Double-speed double-shaft-shoulder internal material supplementing type friction stir welding device

A friction stir welding, double shoulder technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of increasing the scope of application, the thickness of friction stir welding and the complexity of the welded structure, prone to voids, tunnels, Toe heel, crack and other problems, to improve the welding quality, wide range of welding structure, reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

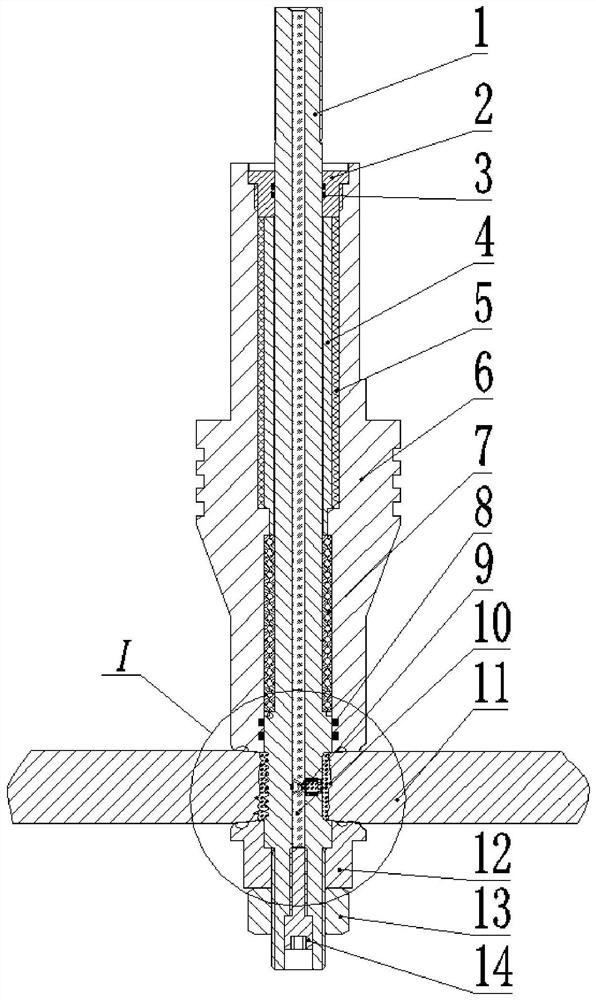

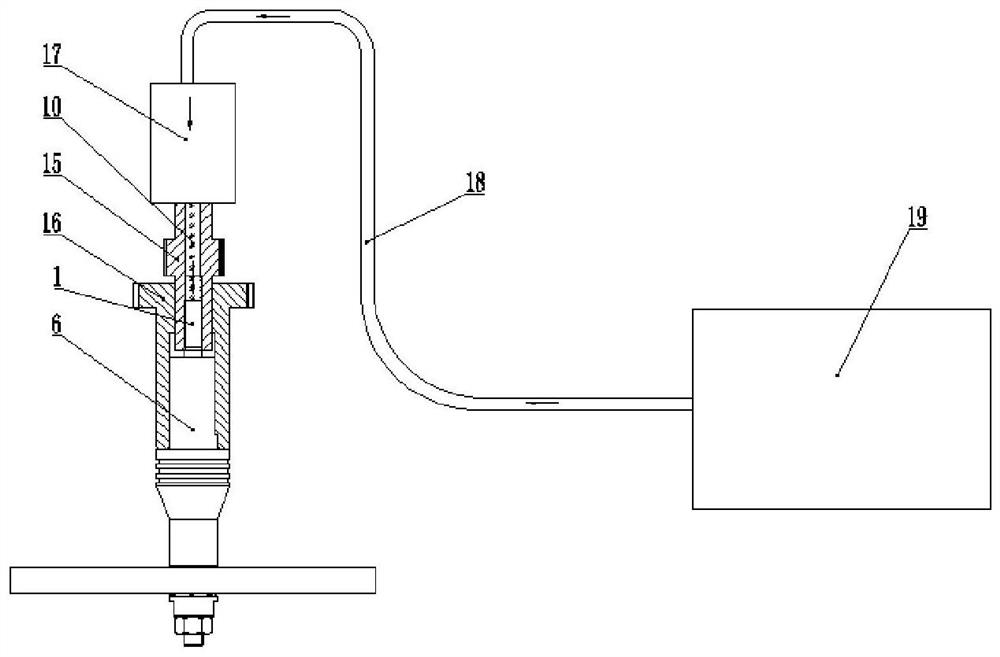

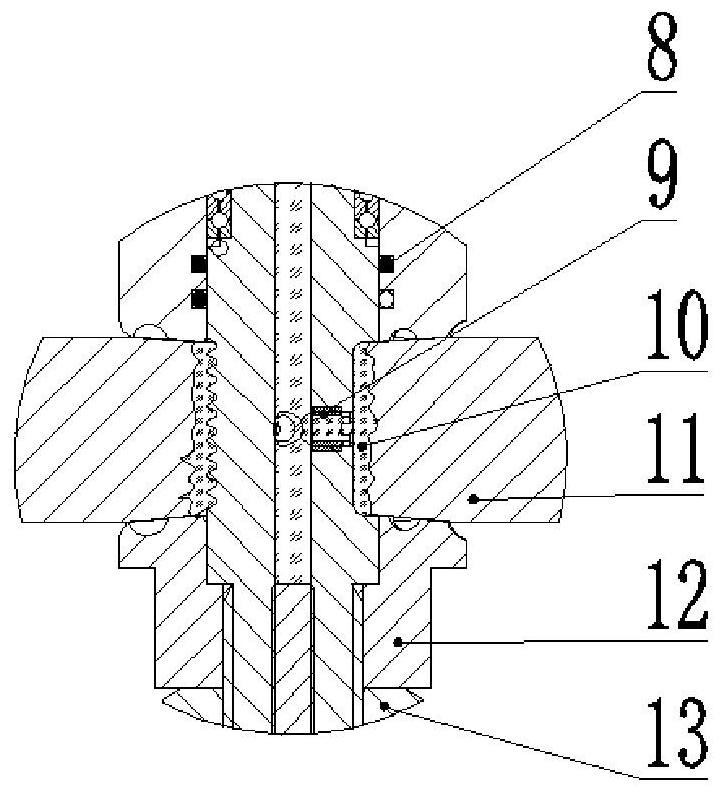

[0022] Example: see attached Figure 1-6 , a double-speed double-shaft internal feeding friction stir welding device, including two parts of a double-speed double-shaft shoulder mechanism and a feeding system, the double-speed double-shaft shoulder mechanism includes a stirring pin 1, a sealing head 2, and a sealing ring a3, shaft sleeve 4, heat insulation sleeve 5, upper shaft shoulder 6, string bearing 7, seal ring b8 nozzle 9, lower shaft shoulder 12, lock nut 13, plug 14, stirring needle 1 is installed on the upper shaft shoulder 6 Between it and the lower shoulder 12, the stirring needle 1 is installed inside the upper shoulder 6 through the string bearing 7, and the sealing ring b8 is used to seal the stirring needle 1 and the upper shoulder 6 to prevent the material from entering the string bearing 7 during the welding process. area, between the stirring pin 1 and the upper part of the upper shaft shoulder 6, install the shaft sleeve 4 and the heat insulation sleeve 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com