Dye removing device for yarn dyeing

A yarn dyeing and dyeing technology, applied in the direction of removal of liquid/gas/vapor, textile material treatment, textile material carrier treatment, etc., can solve the problems of waste, yarn damage, slow degradation, etc., to achieve easy operation, reduce yarn Line damage, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A dye removal device for yarn dyeing, such as Figure 1-Figure 3 As shown, it includes a base 1 , a placing component 2 and a cleaning component 3 , the placing component 2 is provided on the top left rear side of the base 1 , and the cleaning component 3 is provided on the top rear side of the base 1 .

[0029] People wind the yarn on the placing component 2, and the yarn passes through the cleaning component 3 to clean the dyed yarn, so as to achieve the effect of simple structure.

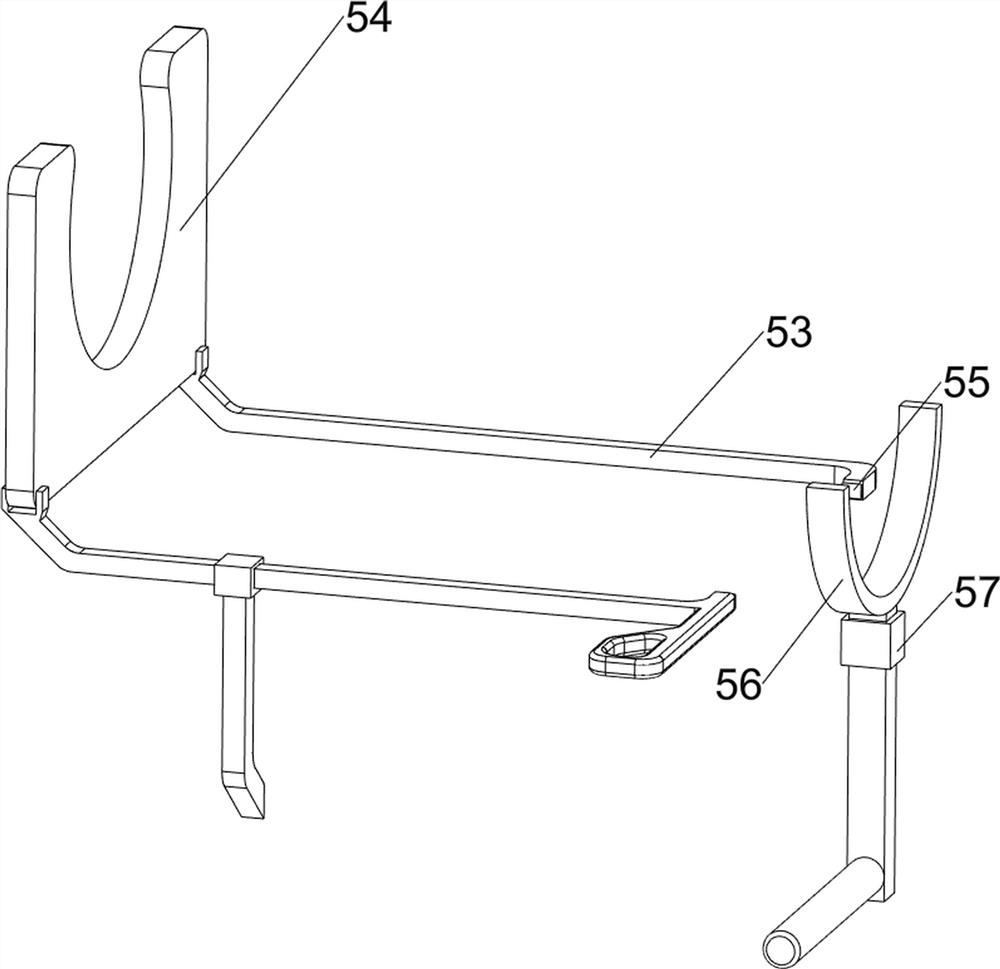

[0030] The placement assembly 2 includes a first support rod 21, a first baffle plate 22, a first placement rod 23, a first connecting rod 24, and a guide ring 25. The top left rear side of the base 1 is provided with a first support rod 21, the first support The rod 21 is provided with a first baffle 22, the first baffle 22 is provided with a first placement rod 23, the right side of the first baffle 22 is provided with a first connecting rod 24, and the first connecting rod 24 is provid...

