Environment-friendly composite combustion boiler

An environmentally friendly, boiler technology, applied in the field of combustion boilers, can solve the problems of affecting the natural ecological environment, waste of material resources, complicated operation, etc., and achieve the effects of convenient cleaning, increased life, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

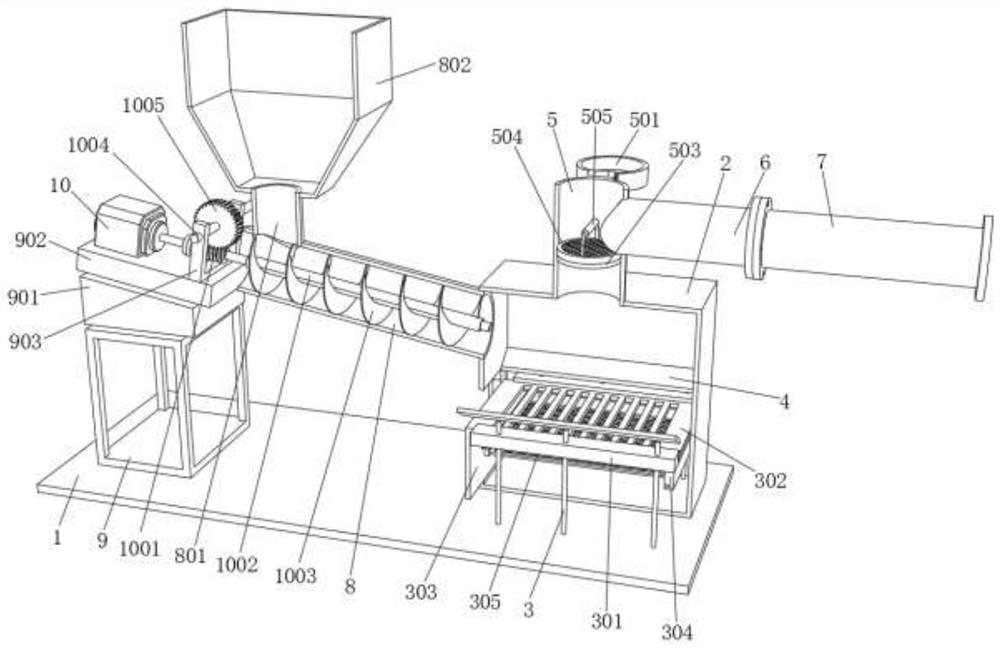

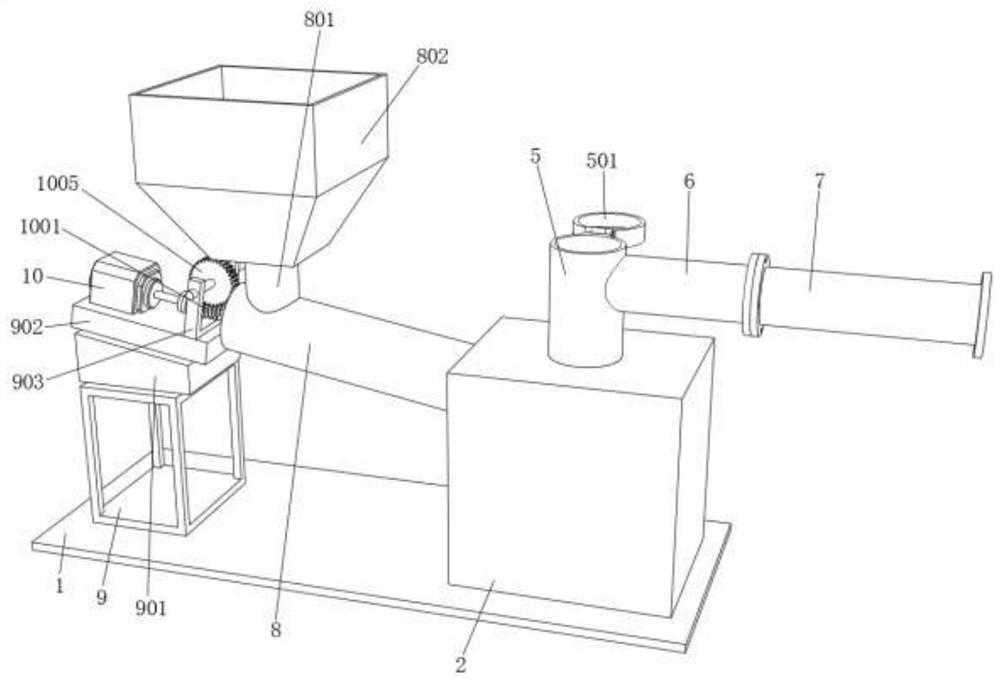

[0035] refer to Figure 1-Figure 4, an environment-friendly composite combustion boiler, including a bottom plate 1, a furnace body 2 is fixed on the upper surface of the bottom plate 1 by bolts, a sealing port is provided on one side of the outer wall of the furnace body 2, and a sealing door 201 is rotatably connected to the side of the sealing port, and the furnace body 2 The bottom of the inner wall is welded with a plurality of guide rods 3, and every three guide rods 3 are slidably connected to the same slide rail 301, there are two slide rails 301, and the two slide rails 301 are slidably connected to the same hollow plate 302, and one end of the hollow plate 302 A connecting plate 303 is integrally formed, and one side of the connecting plate 303 is provided with a plurality of placement openings, and the plurality of placement openings are formed with two installation strips, and the bottom of the two slide rails 301 is fixed with the same connecting strip 304 by bolts...

