A temperature-sensitive adhesive bridging plugging system, plugging slurry and its preparation method and application

A temperature-sensitive adhesion type, bridging plugging technology, applied in chemical instruments and methods, instruments, computer materials science, etc., can solve the problems of low plugging success rate, poor adhesion of crack wall, damage, etc., to achieve enhanced Plugging strength and stability, stable melting temperature, and the effect of overcoming low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

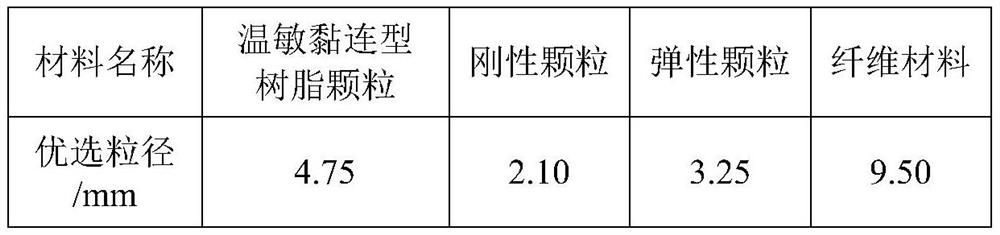

[0071] A temperature-sensitive adhesive bridging plugging system, comprising the following raw materials in mass percentage: 40% of temperature-sensitive adhesive resin particles, 25% of rigid particle materials, 25% of elastic particle materials, and 10% of fiber materials;

[0072] Wherein, the rigid particle material is walnut shell particles; the elastic particle material is rubber particles; the fiber material is polyamide fiber;

[0073] The temperature-sensitive adhesive resin particles are prepared according to the following method:

[0074] (1) Preparation of modified solid-phase filled melting range modifiers

[0075] Add 25g of oven-dried silicon dioxide (90nm particle size) into 500mL of dichloromethane, and ultrasonically disperse for 30min to obtain a suspension a; add 20mL of vinyltrimethoxysilane dropwise to the suspension a for a time of 30 minutes, ultrasonic dispersion for 10 minutes to obtain a suspension b, then stand at 70°C for 8 hours, centrifuge, and ...

Embodiment 2

[0088] A temperature-sensitive adhesive bridging plugging system, comprising the following raw materials in mass percentage: 40% of temperature-sensitive adhesive resin particles, 25% of rigid particle materials, 25% of elastic particle materials, and 10% of fiber materials;

[0089] Wherein, the rigid particle material is walnut shell particles; the elastic particle material is rubber particles; the fiber material is polyamide fiber;

[0090] The preparation method of the temperature-sensitive adhesive resin particles is as follows:

[0091] (1) Preparation of modified solid-phase filled melting range regulator:

[0092] Add 25g of dried zeolite powder (with a particle size of 10μm) into 500mL of dichloromethane, and ultrasonically disperse for 30min to obtain suspension a; add 20mL of vinyltrimethoxysilane dropwise to suspension a for 30min , ultrasonically dispersed for 10 minutes to obtain a suspension b, then left to react at 70°C for 8 hours, centrifuged, and vacuum-dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com