Low-cost high-performance sintered neodymium-iron-boron permanent magnet material and preparation process thereof

A permanent magnet material and preparation technology, which is applied in the direction of magnetic material, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of high price and limited heavy rare earth resources, and achieve cost reduction, good coercive force, The effect of high coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

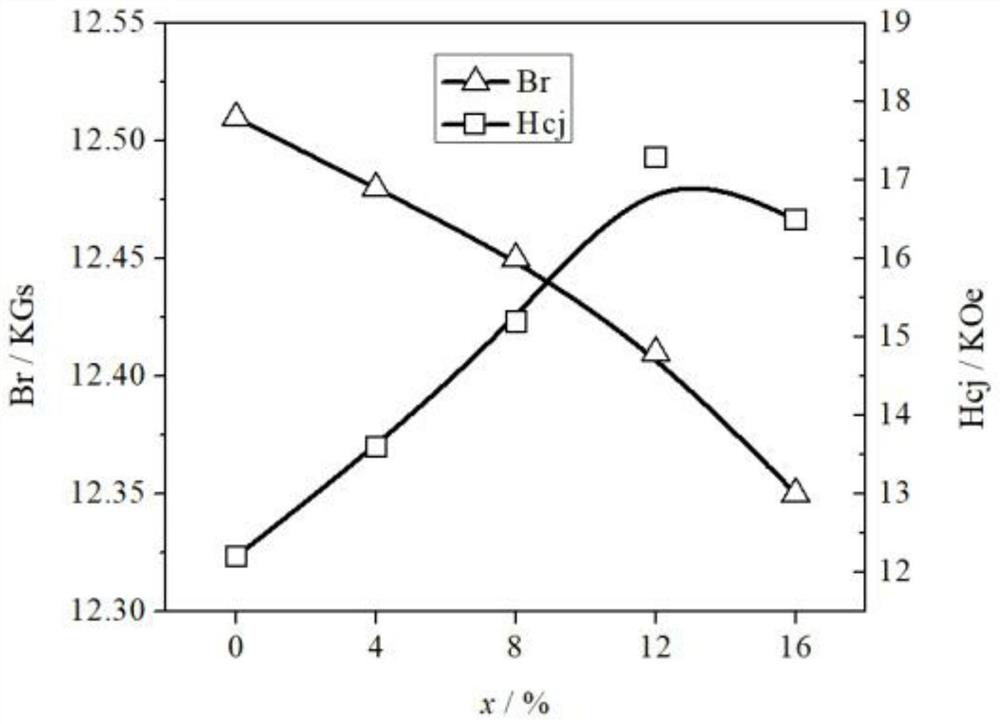

[0031] Preparation of a low-cost and high-performance sintered NdFeB permanent magnet material: the preparation process of the low-cost and high-performance sintered NdFeB permanent magnet material includes the following steps:

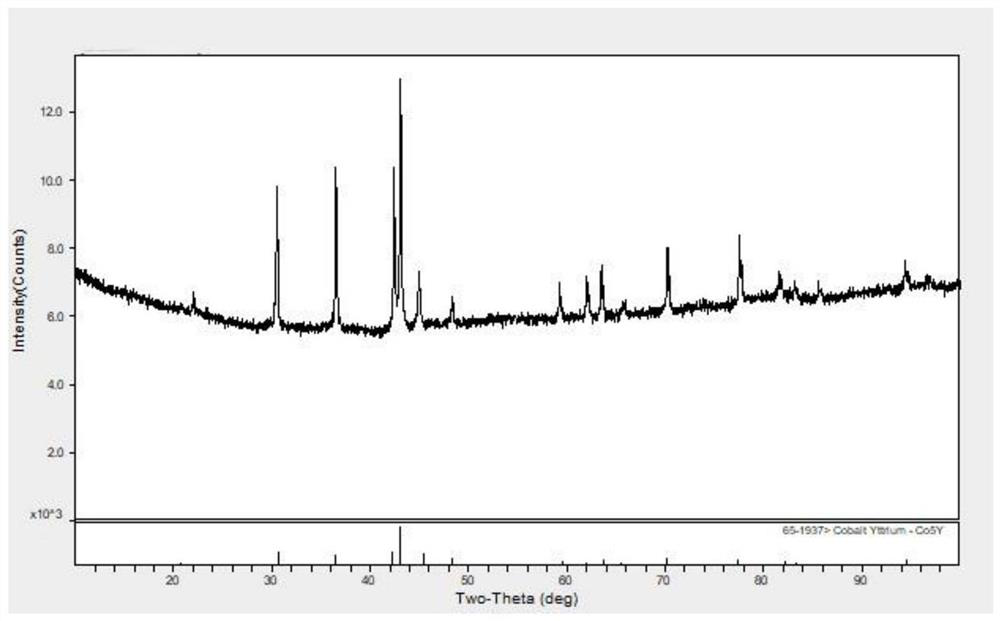

[0032] (1) Ingredients: the YCeCo5 type powder is ingredient according to the following atomic ratio, Y 12.50 Ce 4.17 co 77.83 Mo 2.5 Ga 3 ;

[0033] (2) Adopt the ZDL-600 vacuum strip furnace produced by Aifake Vacuum Equipment Co., Ltd., and start to bake the material when the vacuum degree of the smelting belt furnace is less than 3Pa. When the vacuum degree is lower than 5Pa, fill with argon and increase the power to 520KW for smelting. When the metal is completely melted, adjust the power to 500KW for smelting. When the temperature reaches 1430-1450℃, then adjust the water-cooled copper roller speed to 45rpm, control The temperature of the inlet water is 10-15°C to start casting to obtain the flake alloy; the thickness of the prepared flake ...

