Release silicone oil capable of improving anchoring property of PEK base material and preparation method thereof

A release and anchoring technology, applied in the direction of coating, etc., can solve the problems of desiliconization, hindering the adhesion of solvent-free release silicone oil coating and coating layer, and coating peeling off, so as to achieve increased anchoring and high residual adhesion Efficiency, coating smooth and dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

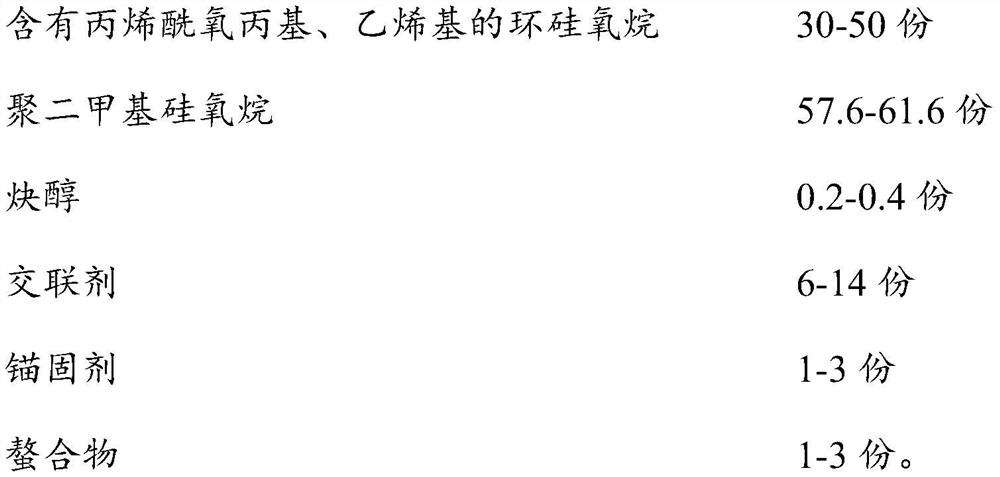

[0031] 40 parts of cyclosiloxane containing acryloxypropyl and vinyl groups, 59.8 parts of polydimethylsiloxane, 0.2 parts of alkynyl alcohol, 10 parts of crosslinking agent, 2 parts of anchoring agent, and 2 parts of chelate compound.

[0032] Among them, cyclosiloxane containing acryloyloxypropyl group and vinyl group, polydimethylsiloxane, and alkynyl alcohol are used as the main agent of the release silicone oil.

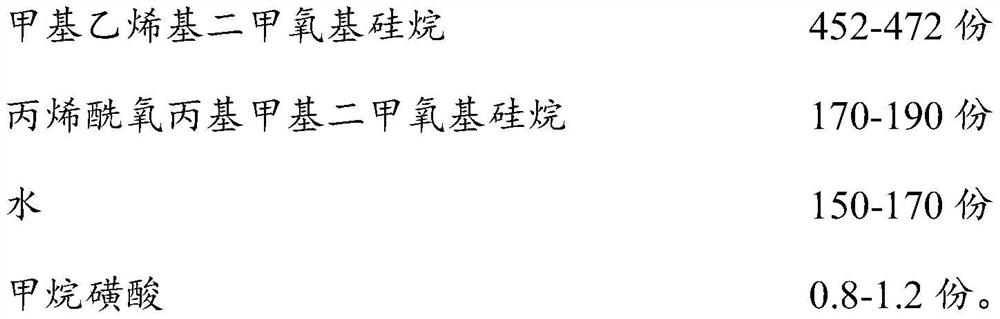

[0033] Among them, the cyclosiloxane containing acryloyloxypropyl and vinyl contains the following components in parts by weight: 462 parts of methylvinyldimethoxysilane, acryloyloxypropylmethyldimethoxysilane 180 parts of methoxysilane, 160 parts of water, and 1 part of methanesulfonic acid.

[0034] Wherein, the structural formula of cyclosiloxane containing acryloyloxypropyl and vinyl is: Wherein, a is 0-3, b is 1-4, and a+b+c is 5-10. In this example, cyclosiloxane containing acryloxypropyl and vinyl groups is used as one of the main ingredients of the re...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is:

[0053] 30 parts of cyclosiloxane containing acryloxypropyl and vinyl groups, 57.6 parts of polydimethylsiloxane, 0.4 parts of alkynyl alcohol, 6 parts of crosslinking agent, 1 part of anchoring agent, and 1 part of chelate compound.

[0054] Among them, the cyclosiloxane containing acryloxypropyl and vinyl contains the following components in parts by weight: 452 parts of methylvinyldimethoxysilane, acryloyloxypropylmethyldimethoxysilane 170 parts of methoxysilane, 150 parts of water, and 0.8 parts of methanesulfonic acid.

[0055] Among them, the viscosity of polydimethylsiloxane is 200 mPa·s.

[0056] Wherein, the mass ratio of the first crosslinking agent to the second crosslinking agent is 3:1.

[0057] Wherein, the first crosslinking agent is polymethylsiloxane with a hydrogen content of 1.1%, and its viscosity at 25° C. is 50 mPa·s.

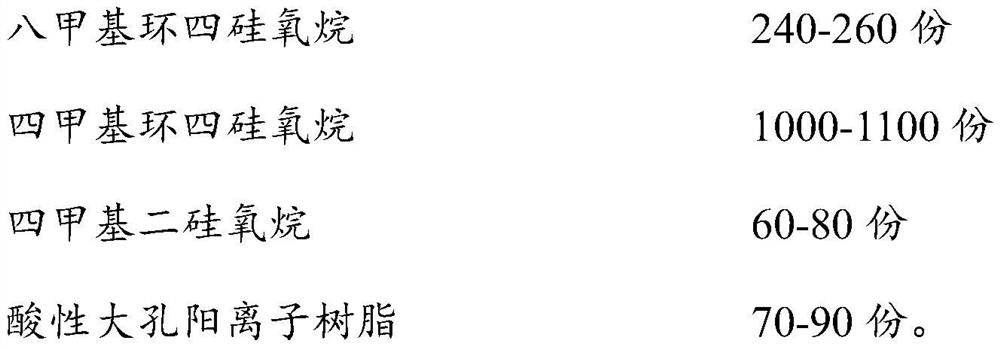

[0058] Wherein, the first crosslinking agent comprises the followi...

Embodiment 3

[0062] The difference between this embodiment and embodiment 1 is:

[0063] 50 parts of cyclosiloxane containing acryloxypropyl and vinyl groups, 61.6 parts of polydimethylsiloxane, 0.4 parts of alkynyl alcohol, 14 parts of crosslinking agent, 3 parts of anchoring agent, and 3 parts of chelate compound.

[0064] Among them, the cyclosiloxane containing acryloyloxypropyl and vinyl contains the following components in parts by weight: 472 parts of methylvinyldimethoxysilane, acryloyloxypropylmethyl dimethoxysilane 190 parts of methoxysilane, 170 parts of water, and 1.2 parts of methanesulfonic acid.

[0065] Among them, the viscosity of polydimethylsiloxane is 1000 mPa·s.

[0066] Wherein, the mass ratio of the first crosslinking agent to the second crosslinking agent is 5:1.

[0067] Wherein, the first crosslinking agent is polymethylsiloxane with a hydrogen content of 1.3%, and its viscosity at 25° C. is 60 mPa·s.

[0068] Wherein, the first crosslinking agent comprises the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com