Embodiment 2

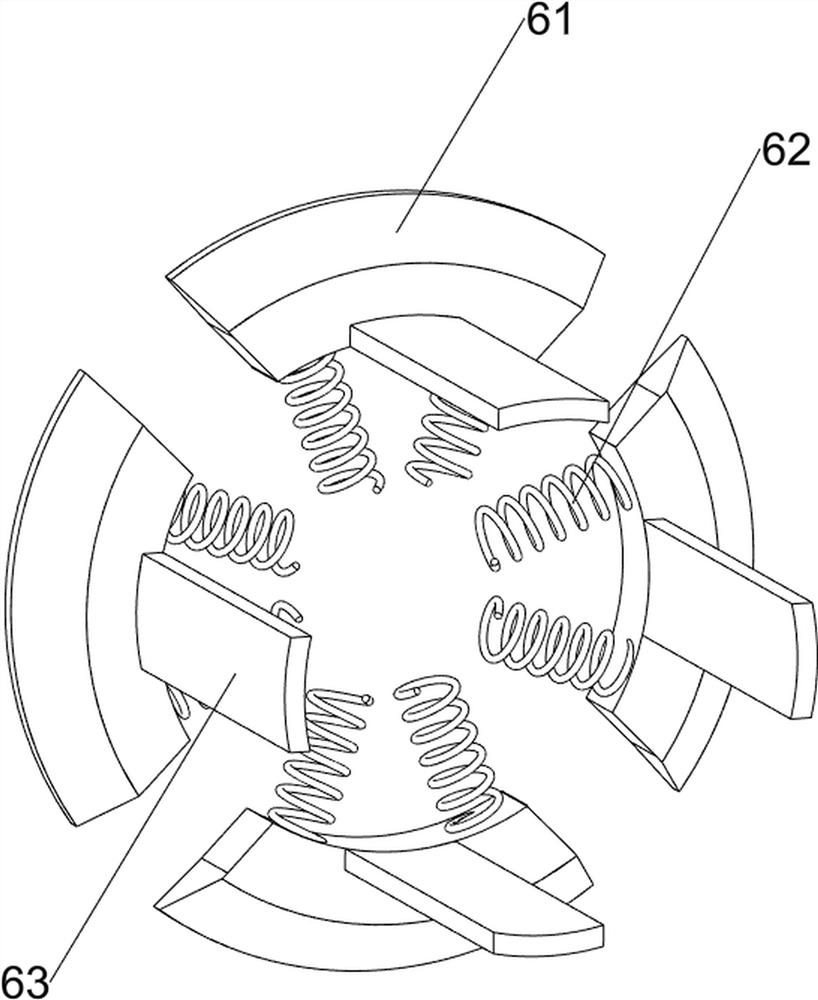

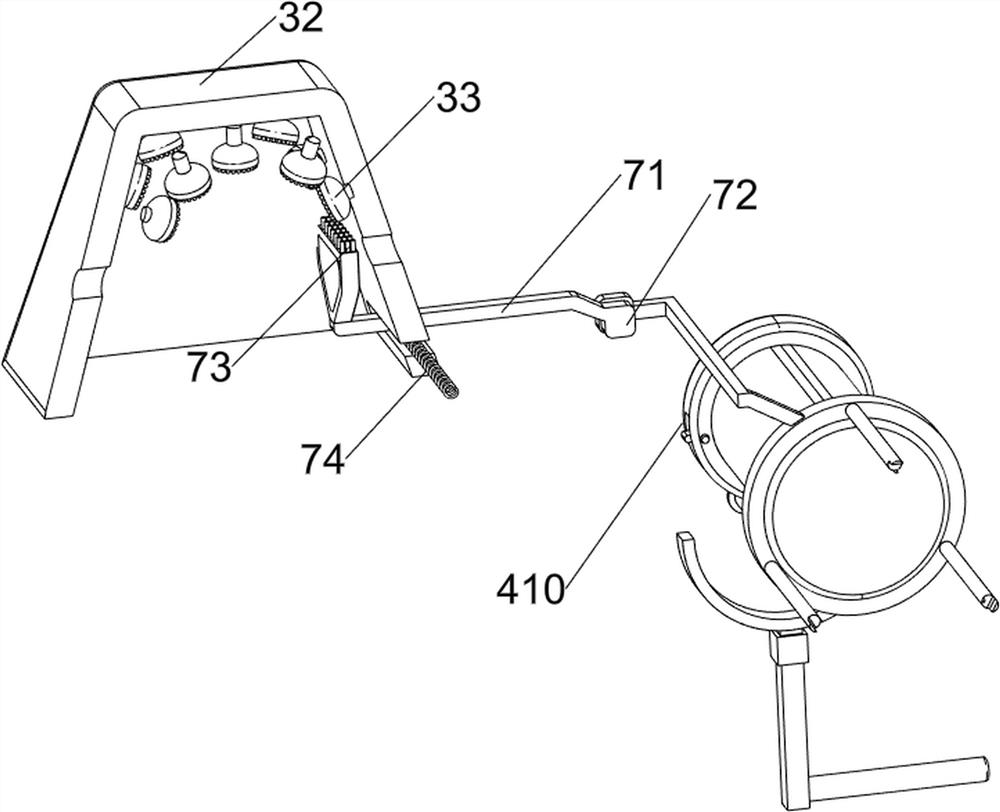

[0034] On the basis of Example 1, such as Figure 4-Figure 9 As shown, it also includes a material retrieving assembly 4, and the retrieving assembly 4 includes a third support rod 41, a servo motor 42, a second connecting rod 43, a first blocking block 44, a wedge block 45, a rotating shaft 46, a rotating rod 47, The second blocking block 48, the torsion spring 49 and the fourth support rod 410, the left and right sides of the base 1 top front side are symmetrically provided with the third support rod 41, the third support rod 41 is slidably provided with a servo motor 42, and the servo motor 42 is connected There is a second connecting rod 43, the top of the second connecting rod 43 is provided with a first stop block 44, the output shaft of the servo motor 42 is connected with a rotating shaft 46, a disc is placed on the rear side of the rotating shaft 46, and a rotating rod is arranged on the rear side of the disc 47, left and right symmetrical rotation on the disc is prov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap