded with a base plate 102, the drying mechanism 3 includes a mobile support 301, a through groove 302, five connecting plates 304, a multi-cavity klystron 305 and a second position sensor 306, through The outer surface of the groove 302 is opened on the inner side wall of the mobile support 301, the connecting plate 304 is threadedly connected with the front surface of the mobile support 301 by screws, and the outer surface of the multi-chamber klystron 305 is welded to the outer surface of the connecting plate 304. The outer surface of the second position sensor 306 is installed on the front surface of the mobile support 301;

[0031] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com