A kind of photoelectric glass with film circuit and production process

A photoelectric glass and production process technology, applied in glass/slag layered products, light sources, layered products, etc., can solve the problems of weakening lamp brightness, circuit damage, affecting visual effects, etc., to improve product yield, increase Service life, increase the effect of visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

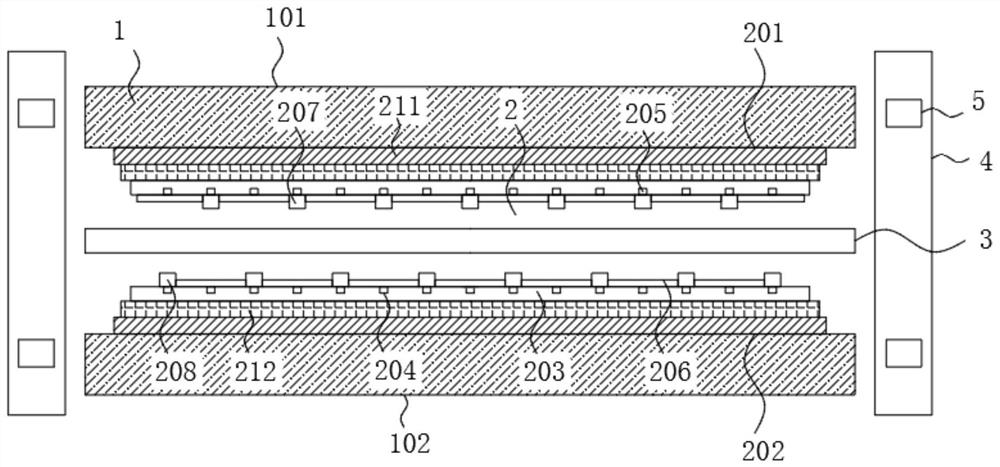

[0038] The invention provides a kind of photoelectric glass with a film line, such as Figure 1-3As shown, the photoelectric layer 2 is located inside the glass layer 1. By encapsulating the photoelectric glass with a film circuit, it is beneficial to encapsulate the photoelectric glass according to the ultra-thin and high transparency effect of the film circuit. The packaging process is relatively simple, which solves the traditional low-efficiency process methods such as direct laser engraving or printing on glass, saves costs, reduces energy consumption in the production process, improves product yield, and is not easy to damage the film line, and the finished product has a good visual effect;

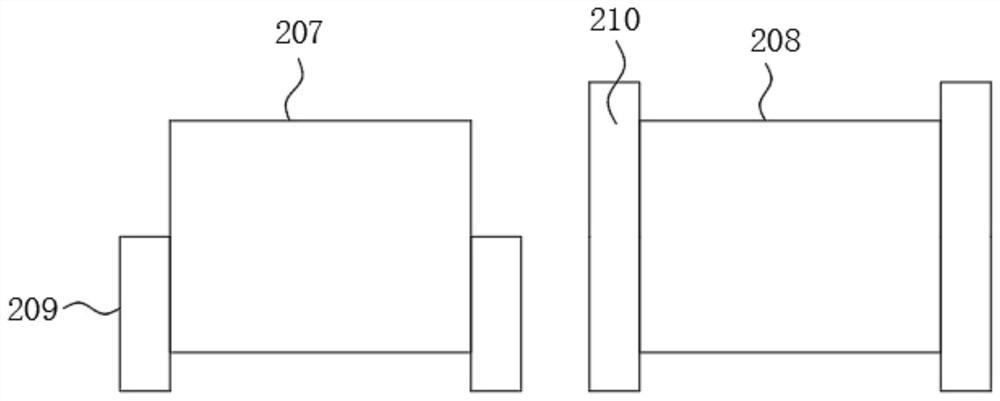

[0039] The glass layer 1 includes an upper glass layer 101 and a lower glass layer 102, the photoelectric layer 2 includes a first conductive layer 201 and a second conductive layer 202, and the first conductive layer 201 is fixedly connected to the upper surface of the lower glass l...

Embodiment 2

[0042] The invention provides a kind of photoelectric glass with a film line, such as Figure 1-3 As shown, the photoelectric layer 2 is located inside the glass layer 1. By encapsulating the photoelectric glass with a film circuit, it is beneficial to encapsulate the photoelectric glass according to the ultra-thin and high transparency effect of the film circuit. The packaging process is relatively simple, which solves the traditional low-efficiency process methods such as direct laser engraving or printing on glass, saves costs, reduces energy consumption in the production process, improves product yield, and is not easy to damage the film line, and the finished product has a good visual effect;

[0043] The glass layer 1 includes an upper glass layer 101 and a lower glass layer 102, the photoelectric layer 2 includes a first conductive layer 201 and a second conductive layer 202, and the first conductive layer 201 is fixedly connected to the upper surface of the lower glass ...

