Brake material friction coefficient evaluation method

A friction coefficient and brake material technology, which is used in the field of aircraft brake material performance testing to reduce economic losses, shorten the cycle of repeated tests, and improve the development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] This embodiment is used to obtain the braking speed V of the braking material transient friction coefficient (t) , specific pressure P (t) and temperature T (t) The relationship between the three; thus the simulation analysis of the temperature field and brake vibration of a certain type of aircraft.

[0059] The concrete process of this embodiment is:

[0060] Step 1: Prepare a friction sample to obtain the average coefficient of friction:

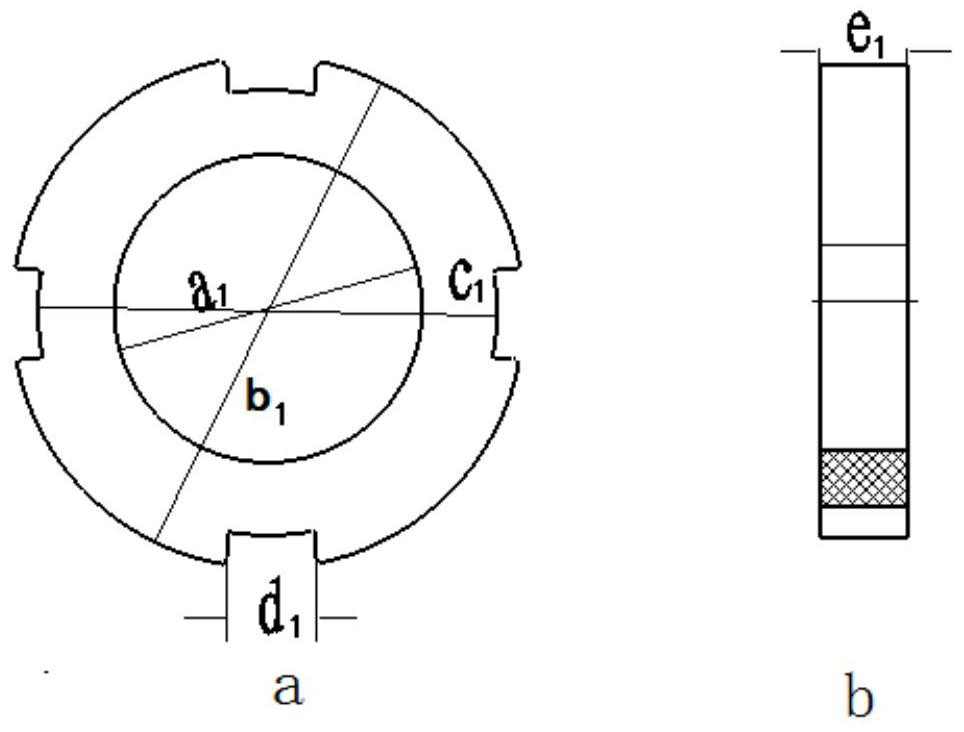

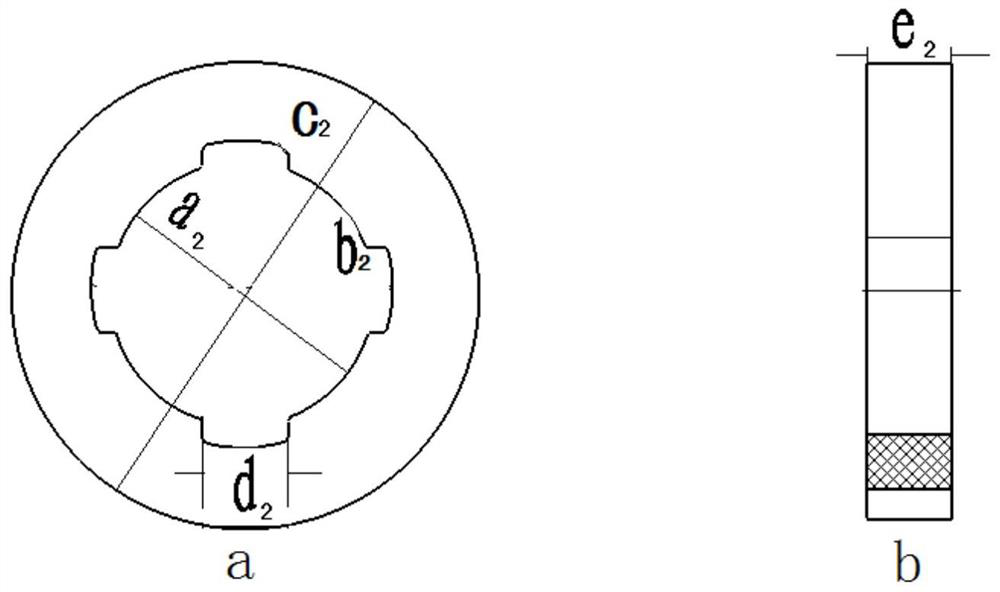

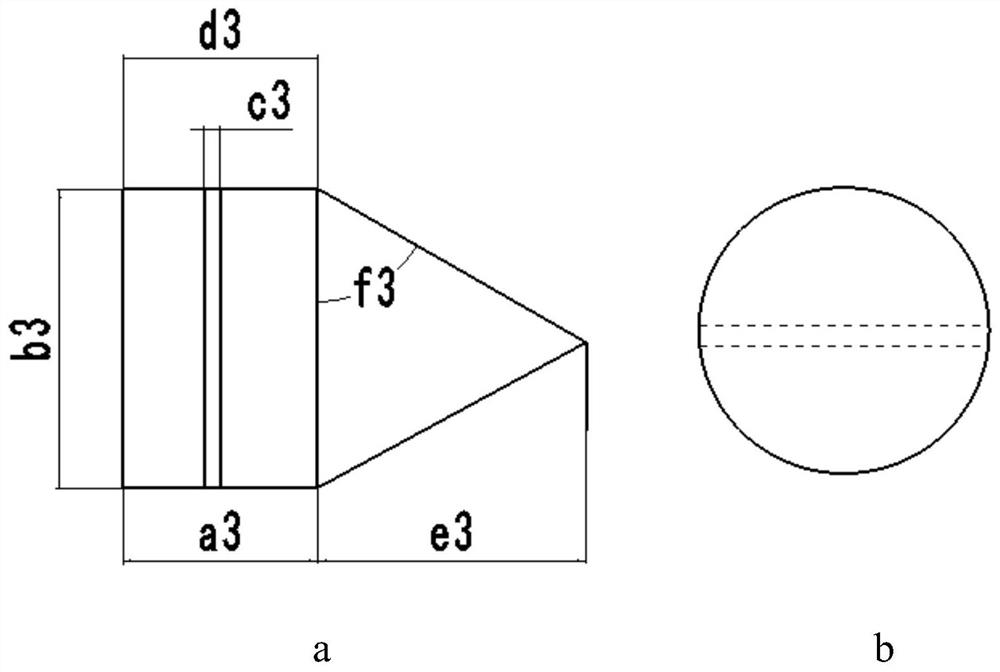

[0061] The friction samples include static friction samples and dynamic friction samples. The shape and structure of the static friction sample is the same as that of the static disc in the brake disc. The shape and structure of the dynamic friction sample is the same as that of the moving disc in the brake disc.

[0062] The friction contact mode between the static friction sample and the dynamic friction sample is surface contact.

[0063] In this embodiment, the inner diameter a of the dynamic friction sample of the averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com