Camphor tree hydrolat extraction system and application thereof

An extraction system, camphor tree technology, applied in the field of plant pure dew extraction, can solve the problems of low production efficiency, complicated separation of camphor tree essential oil, etc., and achieve the effects of less loss, reduced loss of pure dew, and fast distillation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

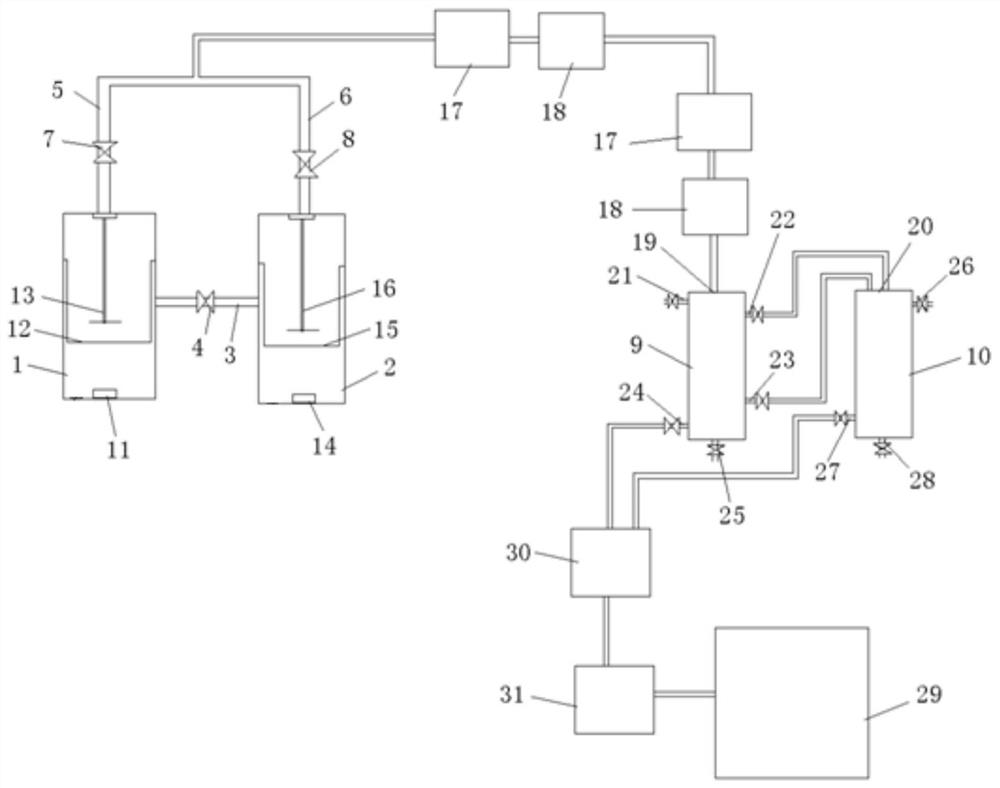

[0037] An extraction system for camphor tree pure dew, comprising an extraction device, a condensation device, a separation device, a centrifugal device, and a collection device, the extraction device includes a distillation pot I1 and a distillation pot II2, and the distillation pot I1 and the distillation pot II2 are arranged side by side Setting, the still pot I1 and the still pot II2 are connected through a connecting pipe 3, the connecting pipe 3 is provided with a communication valve 4, the top of the described still pot I1 is provided with a steam pipe I5, and the described still pot II2 The top of the steam pipe II6 is provided; the steam pipe I5 is provided with a steam valve I7, and the steam pipe II6 is provided with a steam valve II8;

[0038] The condensing device is connected to the steam pipe I5 and the steam pipe II6 at the same time; the separation device includes a primary oil-water separator 9 and a secondary oil-water separator 10, and the top of the primary...

Embodiment 2

[0050] An extraction system for camphor tree pure dew, comprising an extraction device, a condensation device, a separation device, a centrifugal device, and a collection device, the extraction device includes a distillation pot I1 and a distillation pot II2, and the distillation pot I1 and the distillation pot II2 are arranged side by side Setting, the still pot I1 and the still pot II2 are connected through a connecting pipe 3, the connecting pipe 3 is provided with a communication valve 4, the top of the described still pot I1 is provided with a steam pipe I5, and the described still pot II2 The top of the steam pipe II6 is provided; the steam pipe I5 is provided with a steam valve I7, and the steam pipe II6 is provided with a steam valve II8;

[0051] The condensing device is connected to the steam pipe I5 and the steam pipe II6 at the same time; the separation device includes a primary oil-water separator 9 and a secondary oil-water separator 10, and the top of the primary...

Embodiment 3

[0063] An extraction system for camphor tree pure dew, comprising an extraction device, a condensation device, a separation device, a centrifugal device, and a collection device, the extraction device includes a distillation pot I1 and a distillation pot II2, and the distillation pot I1 and the distillation pot II2 are arranged side by side Setting, the still pot I1 and the still pot II2 are connected through a connecting pipe 3, the connecting pipe 3 is provided with a communication valve 4, the top of the described still pot I1 is provided with a steam pipe I5, and the described still pot II2 The top of the steam pipe II6 is provided; the steam pipe I5 is provided with a steam valve I7, and the steam pipe II6 is provided with a steam valve II8;

[0064] The condensing device is connected to the steam pipe I5 and the steam pipe II6 at the same time; the separation device includes a primary oil-water separator 9 and a secondary oil-water separator 10, and the top of the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com