A kind of nano silver solder paste low temperature large area uniform sintering method

A nano-silver, large-area technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of high sintering temperature, higher sintering uniformity requirements, and inability to achieve, to improve sintering uniformity and avoid low connection strength. , the effect of improving the wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

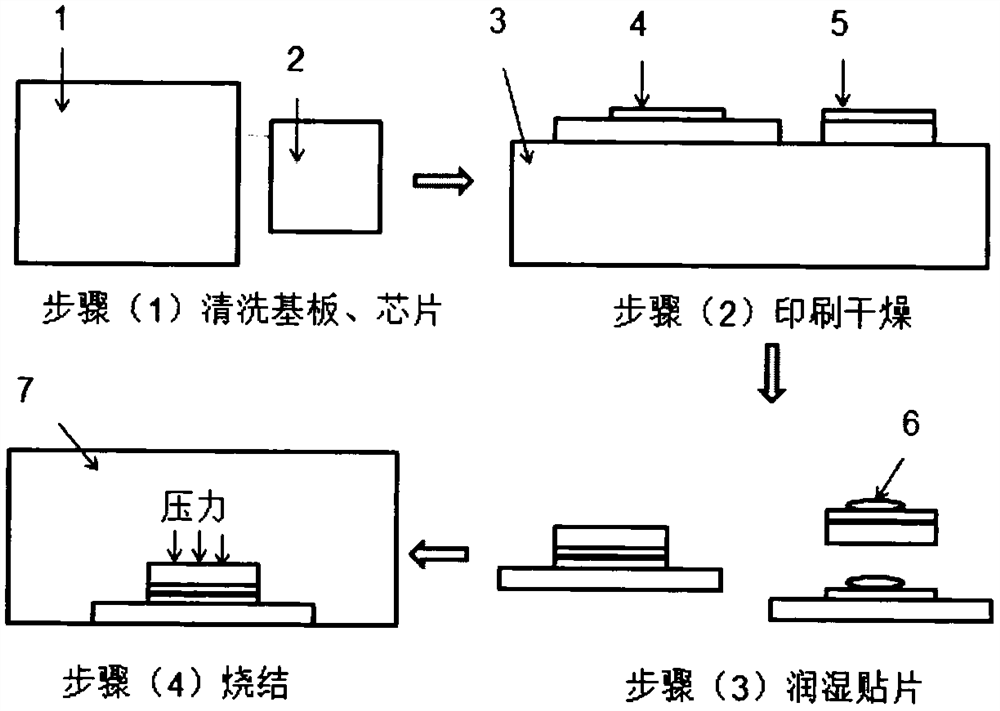

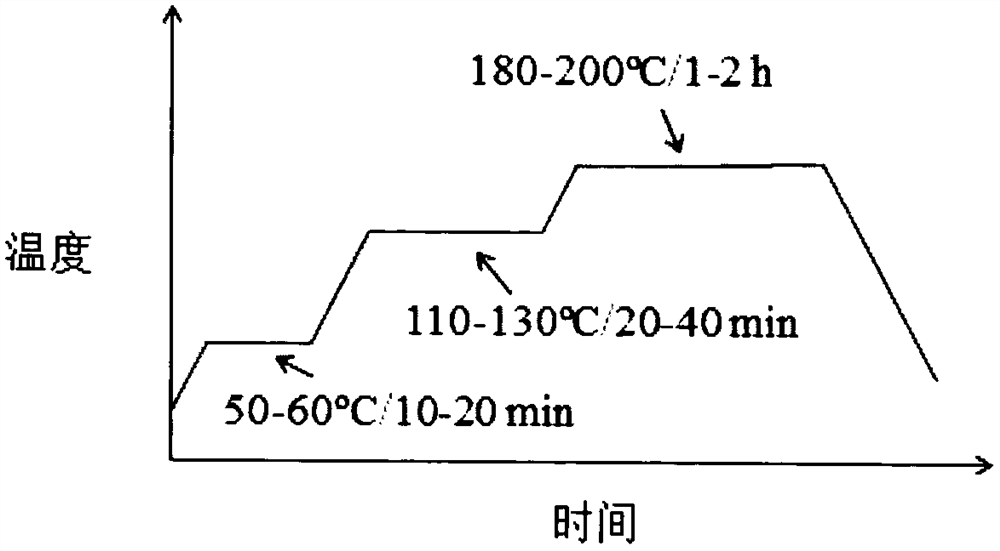

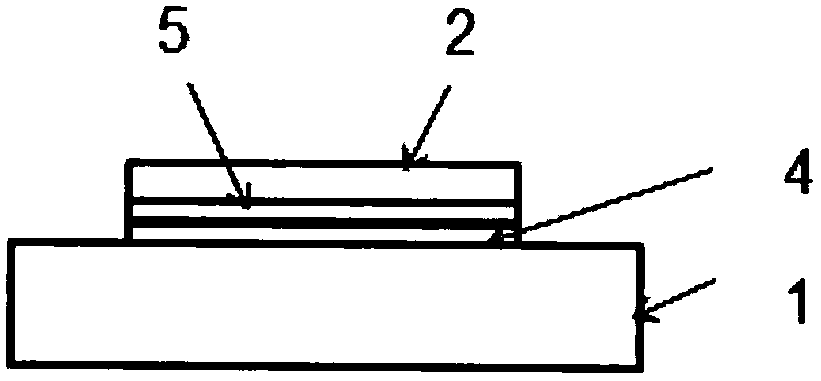

[0039] In this example, the process method for uniform sintering of nano-silver solder paste at low temperature and large area is as follows:

[0040] (1) Set the area to 400mm 2 The chips and metal substrates were ultrasonically cleaned in absolute ethanol for 1 min to remove the oily dirt adhering to the surface of the metal substrates, and then dried at 50°C for 1 min using a hot air blower to fully volatilize the absolute ethanol and water on the surfaces of the substrates and chips.

[0041] (2) Print 50 μm thick nano-silver solder paste on the substrate and chip connection surfaces cleaned in step (1), place the printed solder paste substrate and chip on a heating table and heat to 110°C for 20 minutes to dry to make the solder paste The low-temperature solvent and adhesive in the medium are fully decomposed and volatilized. After drying, the substrate and chip are removed and cooled to room temperature quickly.

[0042] (3) drop an organic solvent on the nano-silver so...

Embodiment 2

[0045] In this example, the process method for uniform sintering of nano-silver solder paste at low temperature and large area is as follows:

