Ultrafine tungsten filament rope as well as preparation method and application thereof

A tungsten wire rope and ultra-fine technology, which is applied in the field of tungsten wire rope, can solve the problems that the production bottleneck of fine tungsten wire rope cannot be broken through, the industry requirements cannot be met, and the repeating position accuracy is low, so as to achieve breakthrough in production bottleneck, uniform force, The effect of filling the gap in the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

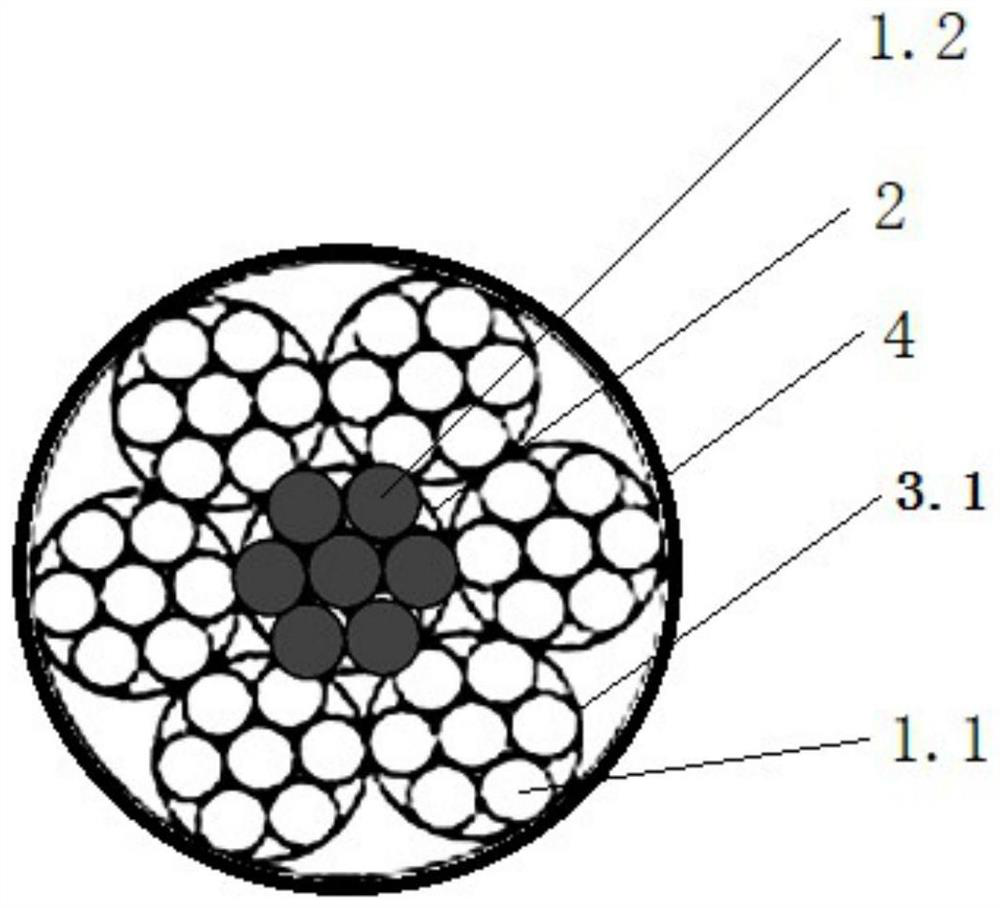

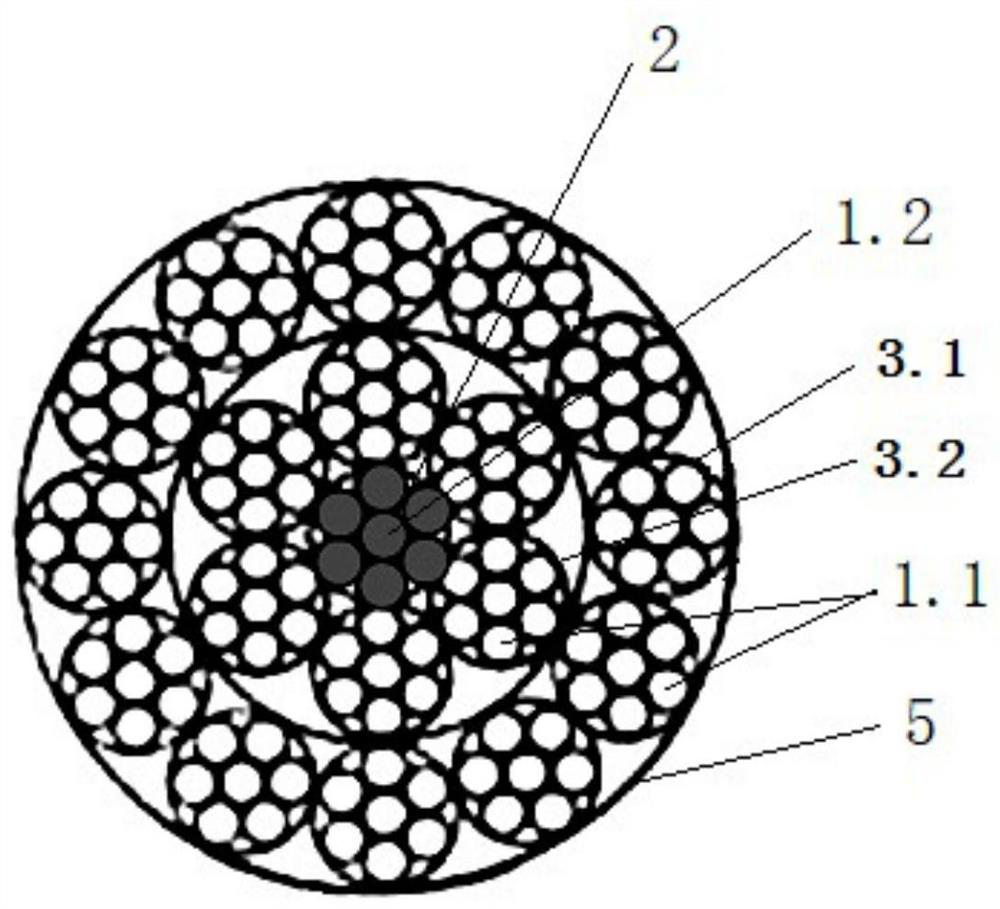

[0027] Such as figure 1 , figure 2 As shown, the present invention provides an ultra-fine tungsten wire rope, including a central strand 2 and an outsourcing strand, the outsourcing strand comprising, a pre-deformed first outsourcing strand 3.1 having a helical structure and a torque, and the original wire being directly wound the second outsourcing strand 3.2; a number of the first outsourcing strands 3.1, or a number of the first outsourcing strands 3.1 and a number of the second outsourcing strands 3.2 twisted on the periphery of the central strand 2 to form a tungsten wire rope.

[0028] Based on the above embodiment, the central strand 2 is wound by seven central filaments 1.2; the diameter of the central strand 2 is 0.083-0.135 mm.

[0029] In the present invention, the first outsourcing strand 3.1 is pre-deformed before winding to form a helical structure pre-deformed outsourcing strand with a pitch of 2.88-3.25mm, which realizes the pre-twisting function and can bet...

Embodiment 2

[0039] A method for preparing an ultra-fine tungsten wire rope, comprising: 1), winding several raw wires into central strands 2 or outsourcing strands;