Embodiment 2

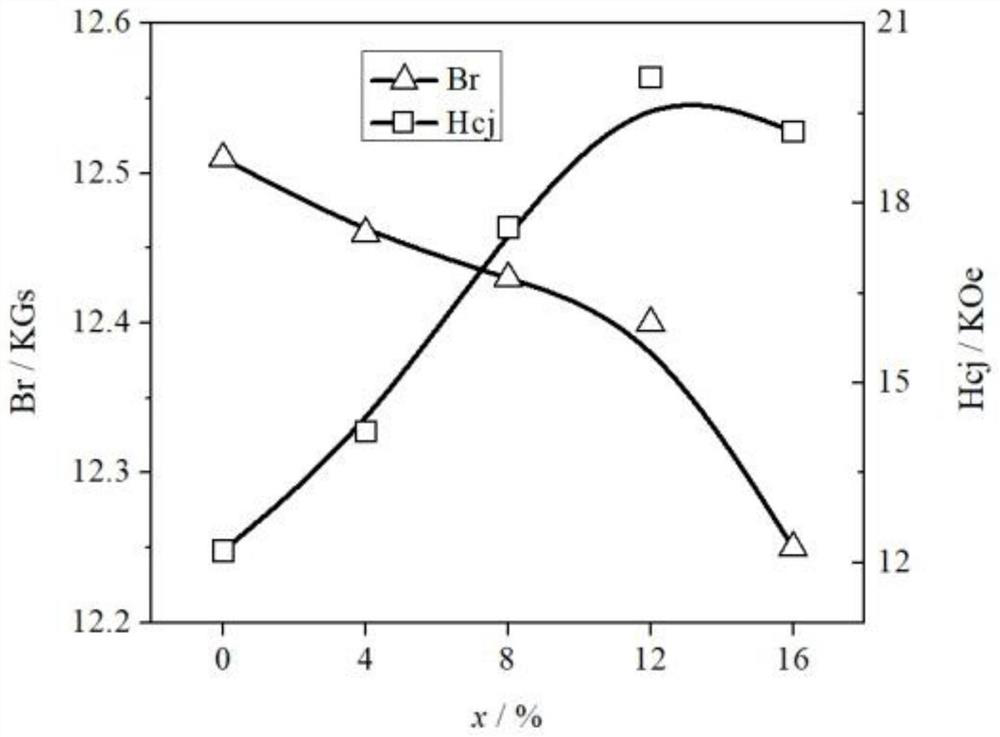

[0043] Preparation of a low-cost and high-performance sintered NdFeB permanent magnet material: the preparation process of the low-cost and high-performance sintered NdFeB permanent magnet material includes the following steps:

[0044] (1) Ingredients: the YCeCo5 type powder is ingredient according to the following atomic ratio, Y 8.34 Ce 8.33 co 69.33 Mo 5.0 Ga 9 ;

[0045] (2) Adopt the ZDL-600 vacuum strip furnace produced by Aifake Vacuum Equipment Co., Ltd., and start to bake the material when the vacuum degree of the smelting belt furnace is less than 3Pa. When the vacuum degree is lower than 5Pa, fill with argon and increase the power to 520KW for smelting. When the metal is completely melted, adjust the power to 500KW for smelting. When the temperature reaches 1430-1450℃, then adjust the water-cooled copper roller speed to 45rpm, control The temperature of the inlet water is 10-15 ℃ to start casting to obtain the flake alloy; the thickness of the prepared flake a...

Embodiment 3

[0055] Preparation of a low-cost and high-performance sintered NdFeB permanent magnet material: the preparation process of the low-cost and high-performance sintered NdFeB permanent magnet material includes the following steps:

[0056] (1) Ingredients: the YCeCo5 type powder is ingredient according to the following atomic ratio, Y 4.17 Ce 12.50 co 69.83 Mo 7.5 Ga 6 ;

[0057] (2) Adopt the ZDL-600 vacuum strip furnace produced by Aifake Vacuum Equipment Co., Ltd., and start to bake the material when the vacuum degree of the smelting belt furnace is less than 3Pa. When the vacuum degree is lower than 5Pa, fill with argon and increase the power to 520KW for smelting. When the metal is completely melted, adjust the power to 500KW for smelting. When the temperature reaches 1430-1450℃, then adjust the water-cooled copper roller speed to 45rpm, control The temperature of the inlet water is 10-15 ℃ to start casting to obtain the flake alloy; the thickness of the prepared flake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com