Light and thin anti-perspective down-proof cloth and preparation method thereof

A technology of anti-perspective and anti-feather cloth is applied in the field of textile weaving, which can solve the problems of decreased air permeability and comfort, unfavorable use by hotel users, and high cost of double-layer anti-velvet fabrics, so as to improve air permeability and comfort, and improve the anti-fleece fabric. The effect of drilling down ability and anti-color down effect is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

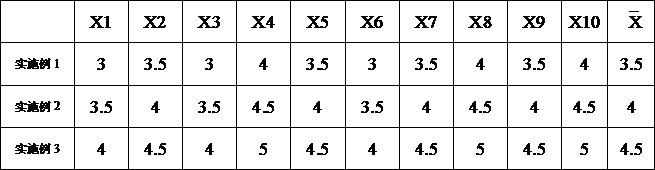

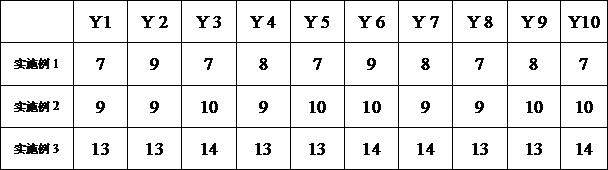

Embodiment 1

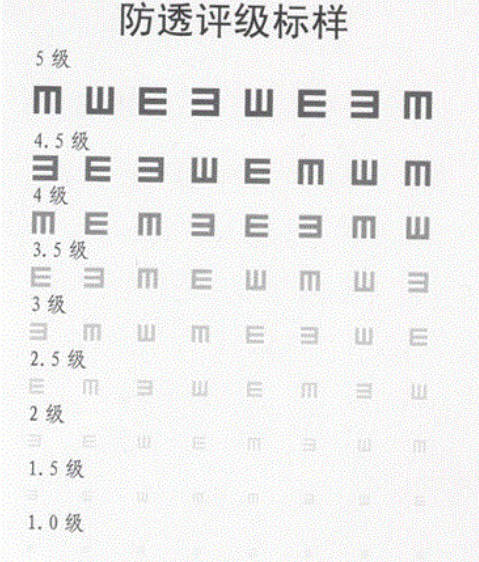

[0028] S1: Anti-see-through fabric weaving: the warp is made of anti-see-through polyester DTY filament (65D, the number of multifilaments in the fiber cross-section is 72), the weft is made of 40S anti-see-through polyester-cotton yarn, and the content of anti-see-through polyester is 65%, and it is made with 1 / 1 plain weave High-density weaving on the machine, the weaving tightness is not less than 95%, and the weight is 105 g / m²;

[0029] S2: Preparation of anti-transparency and anti-drilling down finishing solution: In deionized water, add 80g / L anti-transparency finishing agent for fabrics (Shanghai Wangjie Trading Co., Ltd. Kamaset DP-40 anti-transparency finishing agent for fabrics), 25g / L L crosslinking agent (Shanghai Wangjie Trading Co., Ltd. Kamaset AC-55 crosslinking agent), 15g / L non-ionic windproof agent, adjust the finishing liquid pH=6.0, stir evenly, obtain anti-transparency and anti-drilling velvet composite finishing liquid.

[0030] S3: padding, drying, and...

Embodiment 2

[0033] S1: anti-see-through fabric weaving: the warp is made of anti-see-through polyester DTY filament (75D, the number of multifilaments in the fiber cross-section is 72), the weft is made of 40S anti-see-through polyester-cotton yarn, the anti-see-through polyester content is 70%, and it is made of 1 / 1 plain weave High-density weaving on the machine, the weaving tightness is not less than 95%, and the weight is 110 g / m²;

[0034] S2: Preparation of anti-transparency and anti-drilling down finishing solution: In deionized water, add 80g / L anti-transparency finishing agent for fabrics (Shanghai Wangjie Trading Co., Ltd. Kamaset DP-40 anti-transparency finishing agent for fabrics), 25g / L L crosslinking agent (Shanghai Wangjie Trading Co., Ltd. Kamaset AC-55 crosslinking agent), 15g / L non-ionic windproof agent, adjust the finishing liquid pH=6.0, stir evenly, obtain anti-transparency and anti-drilling velvet composite finishing liquid.

[0035] S3: padding, drying, and finalizi...

Embodiment 3

[0038] S1: Anti-see-through fabric weaving: the warp is made of anti-see-through polyester DTY filament (100D, the number of multifilaments in the fiber cross-section is 72), the weft is made of 40S anti-see-through polyester-cotton yarn, and the content of anti-see-through polyester is 75%, and it is made of 1 / 1 plain weave High-density weaving on the machine, the weaving tightness is not less than 95%, and the weight is 120 g / m²;

[0039] S2: Preparation of anti-transparency and anti-drilling down finishing solution: In deionized water, add 80g / L anti-transparency finishing agent for fabrics (Shanghai Wangjie Trading Co., Ltd. Kamaset DP-40 anti-transparency finishing agent for fabrics), 25g / L L crosslinking agent (Shanghai Wangjie Trading Co., Ltd. Kamaset AC-55 crosslinking agent), 15g / L non-ionic windproof agent, adjust the finishing liquid pH=6.0, stir evenly, obtain anti-transparency and anti-drilling velvet composite finishing liquid.

[0040]S3: padding, drying, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com