STM32-based automobile brake disc metal flaw detection system and method thereof

An automobile brake and metal flaw detection technology, applied in the field of flaw detection, can solve problems such as unsuitable product transformation and promotion, electromagnetic radiation hazards, safety hazards, etc., and achieve the effects of avoiding the probability of defective products being missed, no electromagnetic radiation pollution, and cost economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

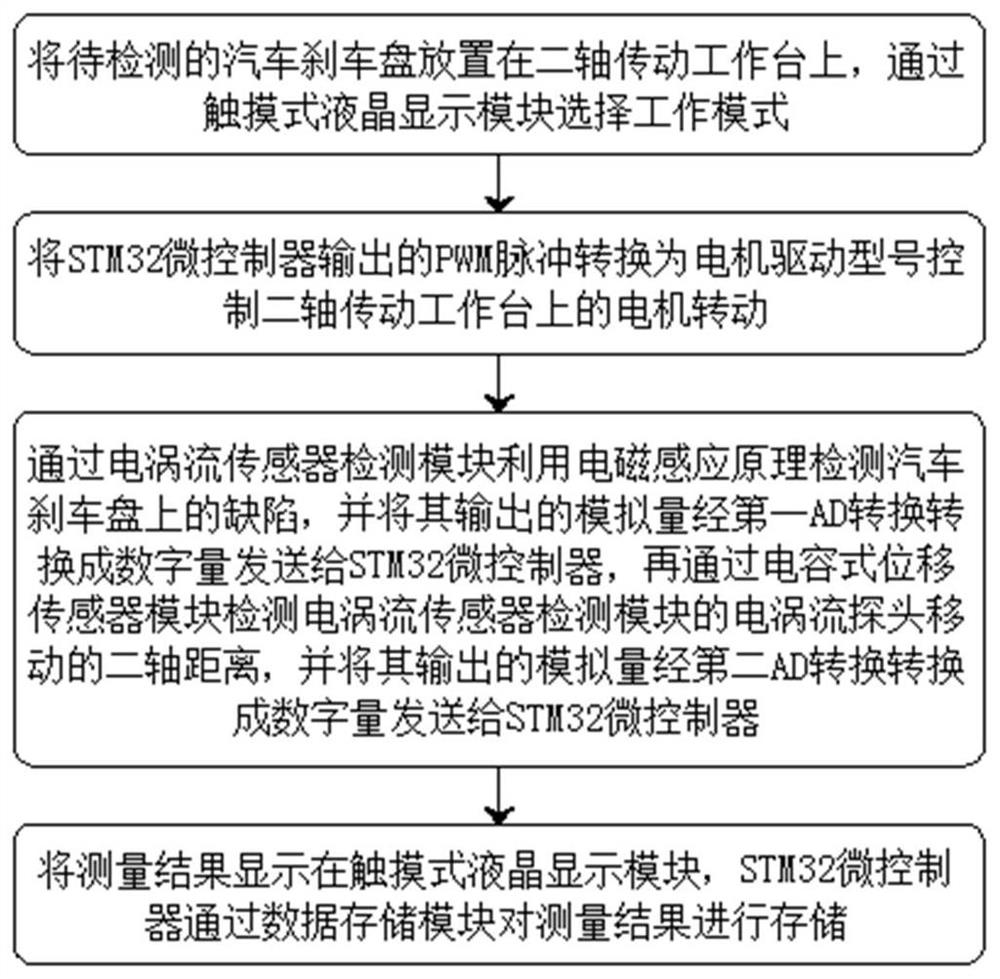

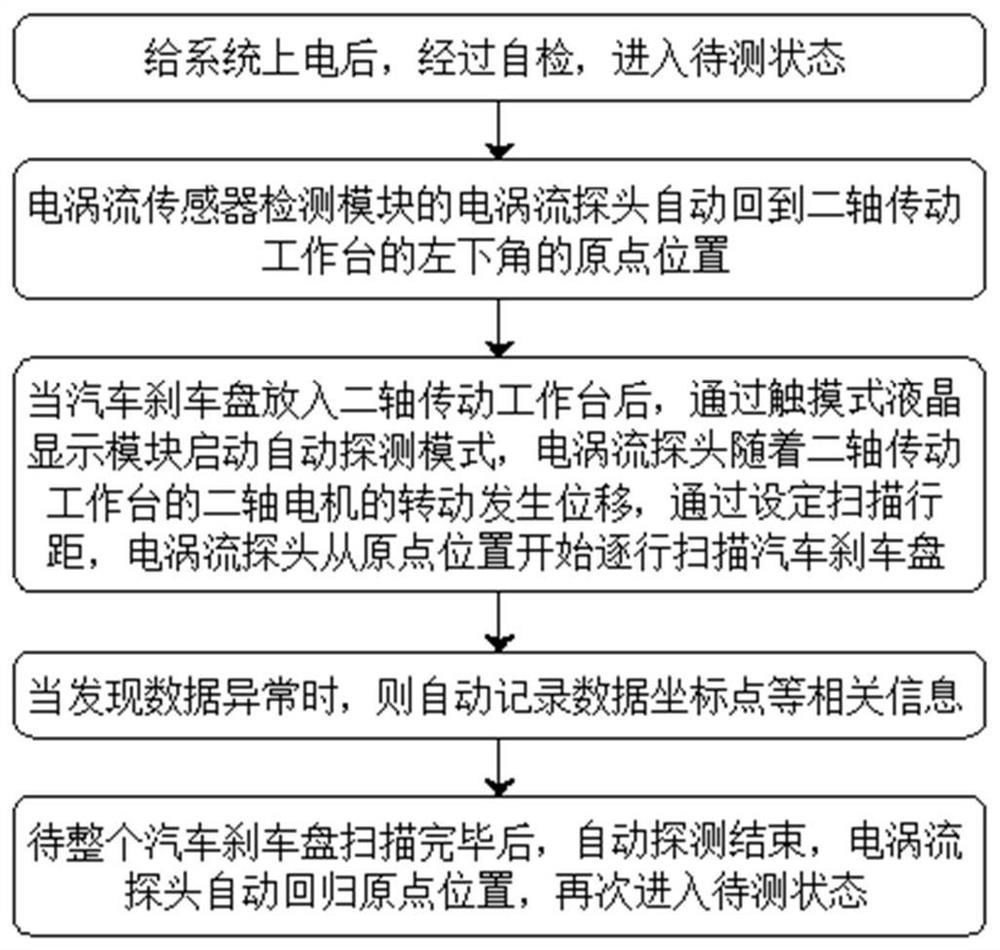

[0049] see Figure 1-10 , the present invention provides a technical solution:

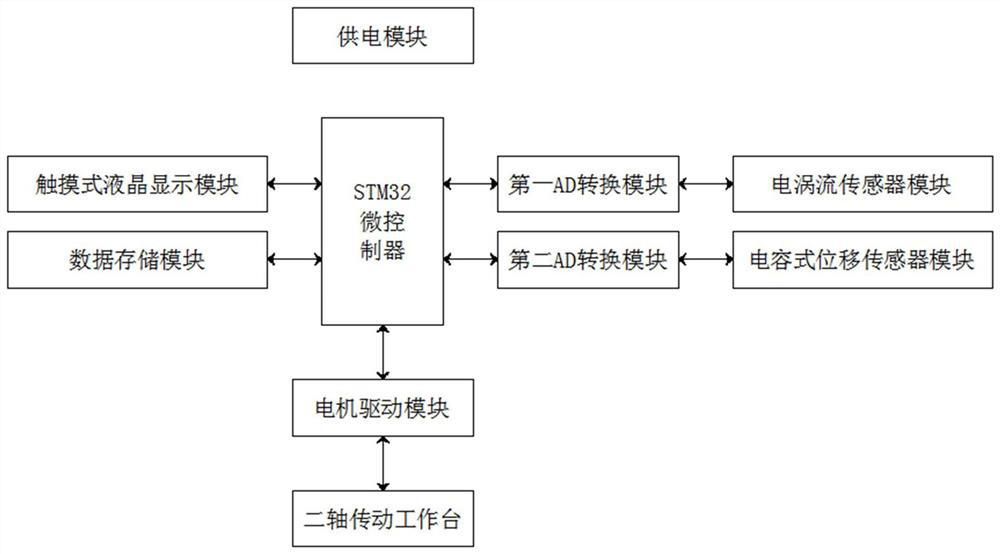

[0050]A metal flaw detection system for automobile brake discs based on STM32, including an STM32 microcontroller, an eddy current sensor detection module, a capacitive displacement sensor module, a motor drive module, a first AD conversion module, a second AD conversion module, and a touch-type liquid crystal display module, data storage module and two-axis drive table;

[0051] The STM32 microcontroller is electrically connected to the motor drive module, the first AD conversion module, the second AD conversion module, the touch liquid crystal display module, and the data storage module, and the second An AD conversion module is electrically connected to the eddy current sensor detection module, the second AD conversion module is electrically connected to the capacitive displacement sensor module, and the motor drive module is electrically connected to the two-axis transmission workbench. conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com