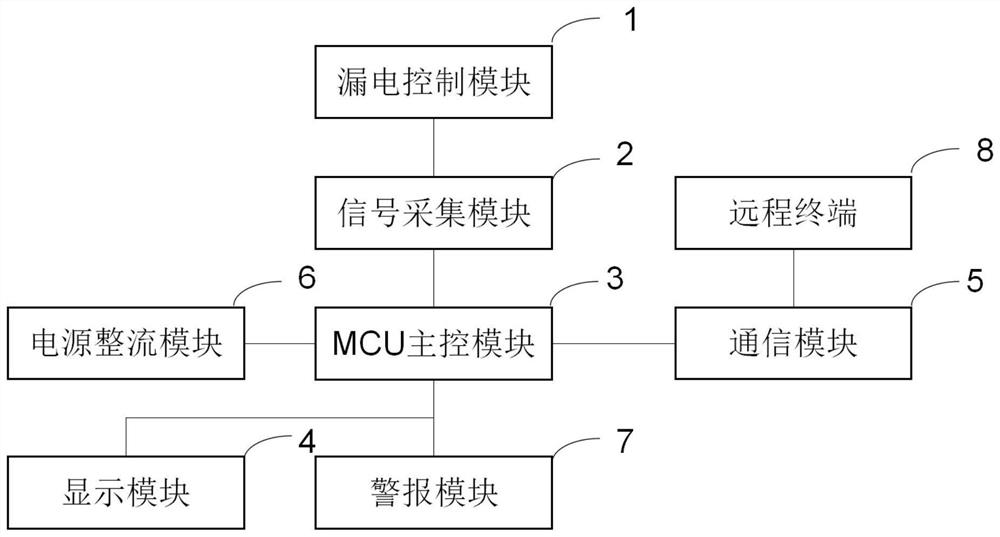

Electricity utilization safety monitoring system and method

A technology of safety monitoring and leakage current, applied in information technology support system, short-circuit test, electrical components, etc., can solve the problems of complex electric field distribution, geometric area and distance of immersed parts of electrical appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

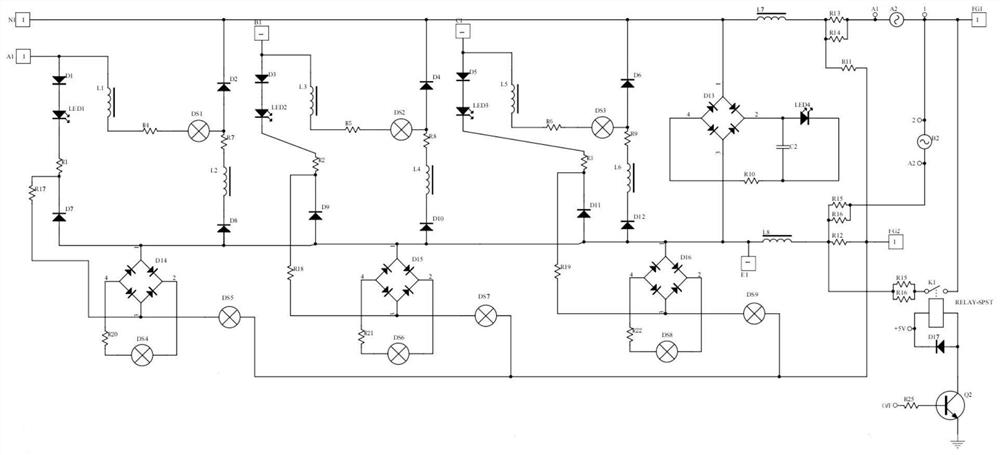

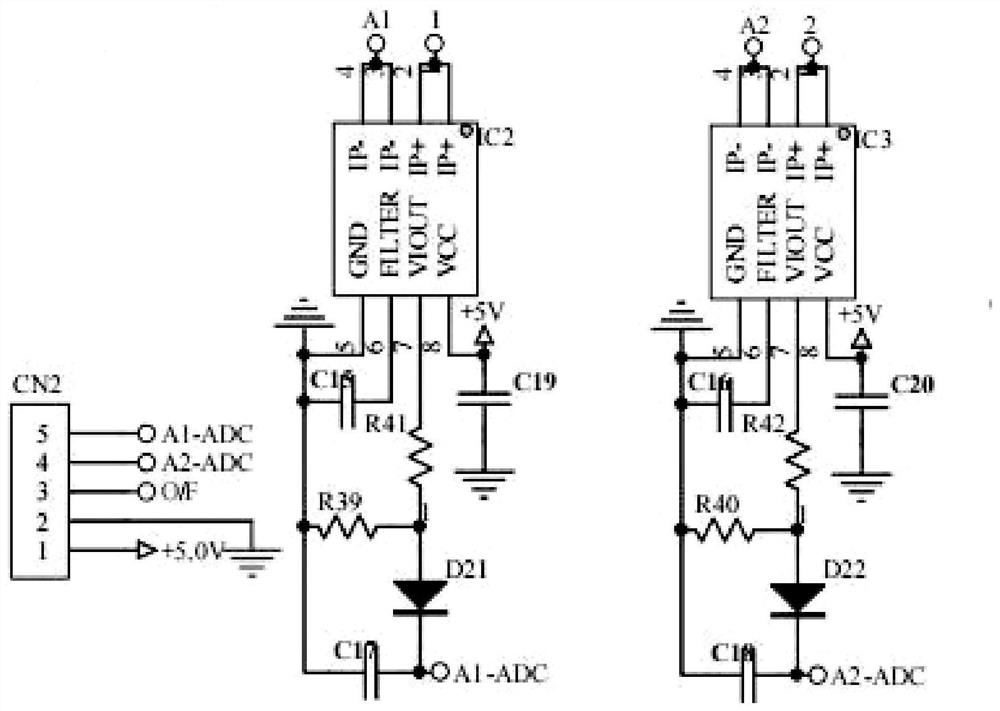

[0076]When the leakage control module 1 is connected to a three-phase four-wire three-phase power supply, the terminals A1, B1, C1 and N1 of the leakage control module 1 are connected in parallel to the live wires A, B, C and neutral wires of the three-phase power supply in sequence. N. Generally, the three-phase power supply equipment needs a grounding wire when it is connected to electricity, and the grounding wire is generally connected to the shell of the equipment. In this device, the other end of the grounding wire can be connected to the equipment grounding terminal FG1; the grounding terminal E1 in the leakage control module 1 The floating ground terminal FG2 can be selected according to the actual situation. Under normal circumstances, the ground terminal E1 is selected, and the ground terminal E1 is directly buried in the ground to facilitate drainage to the ground.

[0077] When the system is in normal use, the terminals A1, B1, and C1 of the leakage control module ...

Embodiment 2

[0079] When the leakage control module 1 is connected to the two-phase power supply, the terminals A1 and N1 of the leakage control module 1 are sequentially connected in parallel to the live line L and the neutral line N of the two-phase power supply. Generally, high-power equipment needs a grounding wire when it is connected to electricity, and the grounding wire is generally connected to the shell of the equipment. In this device, the other end of the grounding wire can be connected to the equipment grounding terminal FG1; the grounding terminal E1 in the leakage control module 1 The floating ground terminal FG2 can be selected according to the actual situation. Under normal circumstances, the ground terminal E1 is selected, and the ground terminal E1 is directly buried in the ground to facilitate drainage to the ground.

[0080] When the system is in normal use, the terminals A1 and N1 of the leakage control module 1 will rectify and discharge the two-phase current through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com