[0046] (1) Set the area to 400mm 2 The chips and metal substrates were ultrasonically cleaned in absolute ethanol for 1.5 minutes to remove the oily dirt adhering to the surface of the metal substrates, and then dried at 75°C for 1.5 minutes using a hot air blower to fully volatilize the absolute ethanol and water on the surfaces of the substrates and chips. .

[0047] (2) Print 100μm thick nano-silver solder paste on the substrate and chip connection surfaces cleaned in step (1), place the printed solder paste substrate and chip on a heating table and heat to 120°C for 30 minutes to dry to make the solder paste The low-temperature solvent and adhesive in the medium are fully decomposed and volatilized. After drying, the substrate and chip are removed and cooled to room temperature quickly.

[0048] (3) drop an organic solvent on the...

Embodiment 3

[0051] In this example, the process method for uniform sintering of nano-silver solder paste at low temperature and large area is as follows:

[0052] (1) Set the area to 400mm 2 The chips and metal substrates were ultrasonically cleaned in absolute ethanol for 2 minutes to remove the oily dirt adhering to the surface of the metal substrates, and then dried at 100 °C for 2 minutes using a hot air blower to fully volatilize the absolute ethanol and water on the surfaces of the substrates and chips.

[0053] (2) Print 150 μm thick nano-silver solder paste on the substrate and chip connection surfaces cleaned in step (1), place the printed solder paste substrate and chip on a heating table and heat to 130°C for 40 minutes to dry to make the solder paste The low-temperature solvent and adhesive in the medium are fully decomposed and volatilized. After drying, the substrate and chip are removed and cooled to room temperature quickly.

[0054] (3) drop an organic solvent on the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com