Membrane mechanical strength characterization method and device based on membrane pressure test

A technology of mechanical strength and thin film, which is applied in the field of mechanical strength detection of thin film, can solve the problems that the mechanical strength of thin film cannot be tested effectively, and achieve the effect of reliable and stable test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

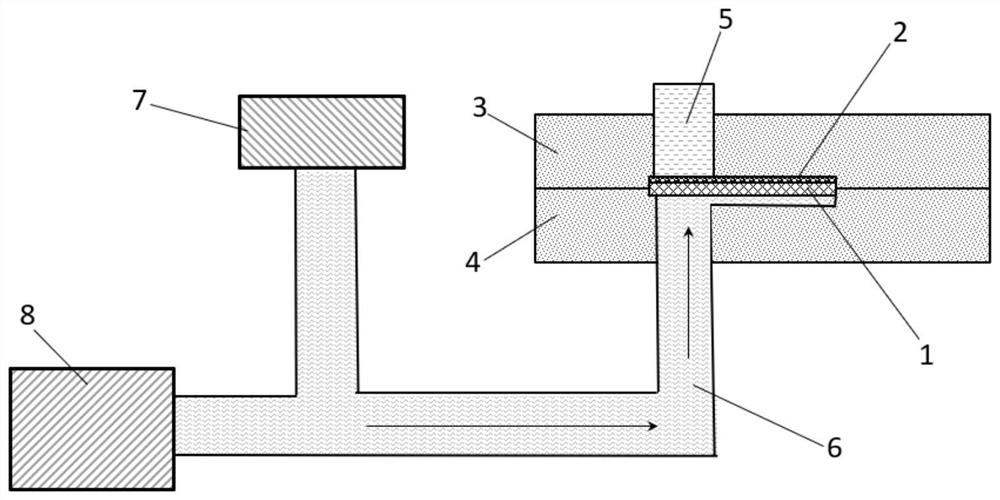

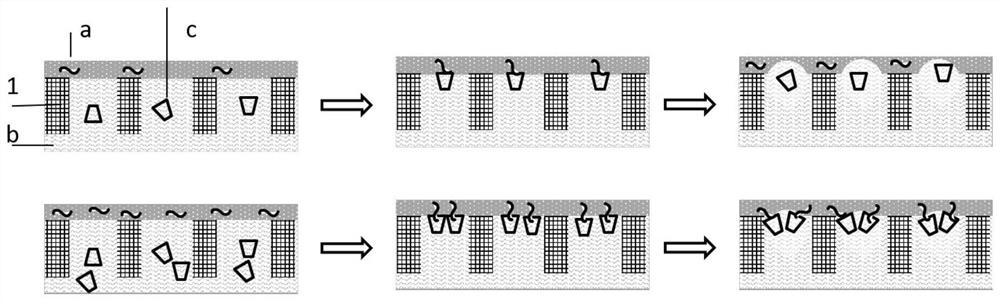

[0034] This embodiment provides a method for detecting the mechanical strength of a thin film placed on a porous membrane through a membrane pressure testing device. The film has the characteristics of low mechanical strength and it is difficult to effectively test and characterize its mechanical strength. refer to figure 1 , with porous material (for example porous film) as carrier 1, described carrier 1 has relative upper surface and lower surface; placed in a closed channel. Specifically, the carrier 1 carrying the film to be tested 2 can be placed between the upper fixture 3 and the lower fixture 4 to seal, the upper cavity 5 communicates with the film to be tested 2 through the upper fixture 3, and the lower channel 6 communicates with the carrier 1 through the lower fixture 4 The upper cavity 5 and the lower channel 6 are connected by the upper clamp 3 and the lower clamp 4 to form the aforementioned airtight channel whose conduction is determined by the carrier 1 and ...

Embodiment 2

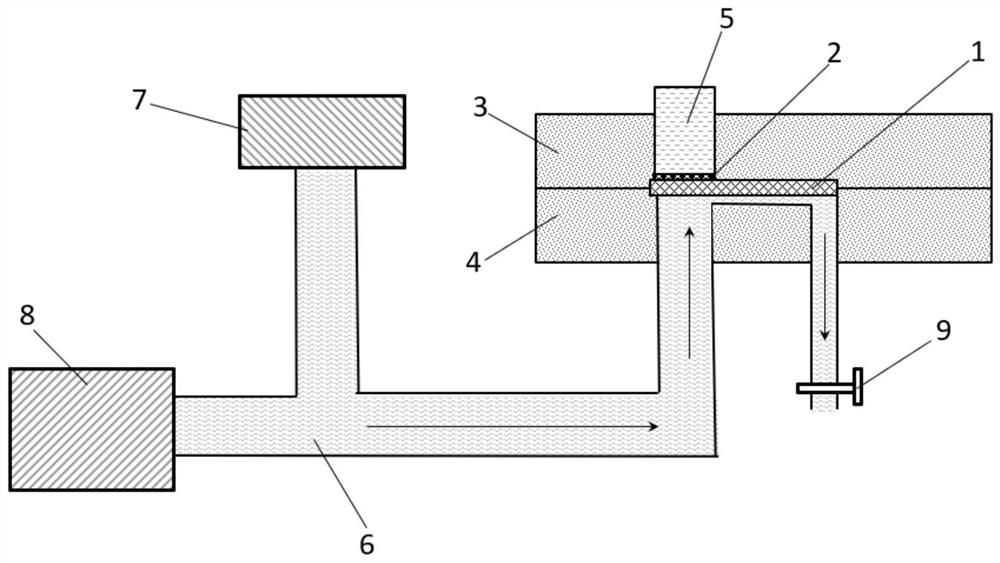

[0036] refer to figure 2, a thin film mechanical strength characterization device based on the membrane pressure test, comprising a first phase cavity 5, a second phase channel 6, a carrier porous membrane 1 and a syringe pump or a peristaltic pump 8; the first phase cavity 5 and the second phase The phase channel 6 is sealed and connected up and down to form a closed channel, and the porous membrane 1 is arranged at the junction of the first phase cavity 5 and the second phase channel 6 and separates the closed channel. Specifically, the porous membrane 1 can be sealed between the upper clamp 3 and the lower clamp 4, the first phase cavity 5 communicates with the upper surface of the porous membrane 1 through the upper clamp 3, and the second phase channel 6 communicates with the porous membrane 1 through the lower clamp 4. The lower surface of the membrane 1 communicates, and the pressure sensor is connected to the second phase channel 6 . The first phase cavity 5 is used ...

Embodiment 3

[0045] This embodiment utilizes the host-guest interaction between cyclodextrin and alkane, in figure 2 Films were grown in the setup shown and their mechanical strength was examined. The aqueous solution system in this embodiment can be α-cyclodextrin, β-cyclodextrin or γ-cyclodextrin, and the oil phase system can be dodecane, tetradecane or hexadecane, etc. The concentration of cyclodextrin can be 0.001 mol / L to 0.005 mol / L. The alkane is poured into the cavity 5 of the first phase, and the alkane contacts and diffuses with the upper surface of the porous membrane 1 . The aqueous solution of cyclodextrin is injected into the entire second phase channel 6 . In the second phase channel 6 , the cyclodextrin aqueous solution in the second phase channel 6 has a certain flow through the peristaltic pump, and the dextrin aqueous solution contacts and diffuses with the lower surface of the porous membrane 1 . The porous membrane 1 of this embodiment is made of hydrophilic, such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com