Welding clamp of nuclear fuel assembly grillwork

A nuclear fuel assembly and welding fixture technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the internal stress of nuclear fuel assembly grid thermal deformation, reduce welding accuracy, nuclear fuel assembly grid service life, and prevent nuclear fuel Problems such as component grid cooling, to improve cooling efficiency and economy, prevent thermal deformation or excessive internal stress, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

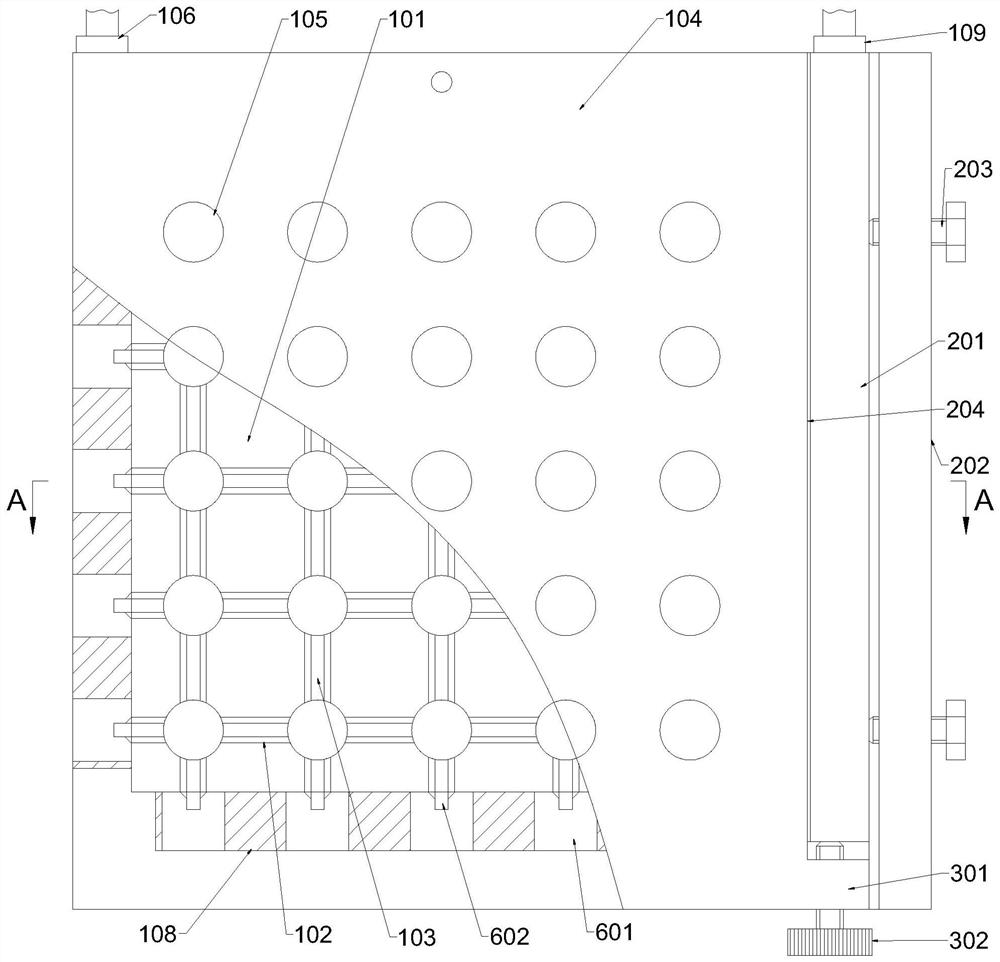

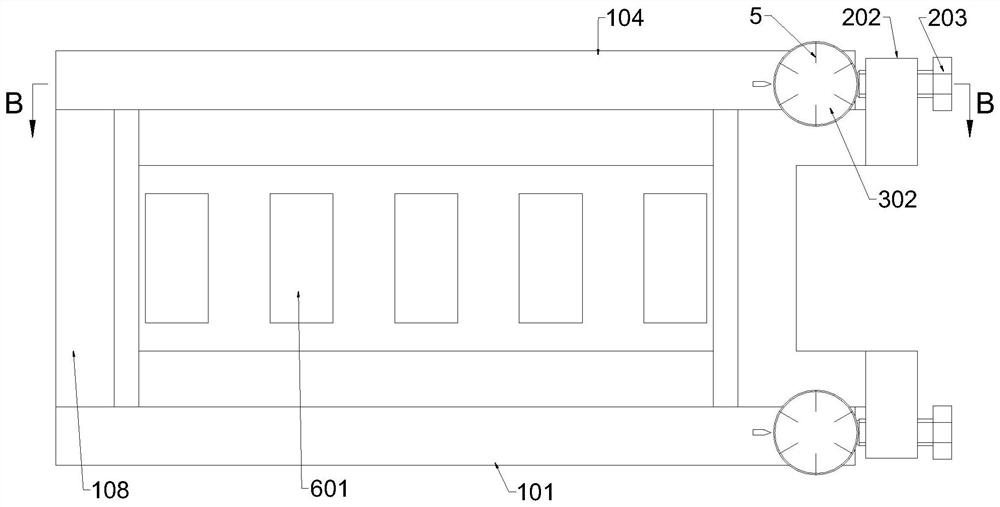

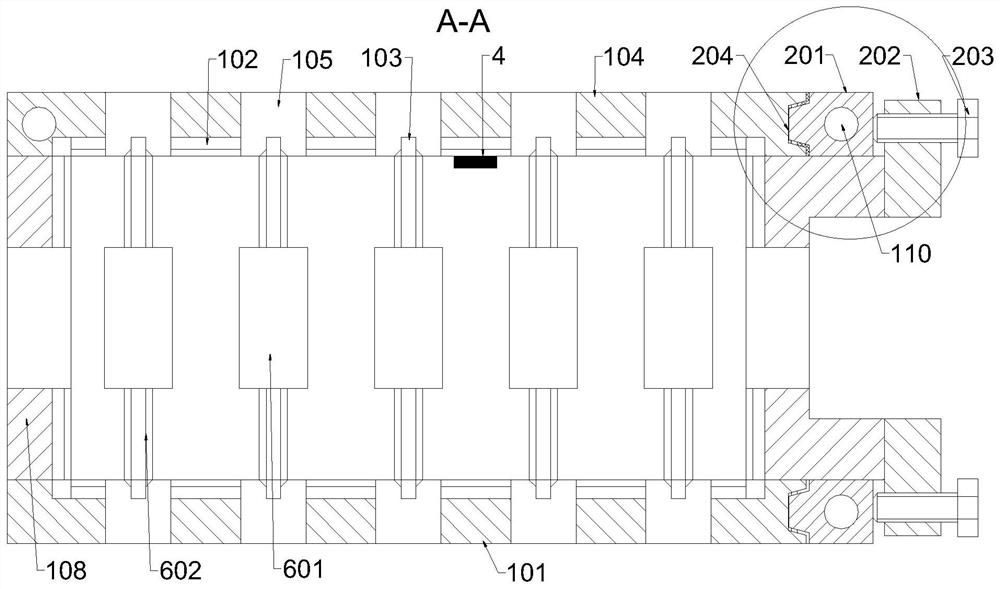

[0027] Such as Figure 1-4 As shown, a nuclear fuel assembly grid welding fixture provided by the present invention includes: a bottom plate 101, a cover plate 104, a side plate 108 interface mechanism and a liquid supply device, and the bottom plate 101 has a horizontal clamping groove 102 and a longitudinal clamping groove on the upper surface 103, the transverse slot 102 intersects with the longitudinal slot 103; the lower surface of the cover plate 104 is also provided with intersecting transverse slot 102 and longitudinal slot 103, and the cover plate 104 and the bottom plate 101 are both in the transverse slot 102 A welding hole 105 is also provided at the intersection with the longitudinal slot 103, and a liquid outlet 106 and a plurality of cooling holes 107 are provided in the cover plate 104 and the bottom plate 101, and the liquid outlet 106 communicates with the plurality of cooling holes 107; Side plate 108, one end is detachably connected to the bottom plate 101,...

Embodiment 2

[0032] On the basis of Embodiment 1, in order to be able to regulate the flow rate of the cooling liquid according to the temperature of the cover plate 104, and then keep the nuclear fuel assembly grid at an optimum temperature during welding, and improve cooling efficiency and economy.

