Directional scanning device and method for acquiring real-time position in implant drill needle operation

A scanning device and real-time position technology, applied in dental implants, dental repairs, educational appliances, etc., can solve problems such as unfavorable direct correspondence, deviation of measurement results, and increased risk of infection in the surgical area, so as to achieve convenient use and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

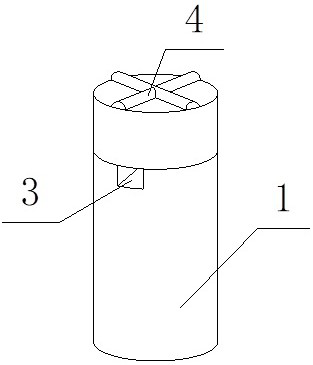

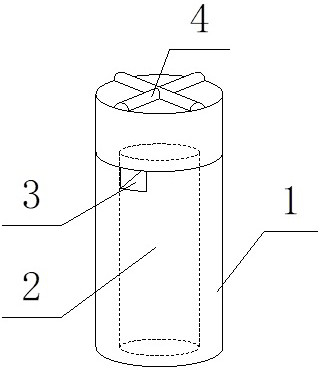

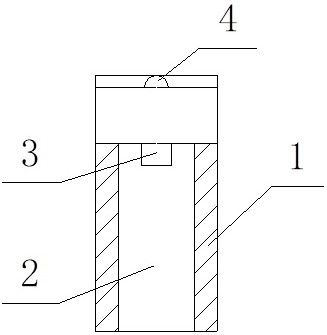

[0036] Such as figure 1 , figure 2 and image 3 As shown, the orientable scanning device provided in this embodiment for obtaining the real-time position of the implant drill includes a sleeve 1, and a vertical blind hole 2 is opened in the center of the bottom of the sleeve 1, and the blind hole 2 is connected with the sleeve. The barrel 1 is set coaxially, and the diameter of the blind hole 2 matches the drill pin, that is, after the drill pin is inserted into the blind hole 2, the drill pin and the blind hole 2 are in clearance fit, and the top side of the blind hole 2 has a penetrating sleeve 1 the visible window 3 on the side wall, the top of the sleeve 1 is provided with a pointing structure 4 composed of two cross-shaped pointers, the center line of the pointing structure 4 coincides with the axis of the sleeve 1, and the pointing structure One of the pointers of 4 is aligned with visible window 3.

[0037] This embodiment also provides a scanning method using the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com