Cutting waste collecting device of numerical control machine tool

A waste collection, CNC machine tool technology, applied in positioning devices, metal processing machine parts, clamping and other directions, can solve problems such as handling difficulties, and achieve the effect of convenience and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

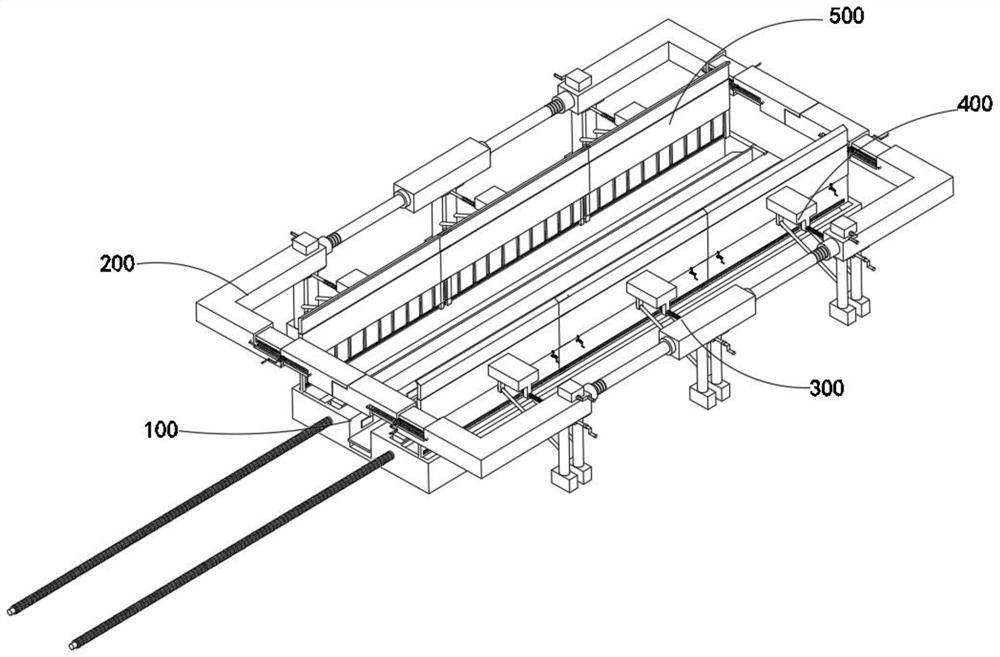

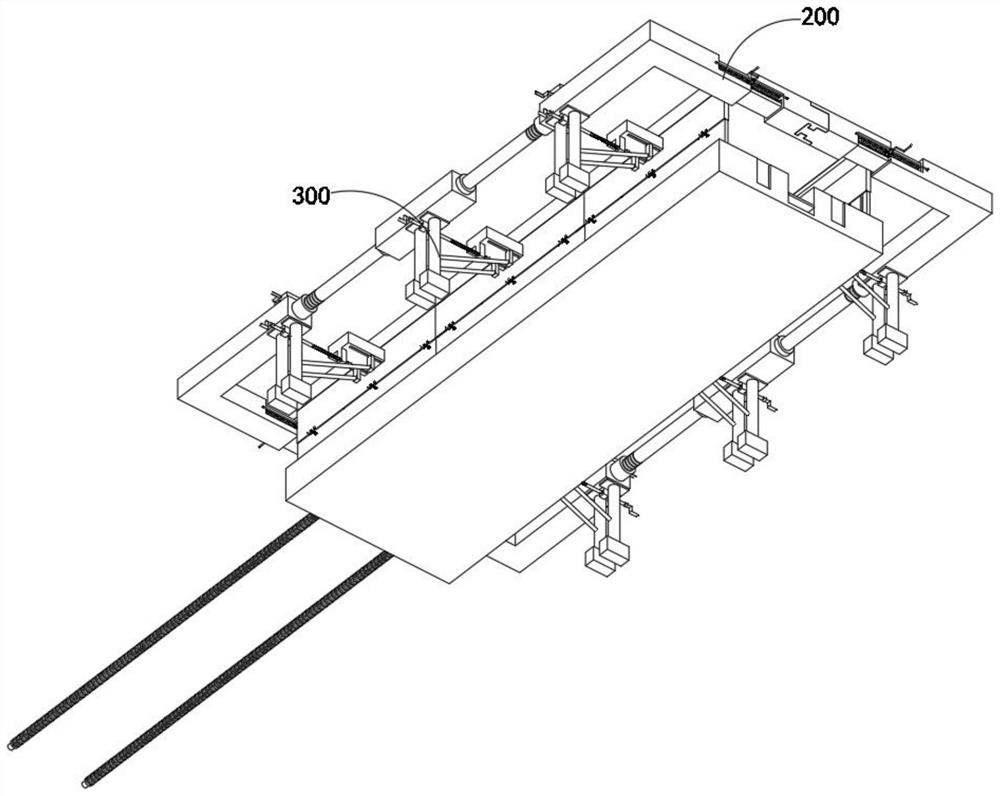

[0052] combine figure 1 , 3 , 4, 7 and 9, the CNC machine tool cutting waste collection device provided by the present invention includes a sheet metal fixture 100, a restraint assembly 200, a length adjustment mechanism 300, a fixation assembly 400 and a material guide mechanism 500, wherein the restraint assembly 200 Located above the sheet metal fixture 100, the length adjustment mechanism 300 is installed in the restraint assembly 200, and the fixation assembly 400 is fixedly installed on the restraint assembly 200 and the length adjustment mechanism 300 through the vertical pile 410 inside it, and the material guide mechanism 500 is installed On the plenum block 450 inside the fixed assembly 400 .

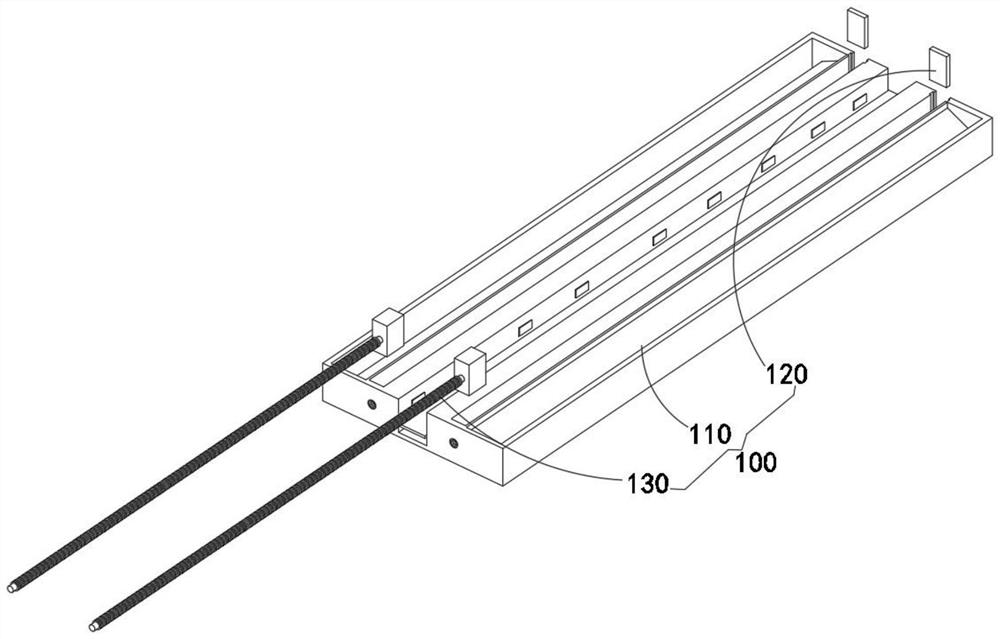

[0053] The sheet metal fixture 100 includes a base 110, a partition 120, a compression assembly 130, a compression assembly 111, an anti-slip assembly 112, and a slide bar assembly 113, while the constraint assembly 200 includes a main control 210, a handle 220, a first adapt...

Embodiment 2

[0058] combine image 3 As shown, on the basis of the first embodiment, by setting the partition plate 120 and the compression assembly 130, when the inside of the two inclined slides is filled with metal scraps, the screw on the compression assembly 130 is used to push the rectangular compact at one end. The extrusion of the metal scraps can make the metal scraps easy to form, thereby realizing the unified treatment of the metal scraps. The metal sheet fixing part 100 also includes a partition 120 inserted in one end of the two inclined slideways and a threaded connection Compression combination 130 at the other end of the two inclined slides.

Embodiment 3

[0060] combine Figure 6 As shown, on the basis of Embodiment 1, a base 310 and a half-screw 320 are set, and one end of the half-screw 320 is fixedly installed inside the base 310. When the base 310 is controlled to rotate, the half-screw 320 will move along the The inner cavity of the main control 210 is rotated so as to realize rapid contraction of the device. The length adjustment mechanism 300 includes a half-screw 320 connected to the inner cavity of the main control 210 and a base 310 installed on the outer end of the half-screw 320 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com