Liquor distillation device

A distillation device and wine liquid technology, which is applied in the directions of fermentation liquid distillation/rectification, distillation separation, distillation adjustment/control, etc., can solve the problem of fixed reflux process of distillation equipment, low utilization rate of raw wine reflux, and limited input-output ratio. Limitation and other issues, to achieve the effect of improving distillation utilization, good practicability, and increasing input-output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them:

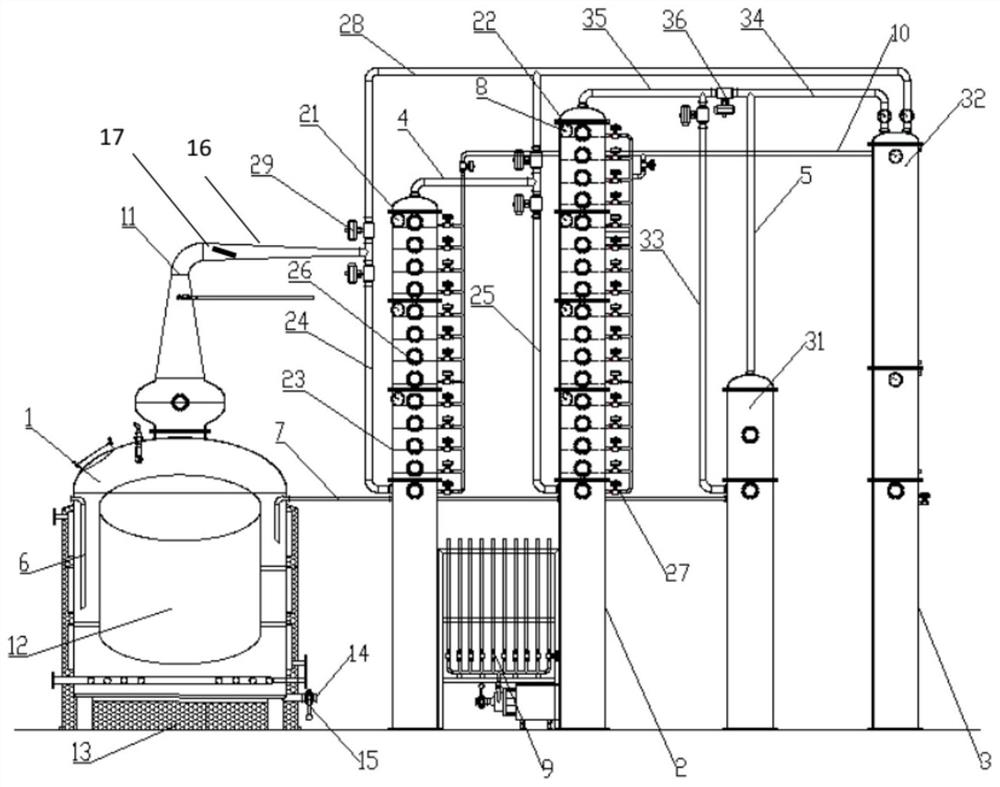

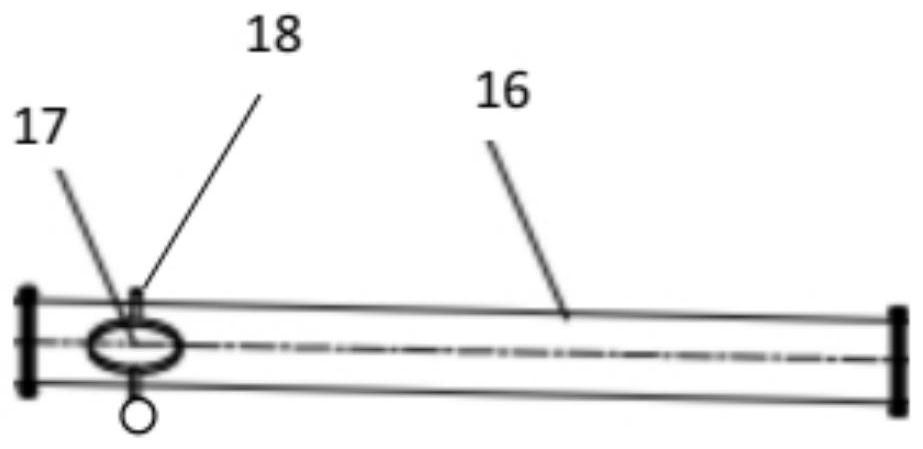

[0027] as attached figure 1 Shown, a kind of wine liquid distillation device comprises distillation kettle 1, rectification tower 2, condenser 3, and the top of distillation tower is fixedly equipped with distillation column 11, and distillation column 11 is connected with rectification tower 2 through first guide pipe 24. The bottom of the rectification tower 2 is connected with the condenser 3 through the condensation pipe 5, and the wine vapor generated in the distillation tower rushes up into the distillation column 11, and is guided by the distillation column 11 into the rectification tower 2 In the process, after being further rectified by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com