Three-point achromatic telecentric scanning laser processing objective lens

A scanning laser and achromatic technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of affecting the accuracy and accuracy of processed workpieces, affecting the accuracy of laser processing, increasing the difficulty of marking real-time positioning and monitoring, etc. problem, achieve the effect of eliminating the interference of chromatic aberration and ensuring accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

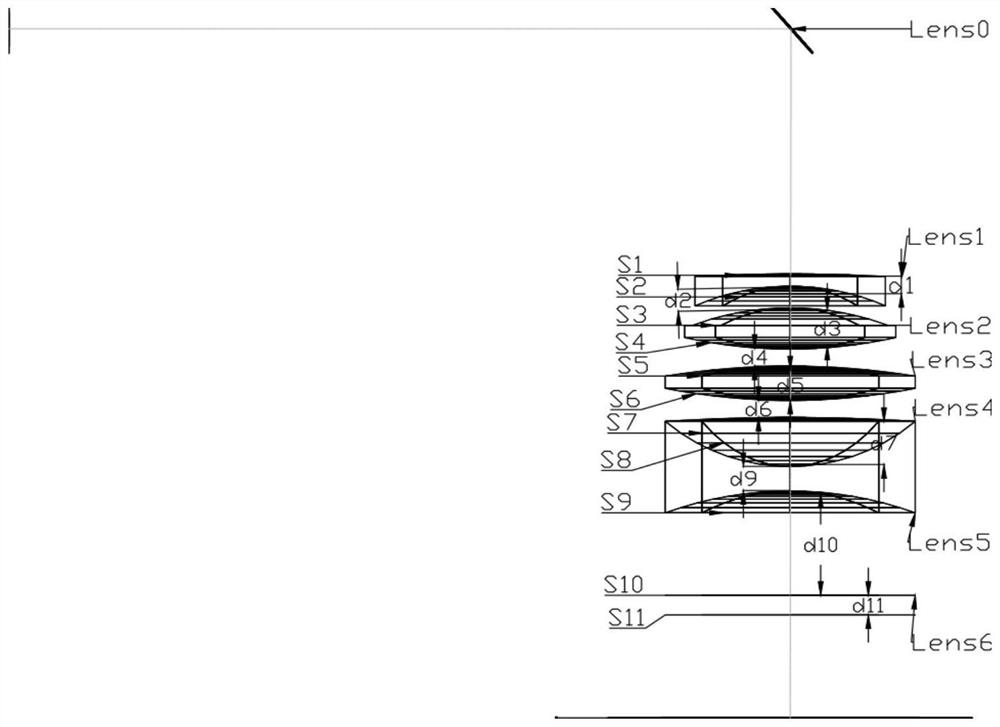

[0029] Such as figure 1 Shown is the structure schematic diagram of laser objective lens of the present invention, and the present invention mainly is made of five lenses, and described five lenses are arranged in order according to the incident direction of laser light as first lens L1, second lens L2, third lens L3, fourth lens Lens L4, fifth lens L5, the first lens L1 is a meniscus lens, and the curved surface faces the direction where the light is emitted; the second lens L2 is a biconvex lens; the third lens L3 is a biconvex lens, and the fourth lens L4 is A biconvex lens, the fifth lens L5 is a biconcave lens. When the above lens groups constitute the actual optical system, in order to protect the exposed lens or any other purpose, an optical window composed of parallel flat plates is added on the outgoing direction of the lens groups. The present invention adds a flat mirror L6 in front of the lens L5.

[0030] Their specific structures and parameters are: the first le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com