Fog column automatic detection system based on machine vision

An automatic detection and machine vision technology, applied in instruments, measuring devices, image data processing, etc., can solve problems such as inconvenient operation of fog columns and unstable measurement results, so as to solve randomness, make detection results clear and easy to understand, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

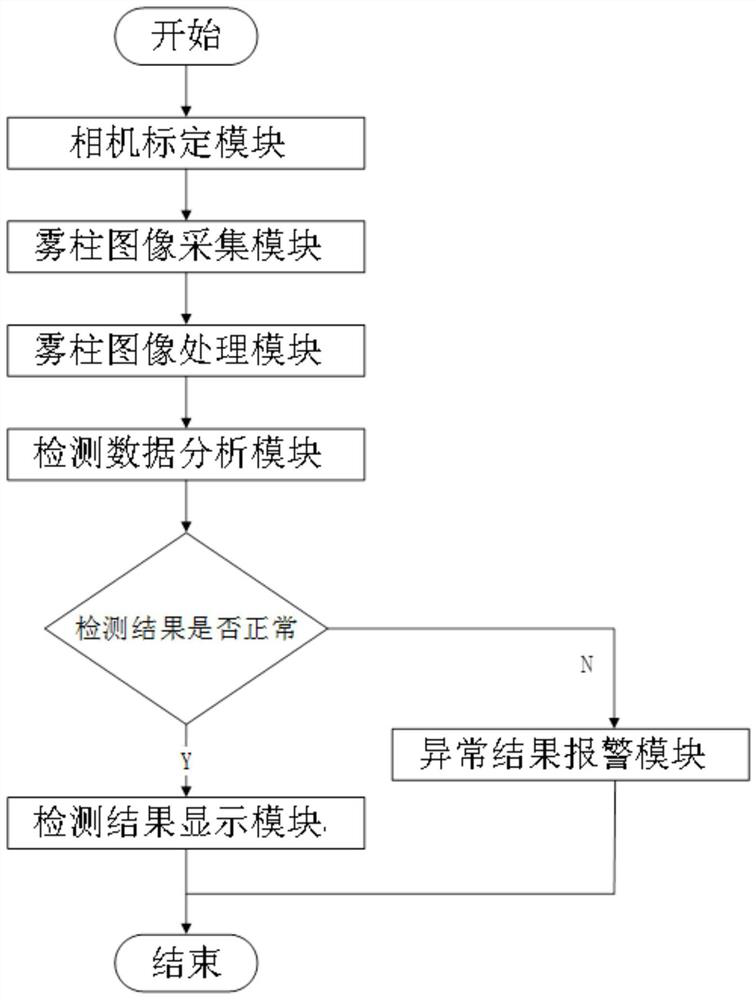

[0055] A fog column automatic detection system based on machine vision, such as figure 1 As shown, it includes a camera calibration module, a fog column image acquisition module, a fog column image processing module, a detection data analysis module and a detection result display module.

[0056] The camera calibration module is used to calibrate each image acquisition device in the fog column image acquisition module (the image acquisition equipment is calibrated by Zhang Zhengyou’s checkerboard calibration method) to correct image distortion and facilitate subsequent image processing, and use the calibration results to analyze the camera internal connection between.

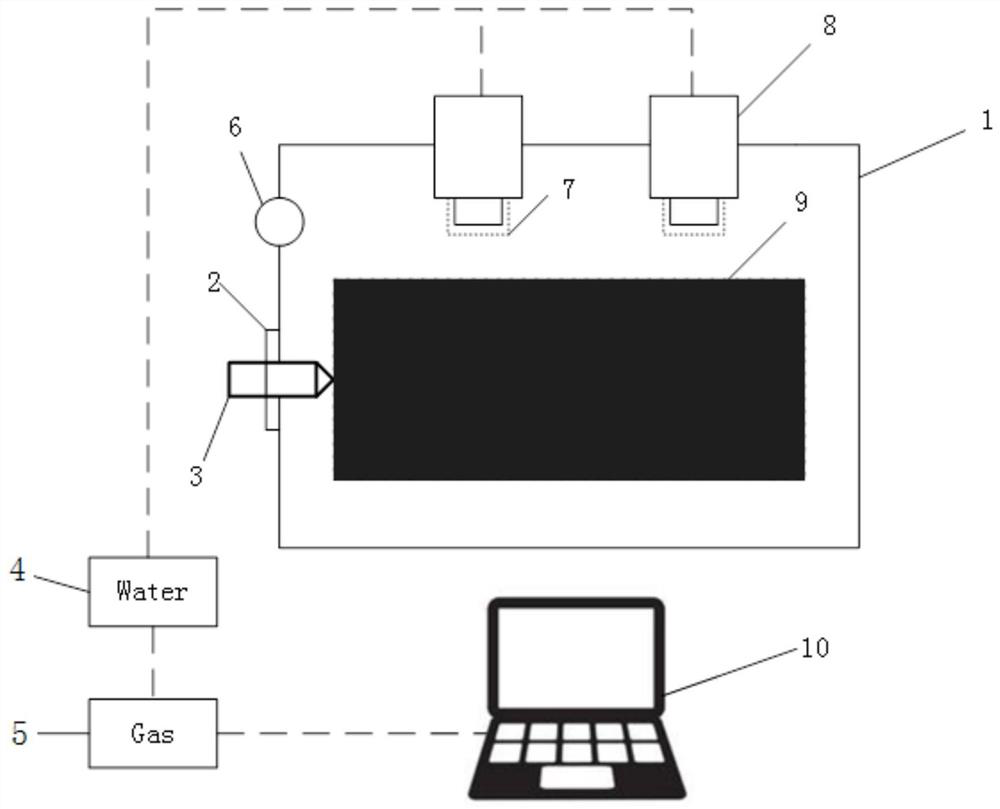

[0057] The fog column image acquisition module is used to collect the fog column image sprayed by the nozzle, such as figure 2 As shown, it includes platform 1, fixing parts 2, nozzles 3, water pump 4, air pump 5, air pressure gauge 6, fill light 7, fog column image acquisition equipment 8, background cloth 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com