Weld joint appearance prediction method based on improved adaptive fuzzy neural network

A fuzzy neural network, adaptive fuzzy technology, applied in biological neural network models, neural architectures, computational models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

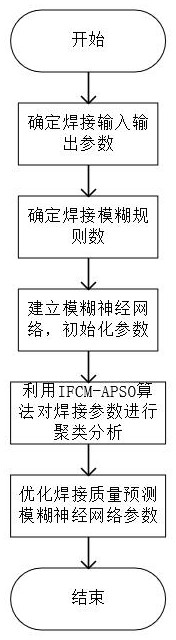

[0072] The first embodiment of the present invention relates to a shape prediction method based on an improved self-adaptive fuzzy neural network, the process of which is as follows figure 2 As shown, the specific steps are as follows:

[0073] Step 1: Initialize the fuzzy neural network for weld shape prediction, and determine the welding fuzzy rules;

[0074] Step 2: Determining the input welding parameter variables of the fuzzy neural network and the output of the fuzzy neural network;

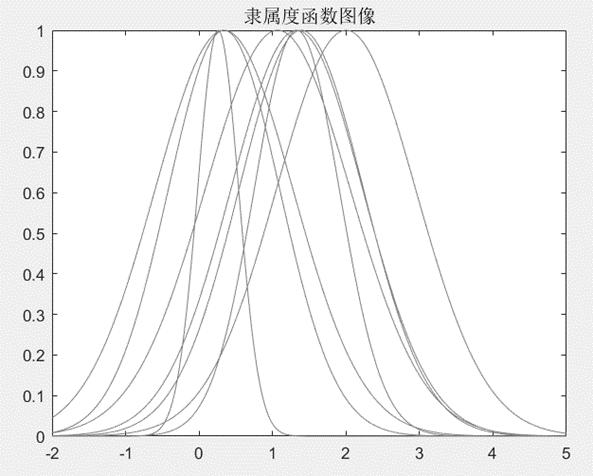

[0075] Step 3: Calculate the welding parameter membership degree of each welding parameter variable according to the welding fuzzy rules determined in step 1;

[0076] Step 4: Use the fusion algorithm based on Intuitive Fuzzy C-Means Clustering (IFCM) and Adaptive Inertia Weighted Particle Swarm Optimization (APSO) to optimize and calculate the unknown parameters in the membership degree of welding parameters, and obtain the welding parameter membership degree of each welding parameter va...

Embodiment 2

[0081] Further, the second embodiment of the present invention relates to a weld shape prediction method based on an improved adaptive fuzzy neural network, which specifically includes the following steps:

[0082] Step 1: Initialize the fuzzy neural network for weld shape prediction, and determine the welding fuzzy rules;

[0083] Use if-then definition rules to describe the weld shape prediction fuzzy neural network. Specifically, the weld shape prediction fuzzy neural network in step 1 can be defined by the following "if-then" rules:

[0084]

[0085] in, is the first Welding Fuzzy Rules, , is the number of welding fuzzy rules; is the welding parameter variable First a fuzzy subset; is the input welding parameter variable, and ; is the number of input welding parameter variables, is the first The output of fuzzy rules, where is the weight coefficient.

[0086] Step 2: Determining the input welding parameter variables of the fuzzy neural network ...

Embodiment 3

[0144] The accuracy and applicability of a fuzzy neural network largely depends on the available training data set, the larger the data set, the wider the input range it covers and the better the resulting network. In order to compare the predictive performance of the patented algorithm, the present invention conducted a welding test on a 3mm thick titanium alloy steel plate, and generated 250 data sets by changing the process parameters. 200 of them are randomly selected for the training of the fuzzy neural network, and the remaining 50 are used for testing the fitting degree of the network; two independent fuzzy neural network models are established, which are respectively used for the prediction of welding width and welding height data. Such as Figure 4Shown are the shape parameters of a typical T-weld.

[0145] According to the input and output dimensions of the training samples, the fuzzy neural network determines the number of input nodes to be 4 and the number of outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com