Embodiment 2

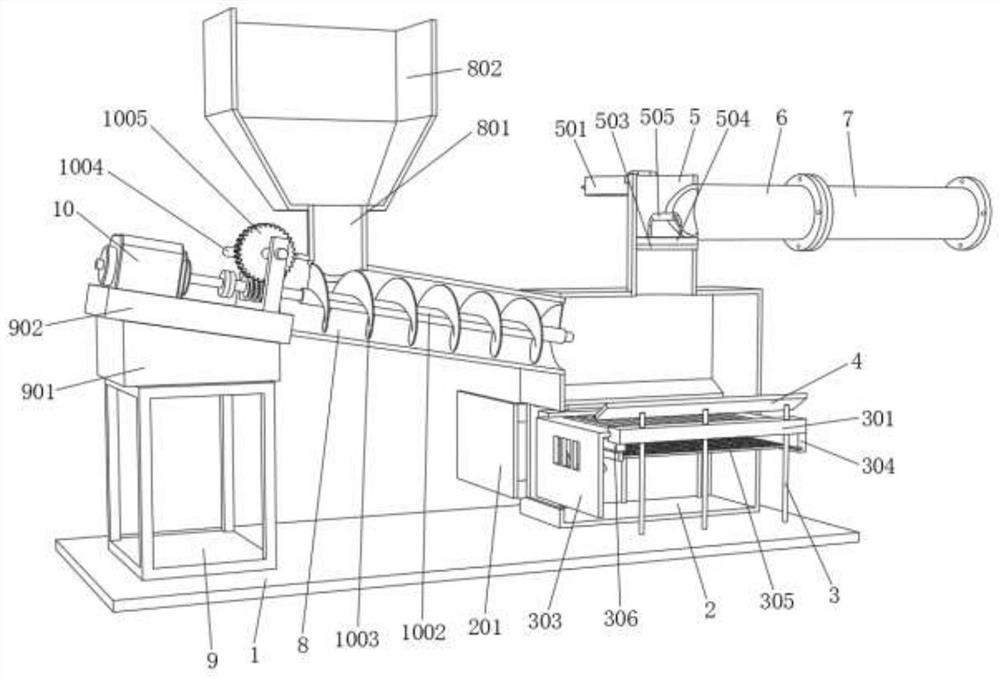

[0039] refer to Figure 5-Figure 7 , Both sides of the inner wall of the furnace body 2 are provided with movable holes, and the same rotating rod 11 is plugged into the two movable ports, and the circumference of the rotating rod 11 is keyed with a cam 1101, and the cam 1101 is located between the hollow plate 302 and the filter screen 305 , the rotating assembly is formed by the cooperation of the rotating rod 11 and the cam 1101. When the rotating rod 11 drives the cam 1101 to rotate, it simultaneously drives the guide rod 3 and the protective components on it to vibrate, so as to avoid the accumulation of fly ash on the hollowed out plate 302 and speed up the hollowing out process. The fall of the fly ash on the plate 302 ensures that the fuel combustion on the hollow plate 302 has sufficient stability, and the ends of the rotating rod 11 and the rotating shaft 1004 are all keyed to a heat-insulating ring, and one side of the circumference of the two heat-insulating rings i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com