Demolding breathable felt as well as preparation method and application thereof

A breathable felt and mold release technology, which is applied in textiles and papermaking, non-woven fabrics, fabric surface trimming, etc. Efficiency of use and the effect of preventing glue spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

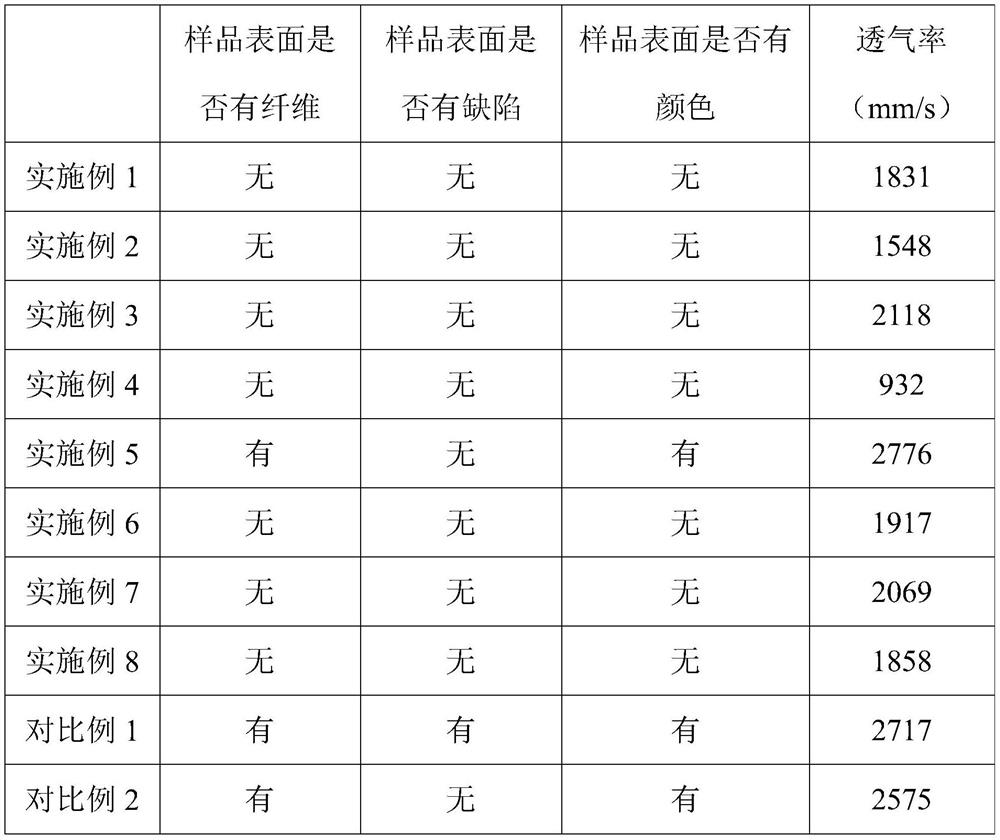

Examples

Embodiment 1

[0044] A method for preparing a release air felt, specifically comprising the steps of:

[0045] (1) the length is 60mm, the linear density is 4D, and the polypropylene fiber prepared by the melt spinning method is opened through an opener with a rotating speed of 80rpm to obtain bundled fibers;

[0046] (2) the bundle fiber that step (1) obtains is combed through the breast cylinder that frequency is 40Hz, the middle doffer that frequency is 20Hz, the main cylinder that frequency is 40Hz and the rear doffer that frequency is 20Hz, obtains reticular fiber;

[0047] (3) The mesh fiber obtained in step (2) is passed through a pre-punching machine with a frequency of 27 Hz, a first upper needle machine with a frequency of 33 Hz, a first lower needle machine with a frequency of 33 Hz, and a second needle machine with a frequency of 23 Hz. The upper needling machine and the second lower needling machine with a frequency of 23 Hz are processed to obtain the initial air felt;

[004...

Embodiment 2

[0050] A method for preparing a release air felt, specifically comprising the steps of:

[0051] (1) the length is 51mm, the linear density is 2.5D, and the polypropylene fiber prepared by the melt spinning method is opened by an opener with a rotating speed of 70rpm to obtain bundled fibers;

[0052] (2) the bundle fiber that step (1) obtains is combed through the breast cylinder that frequency is 35Hz, the middle doffer that frequency is 15Hz, the main cylinder that frequency is 35Hz and the rear doffer that frequency is 15Hz, obtains reticular fiber;

[0053] (3) The mesh fiber obtained in step (2) is passed through a pre-punching machine with a frequency of 25 Hz, a first upper needle machine with a frequency of 30 Hz, a first lower needle machine with a frequency of 30 Hz, and a second needle machine with a frequency of 20 Hz. The upper needling machine and the second lower needling machine with a frequency of 20 Hz are processed to obtain the initial air felt;

[0054] ...

Embodiment 3

[0056] A method for preparing a release air felt, specifically comprising the steps of:

[0057] (1) the length is 76mm, the linear density is 6D, and the polypropylene fiber prepared by the melt spinning method is opened by an opener with a rotating speed of 100rpm to obtain bundled fibers;

[0058] (2) the bundle fiber that step (1) obtains is combed through the breast cylinder that frequency is 50Hz, the middle doffer that frequency is 35Hz, the main cylinder that frequency is 50Hz and the rear doffer that frequency is 35Hz, obtains reticular fiber;

[0059] (3) The reticular fiber obtained in step (2) is passed through a pre-punching machine with a frequency of 30 Hz, a first upper needle machine with a frequency of 35 Hz, a first lower needle machine with a frequency of 35 Hz, and a second needle machine with a frequency of 25 Hz. The upper needling machine and the second lower needling machine with a frequency of 25 Hz are processed to obtain the initial air felt;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com