Motor automatic winding equipment capable of self-checking cable

An automatic winding and cable technology, applied to motor vehicles, cleaning methods using tools, trolleys, etc., can solve problems such as uneven winding and reduced performance of winding length, so as to avoid loose winding, improve precision, Avoid the effect of secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

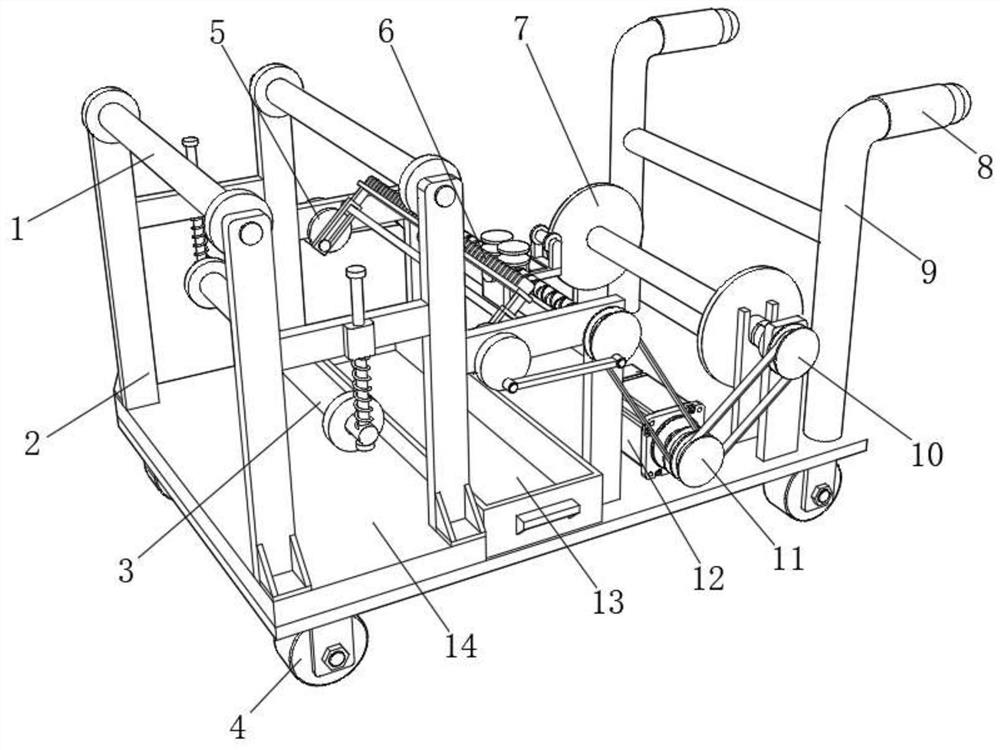

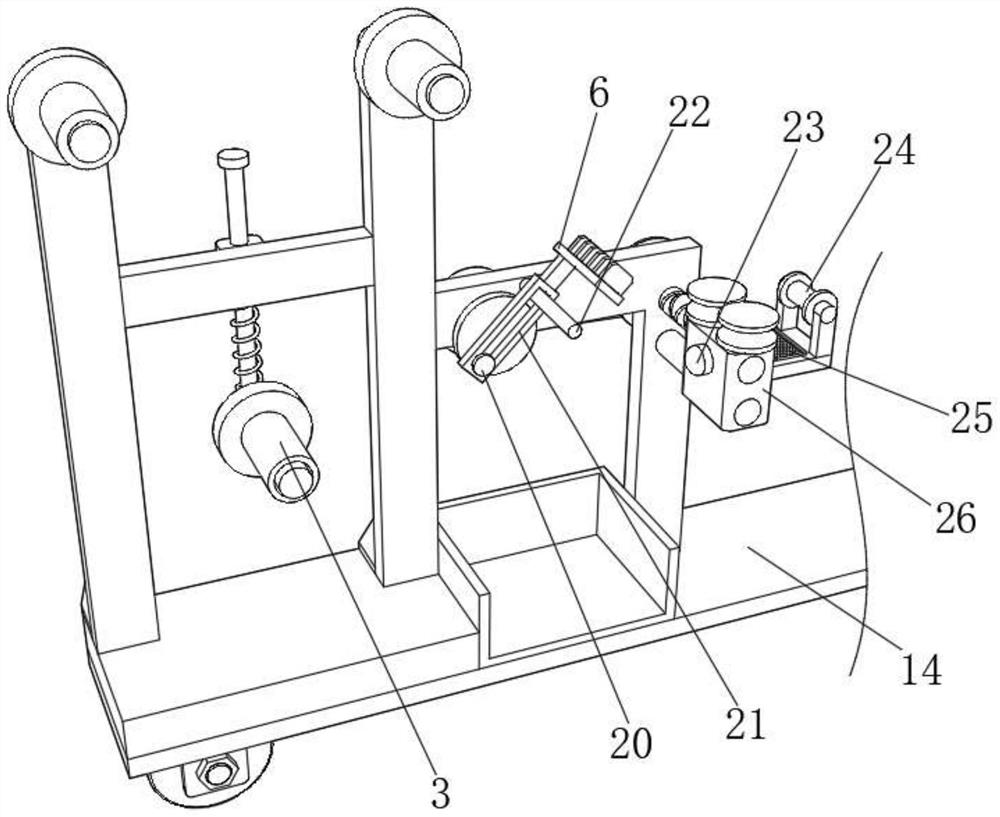

[0032] refer to Figure 1-Figure 5 , an automatic motor winding device capable of self-inspection of cables and cables, including a base plate 14, the upper surface of the base plate 14 is fixed with a motor 12 by bolts, and one end of the output shaft of the motor 12 is key-connected with a double-groove pulley 11, the base plate 14 Two support plates 30 are fixed on the upper surface of the support plate 30 by bolts, a groove is provided on the top of the support plate 30, and a winding reel 7 is rotatably connected in the groove, and the two ends of the rewinding reel 7 are fixed with blocks 32 by bolts. The upper surface of the bottom plate 14 is fixed with a first connecting plate 33 by bolts, and one side of the first connecting plate 33 is rotatably connected with a first transmission shaft 31, and one end of the first transmission shaft 31 is provided with a first card slot, and the first card The groove is clamped with the block 32, and the other end key of the first ...

