Line polishing machine used for wire-drawing die

A wire drawing die and polishing machine technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of low motion accuracy and machining accuracy, cumbersome and time-consuming adjustment, and easy wire breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

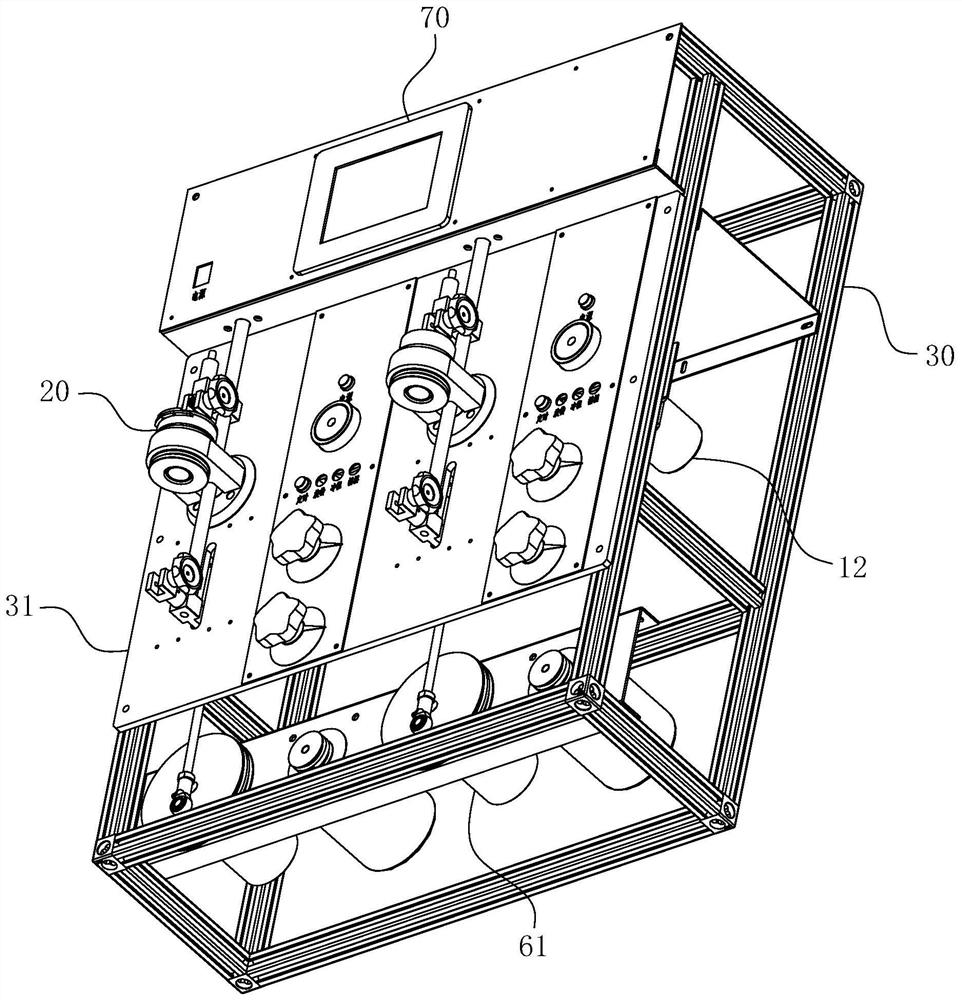

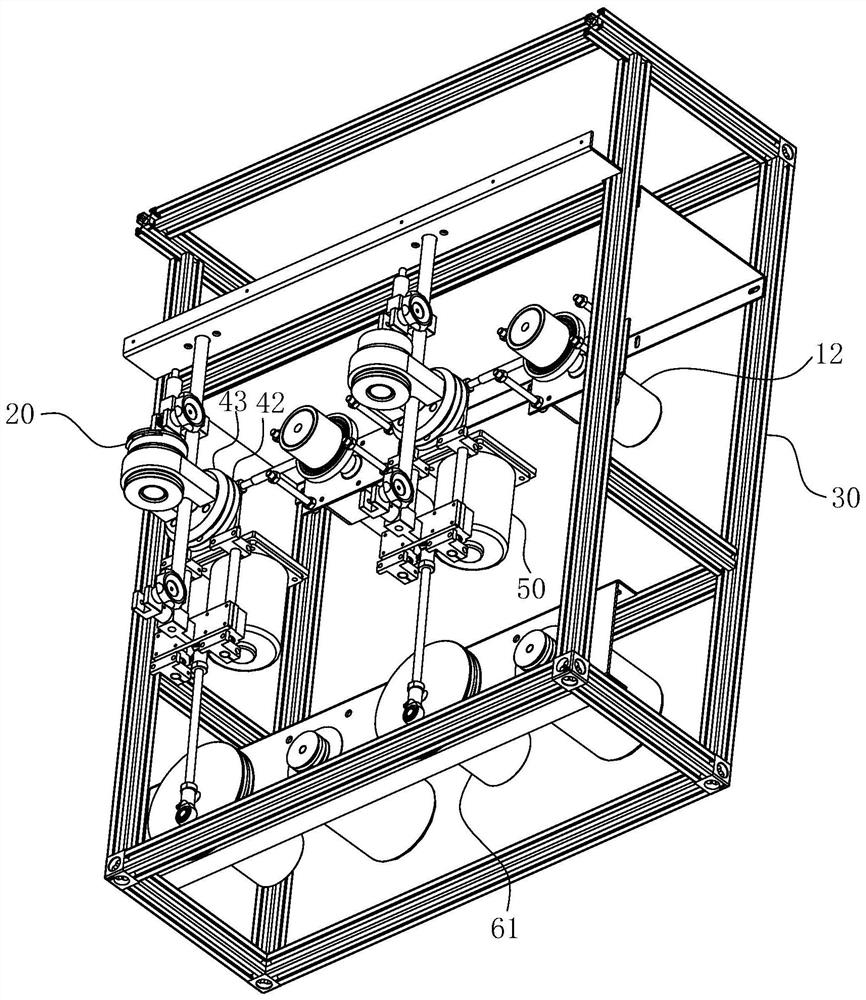

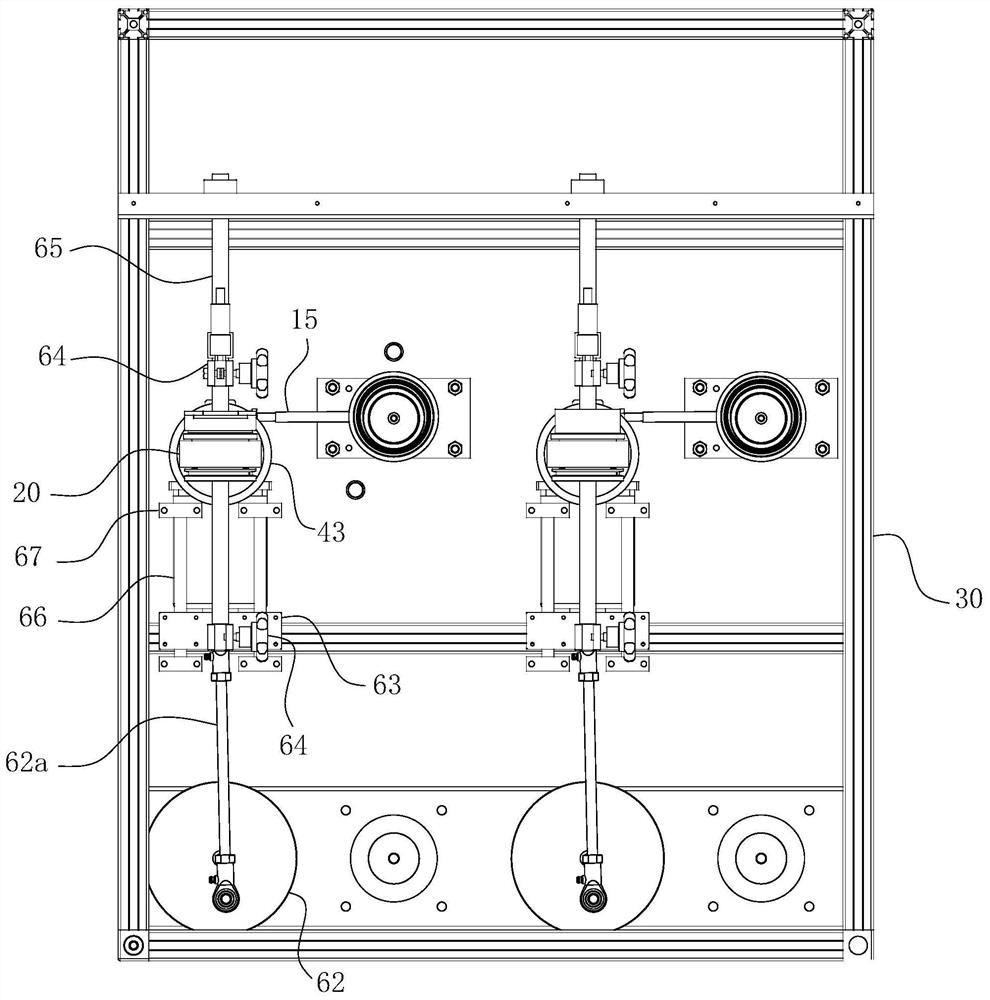

[0057] For ease of understanding, combined here Figure 1-15 , the concrete structure and working mode of the present invention are further described as follows:

[0058] The concrete implementation structure of the present invention refers to Figure 1-15 As shown, it uses the frame 30 as a carrier, and at least a rotary drive module and a yaw adjustment module are arranged on the frame 30 and the panel 31 of the frame 30, so that when the rotary drive module is used to rotate and position the mold base 20, the Turning action, in order to use the tool wire to polish the inner hole of the drawing die a located in the positioning die base 20, and then use the continuous gradual angle adjustment effect of the yaw adjustment module to achieve reliable and continuous adjustment of the inner hole The deflection polishing purpose. Of course, in practice, you can also Figure 1-4 The further addition of the axial drive module shown, that is, another process is integrated, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com