[0033] Such as Figure 1-5 As shown, wherein, the interface mechanism includes a slide bar 201, a compression plate 202 and a compression bolt 203, and the side edge of the cover plate 104 and the bottom plate 101 is provided with a trapezoidal groove 204, and a plurality of cooling holes 107 are all connected to the trapezoidal At the bottom of the groove 204, one side of the slide bar 201 is sealed and slidably connected with the trapezoidal groove 204, and the pressing plate 202 is fixedly connected to the outer wall of the side plate 108, and the pressing plate 202 is provided with a first screw thread hole, the compression bolt 203 is connected with the first threaded hole, one end of t...

Embodiment 3

[0037] On the basis of Embodiment 2, in order to be able to monitor the temperature of the nuclear fuel assembly grid in real time, and then control the temperature of the nuclear fuel assembly grid more accurately.

[0038] Such as image 3 As shown, it also includes a temperature sensor 4, the temperature sensor 4 is fixedly connected to the lower surface of the cover plate 104, the temperature sensor 4 is electrically connected to a controller, and the controller is electrically connected to a display and a power supply device. The temperature sensor 4 detects the temperature of the cover plate 104 in real time and transmits the temperature signal to the controller, and the controller controls the display to display the real-time temperature value of the cover plate 104 .

[0039] Real-time monitoring of the temperature value of the cover plate 104 by the temperature sensor 4, thereby indirectly knowing the real-time temperature value of the nuclear fuel assembly grid, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com