Embodiment 2

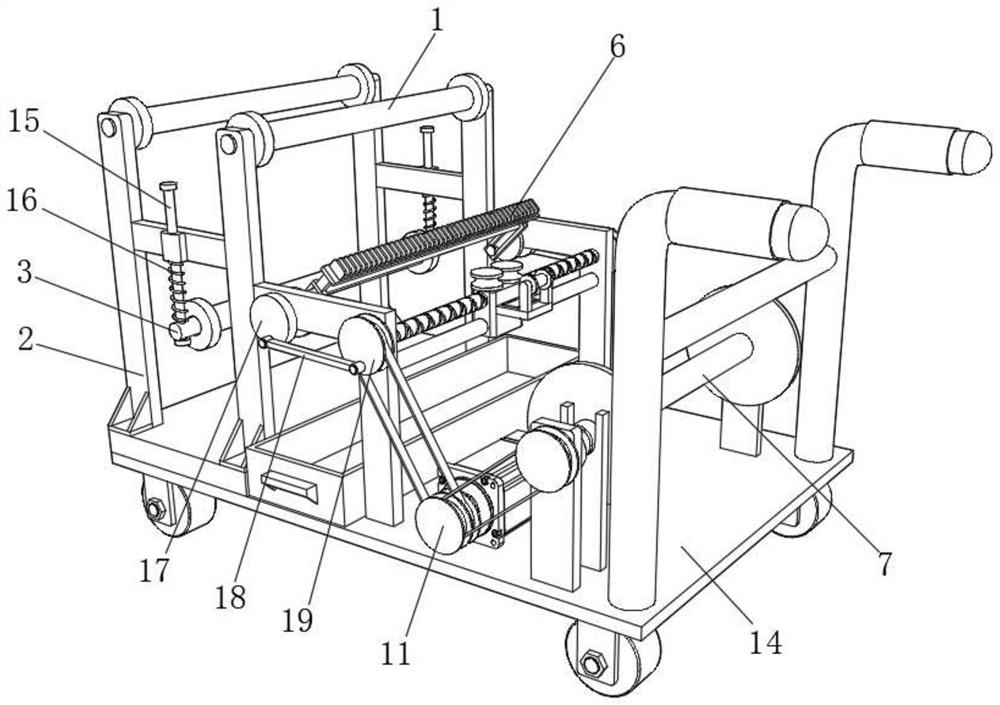

[0036] refer to Figure 6-Figure 7 , a kind of electric motor automatic winding equipment that can carry out self-inspection for cables and cables, also includes a second connecting plate 34, one side of the second connecting plate 34 is rotatably connected with a second transmission shaft 39, and one end of the second transmission shaft 39 is opened There is a second card slot, and the second card slot is engaged with the block 32, the other end of the second transmission shaft 39 is keyed to a ratchet 35, and one side of the second connecting plate 34 is rotatably connected to a ratchet 36, and the ratchet Claw 36 is clamped with ratchet 35, and one side of second connecting plate 34 is fixed with fixed column 38 by bolt, and one end of fixed column 38 is fixed with second spring 37 by bolt, and the other end of second spring 37 and ratchet 36 is fixed by bolts, and the ratchet 36 can prevent the reverse setting of the ratchet 35, so that when the reel 7 stops rewinding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com