[0040] 2) Pre-deform the first outsourcing strand 3.1 in the outsourcing strand in advance to form a pre-deformed outsourcing strand with a helical structure and torque; 3), wind several first outsourcing strands 3.1 around the central strand 2 around the central strand 2 to form a tungsten wire rope; or the second outsourcing strand 3.2 is wound around the center strand 2 around the center strand 2 to form an outsourcing strand layer, and finally the outsourcing strand layer is surrounded by a pre-deformed first outsourcing strand Strand 3.1, forming a tungsten wire rope.

[0041] Further, in step 3), the periphery of the center strand 2 is provided with several layers of outsourcing strand layers, and the first outsourcing strand 3.1 and the second outsourcing strand 3.2 on the periphery of the center strand 2 can be alter...

Embodiment 3

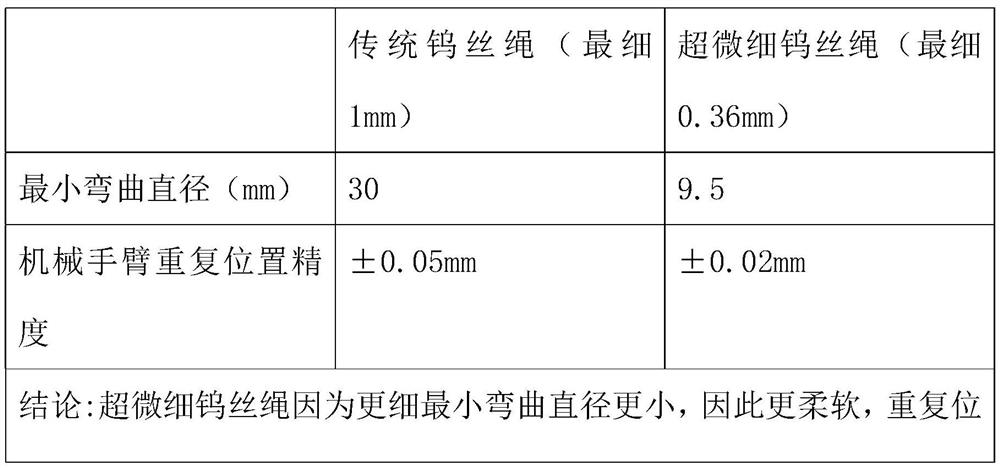

[0048] An application of the ultra-fine tungsten wire rope in the transmission control of the high-precision and high-tension precision robot arm of medical equipment. Because the tungsten wire rope has the characteristics of corrosion resistance and high temperature resistance, the service life of the robot arm transmission is improved; more importantly, through the preparation method of the ultrafine tungsten wire rope provided by the present invention, the ultrafine tungsten wire rope (rope Diameter: 0.36mm), the diameter of the ultra-fine tungsten wire rope is much smaller than that of the traditional steel wire rope (diameter>1mm), and the ultra-fine tungsten wire rope is softer because of its thinner minimum bending diameter, and the repeat position accuracy is higher High, can meet the precision requirements of precision robot arm transmission control, and the tensile force and flexibility of ultra-fine tungsten wire rope are far higher than the performance of traditiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com