Bag clamping mechanism of automatic plastic particle packaging machine

A technology of automatic packaging machine and plastic granules, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. Good lasting effect, simple structure and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

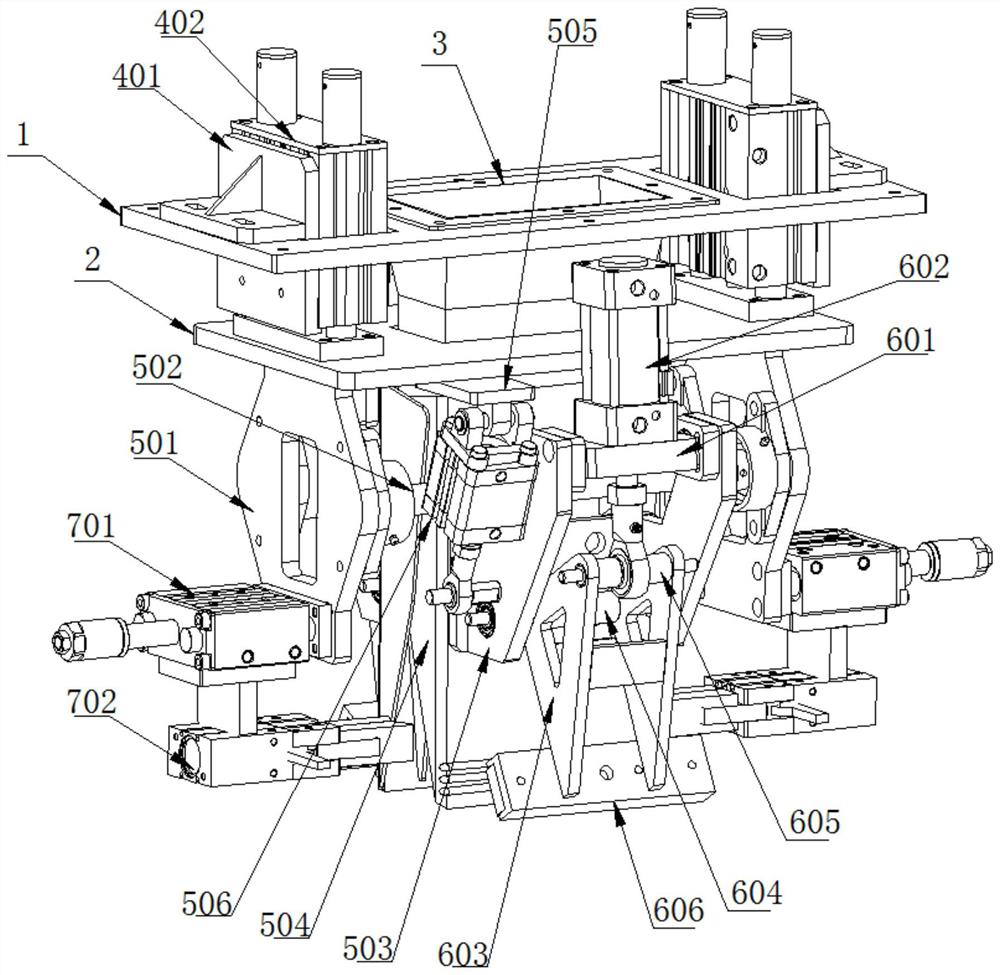

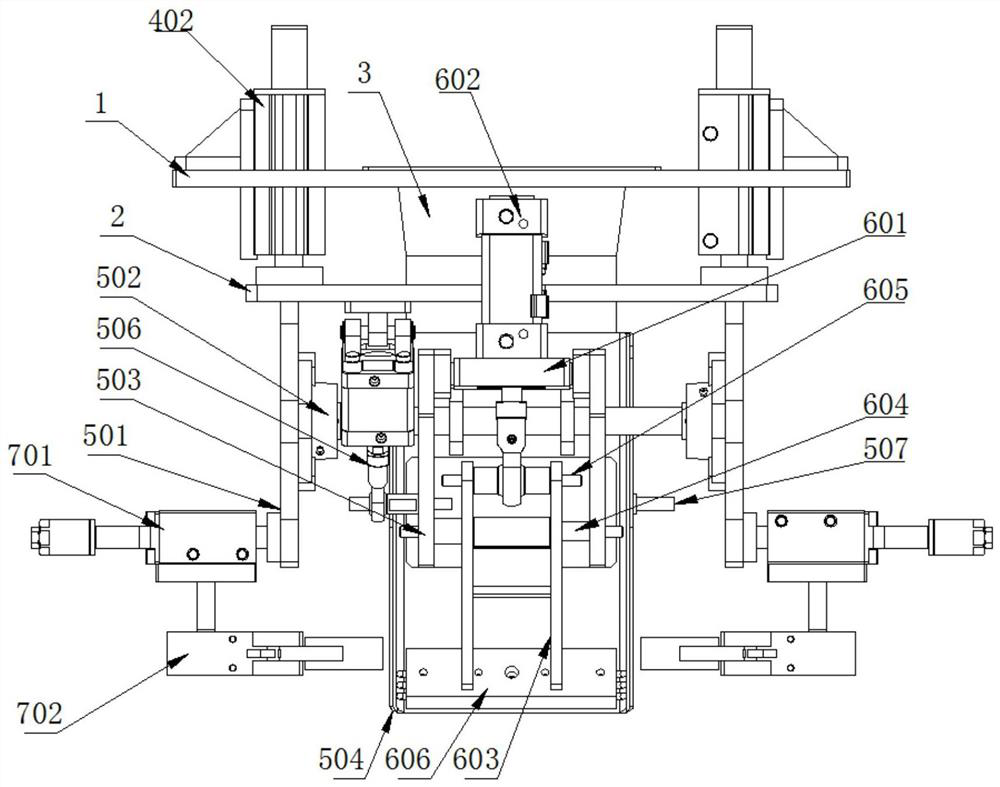

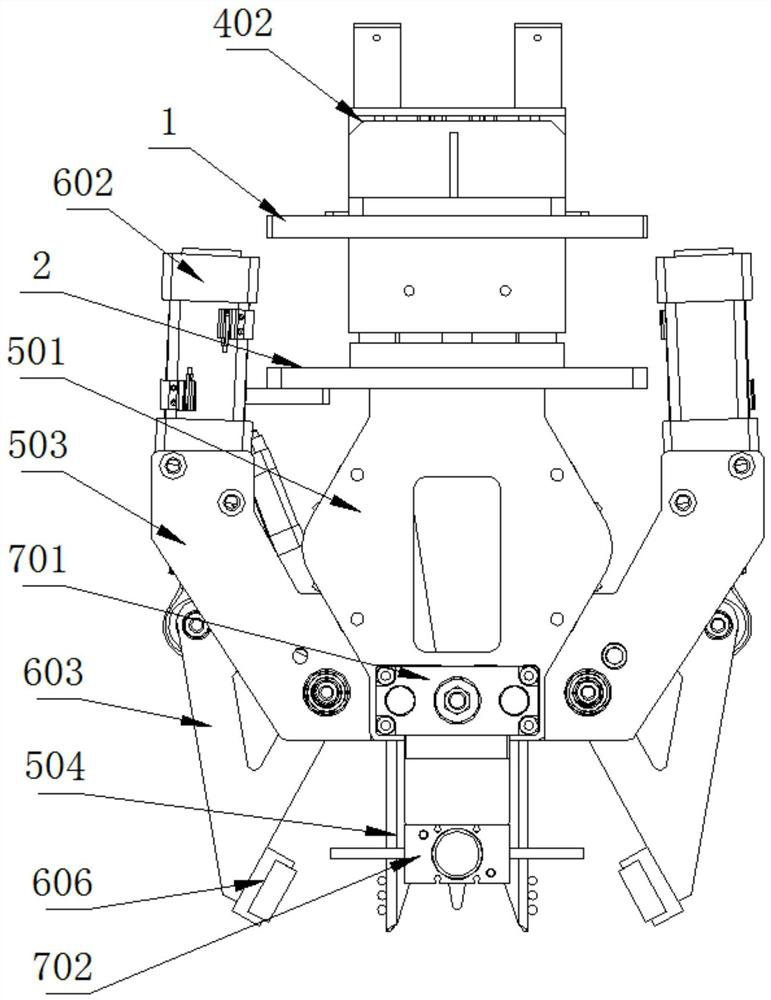

[0036] Such as Figure 1-3 As shown, the bag clamping mechanism of the plastic particle automatic packaging machine includes a fixed plate 1, several first cylinders 402 installed on the fixed plate 1, a moving plate 2 connected to the lower end of the first cylinder 402, and a moving plate connected to the lower end of the moving plate 2. Several mounting brackets 501, a blanking rate control mechanism connected to the mounting bracket 501, several lateral bag clamping mechanisms and a bag edge clamping mechanism connected to the blanking rate control mechanism, the horizontal bag clamping mechanism is used for clamping The bags located on both sides of the blanking rate control mechanism, the bag side clamping mechanism is used to clamp the bag attached to the blanking rate control mechanism;

[0037] The blanking rate control mechanism includes several limit shafts 502 connected to the mounting bracket 501, several inclined adjustment plates 503 movably connected to the lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com