Shell assembly, preparation method thereof and electronic equipment

A shell assembly and shell technology, which is applied in the electronic field, can solve the problems of high processing cost, limited application, and harsh processing conditions, and achieve the effects of light weight, avoiding homogeneity, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

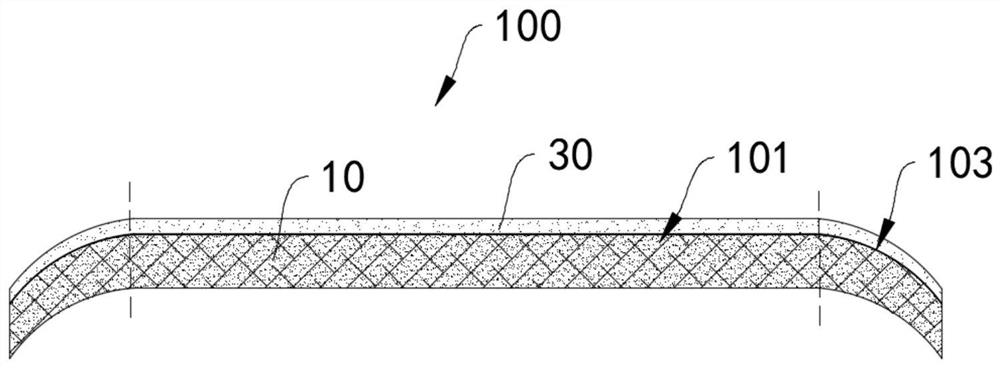

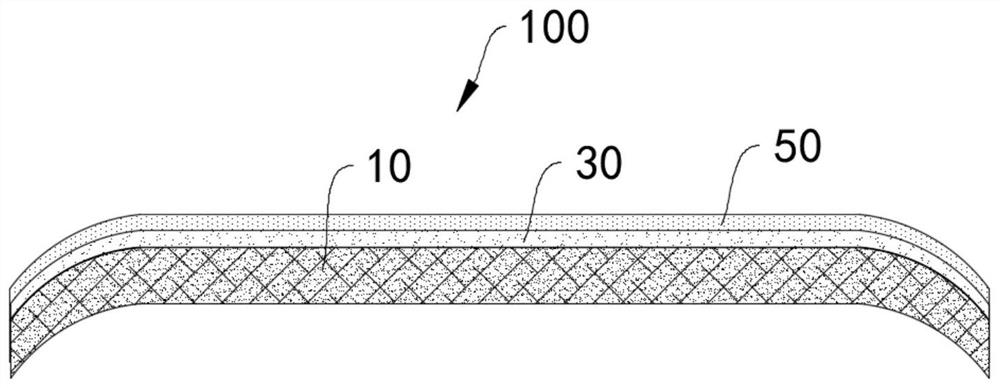

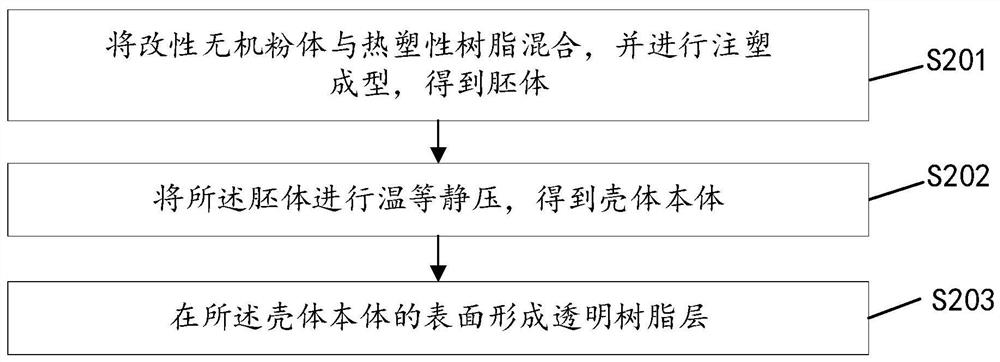

[0066] Please also see figure 1 and image 3 , the embodiment of the present application also provides a method for manufacturing the housing assembly 100, and the manufacturing method for the housing assembly 100 can be applied to manufacturing the housing assembly 100 of the above-mentioned embodiment. The housing assembly 100 includes a housing body 10 and a transparent resin layer 30, the transparent resin layer 30 is disposed on the surface of the housing, and the manufacturing method of the housing assembly 100 includes:

[0067] S201, mixing the modified inorganic powder with a thermoplastic resin, and performing injection molding to obtain an embryo body.

[0068] Optionally, the mixing may adopt, but is not limited to, one or more of dry mixing and wet mixing. The term "dry mixing" in the present application refers to a method in which solid components are mixed by, for example, ball milling, sand milling, mechanical blending and the like. The term "wet mixing" in ...

Embodiment 1

[0129] The housing assembly 100 of this embodiment is manufactured through the following steps:

[0130] 1) Weighing modified alumina and polyphenylene sulfide with a weight ratio of 2:1 respectively, wherein the alumina is modified with 2 wt% silane coupling agent, wherein the Tg of the polyphenylene sulfide is 95°C, Tm is 295°C;

[0131] 2) mixing modified alumina and polyphenylene sulfide to obtain a mixture;

[0132] 3) Carry out banburying and granulation of the mixture at 330° C. under the protection of an inert gas to obtain pellets;

[0133] 4) Injection molding the pellets at 350°C to obtain an embryo body;

[0134] 5) Warm isostatic pressing the embryo body at 120°C and 200Mpa pressure for 1 hour;

[0135] 6) Heat treatment at 330°C and 80Mpa for 3 hours to obtain the shell body 10;

[0136] 7) Spraying an ethanol solution of polymethyl methacrylate on the surface of the housing body 10, and forming a transparent resin layer 30 after vacuum drying.

[0137] Afte...

Embodiment 2

[0139] The housing assembly 100 of this embodiment is manufactured through the following steps:

[0140] 1) Weighing modified alumina and polyphenylene sulfide with a weight ratio of 2:1 respectively, wherein the alumina is modified with 2 wt% silane coupling agent, wherein the Tg of the polyphenylene sulfide is 95°C, Tm is 295°C;

[0141] 2) mixing modified alumina and polyphenylene sulfide to obtain a mixture;

[0142] 3) Carry out banburying and granulation of the mixture at 330° C. under the protection of an inert gas to obtain pellets;

[0143] 4) Put the pellets in the injection molding machine at the following temperature ranges, and gradually raise the temperature for injection molding: the first temperature range is 270°C to 290°C, the second temperature range is 290°C to 310°C, and the third temperature range is 310°C to 330°C. °C, the fourth temperature section 330 °C to 350 °C, the temperature of the head 330 °C to 350 °C; mold temperature: 160 °C; get the embryo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com