Embodiment 3

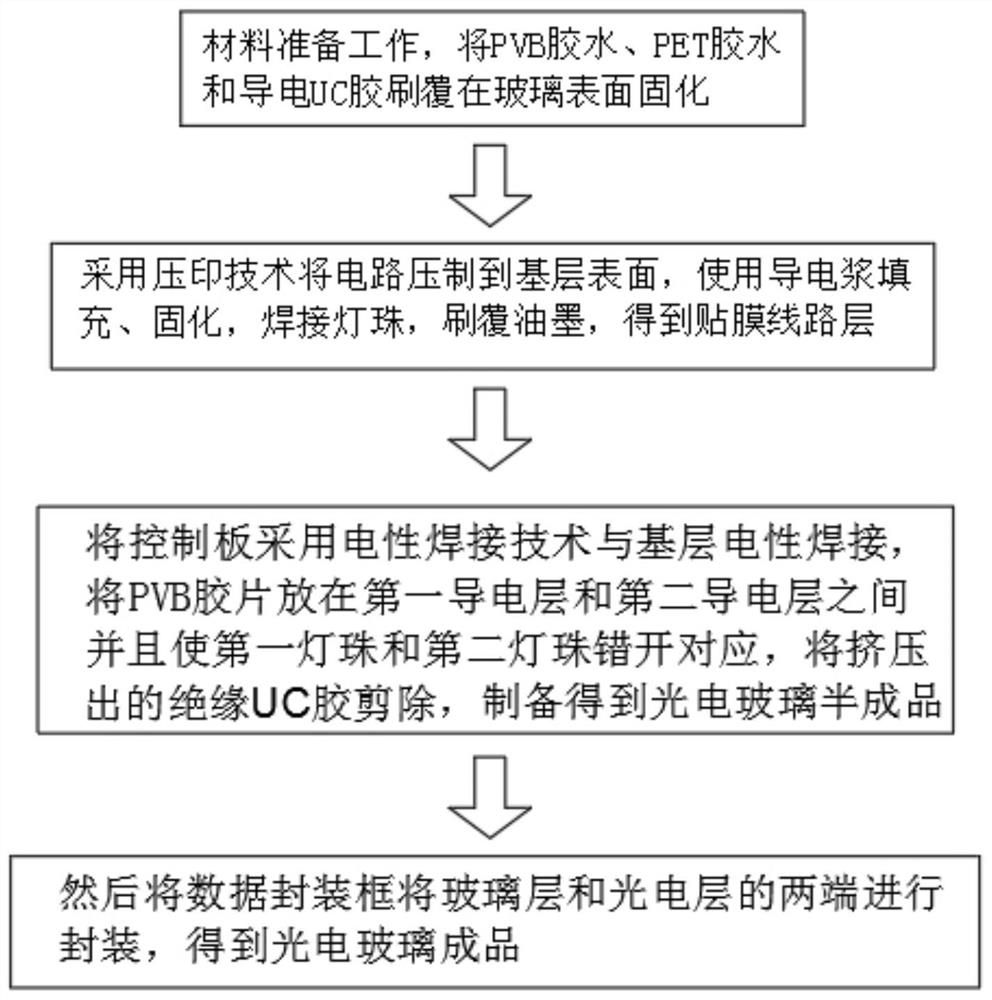

[0046] The invention also discloses a production process of photoelectric glass with a film-attached circuit, which includes the following steps:

[0047] S1: First, brush PVB glue and PET glue on the surface of the upper glass layer 101 and the lower glass layer 102 to form a transparent PVB glue layer 212 and a transparent PET layer 211, and then coat a layer of conductive UC glue on the surface of the transparent PET layer 211 and solidify Form the base layer 203 with high flatness, then engrave the circuit diagram to be embossed on the surface of the mold, and make the engraved circuit diagram appear as a raised display, and then emboss on the surface of the base layer 203 to emboss the circuit pattern to form an embossing groove 204, filling the prepared conductive paste into the circuit pattern in the embossing groove 204, scraping off the excess conductive paste, and drying to form the circuit layer 205;

[0048] S2: Solder the first soldering layer 209 of the first lam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com