Intelligent optical fiber junction box

An intelligent optical fiber and junction box technology, which is applied to optics, light guides, optical components, etc., can solve the problems of inconvenient optical fiber coiling and fixing, and achieve the effects of reducing transmission loss, simplifying coiling operations, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

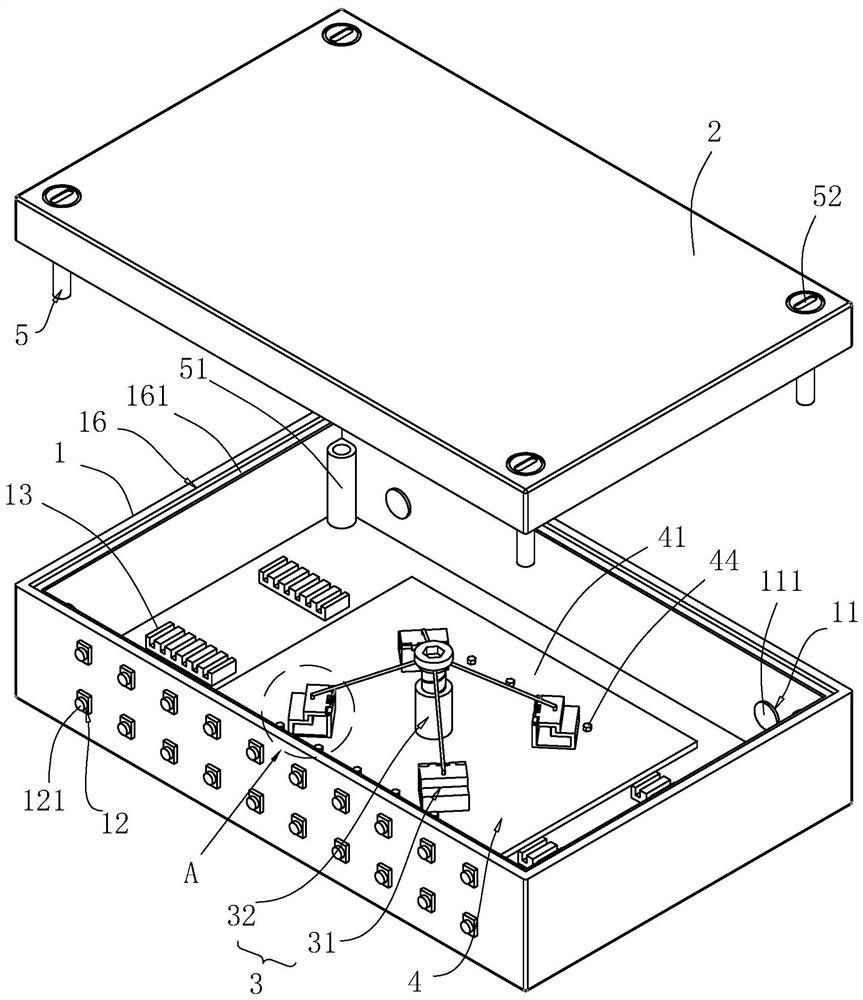

[0041] refer to figure 1 , The intelligent optical fiber junction box includes a box body 1 , a box cover 2 , a winding mechanism 3 , a cooling mechanism 4 and a fixing mechanism 5 . The cooling mechanism 4 and the winding mechanism 3 are arranged on the box body 1, the box cover 2 is set on the box body 1 through the fixing mechanism 5, and two wire inlet holes 11 are provided on the side wall of the box body 1, and the wire inlet holes 11 The middle plug is provided with a plug 111, and a plurality of outlet holes 12 are opened on the other side wall, and an optical fiber fixing seat 121 is clamped in the outlet hole 12, and the bottom wall of the box body 1 is also bonded for clamping the optical fiber fusion splicing section The card socket 13.

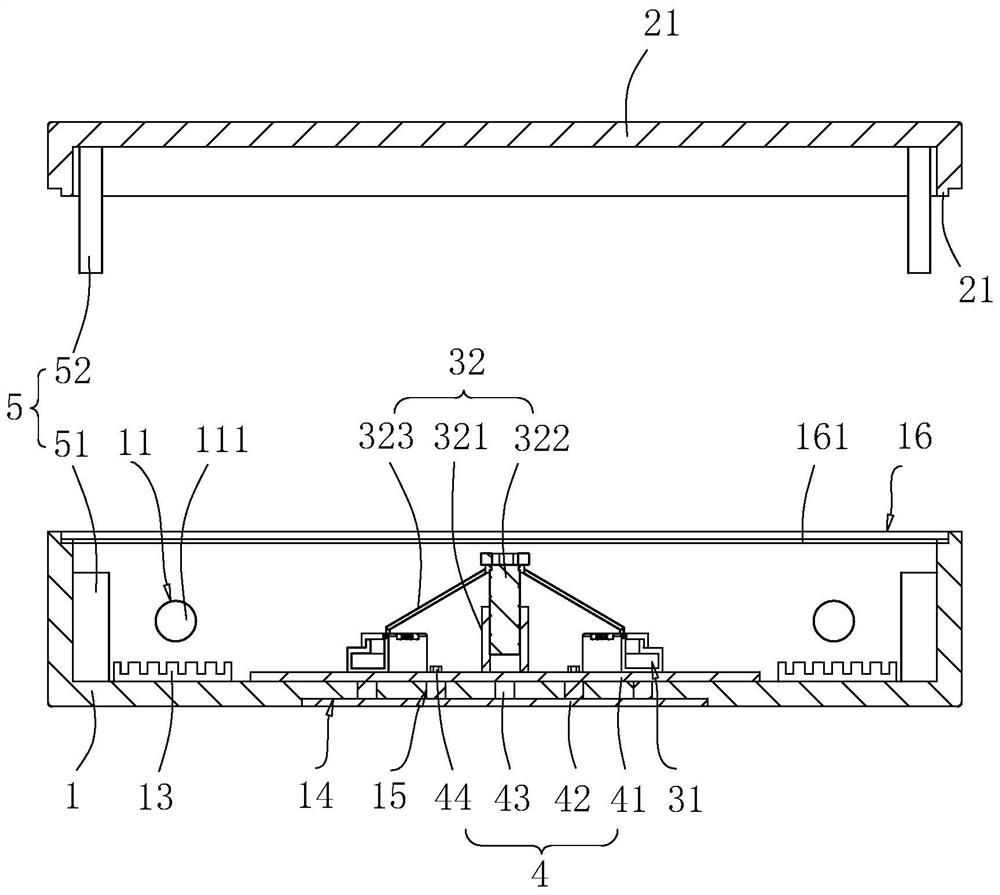

[0042] refer to figure 2 The cooling mechanism 4 includes a first heat conduction plate 41, a second heat conduction plate 42, and a plurality of heat conduction fins 43. In this embodiment, the first heat conduction plate 41, ...

Embodiment 2

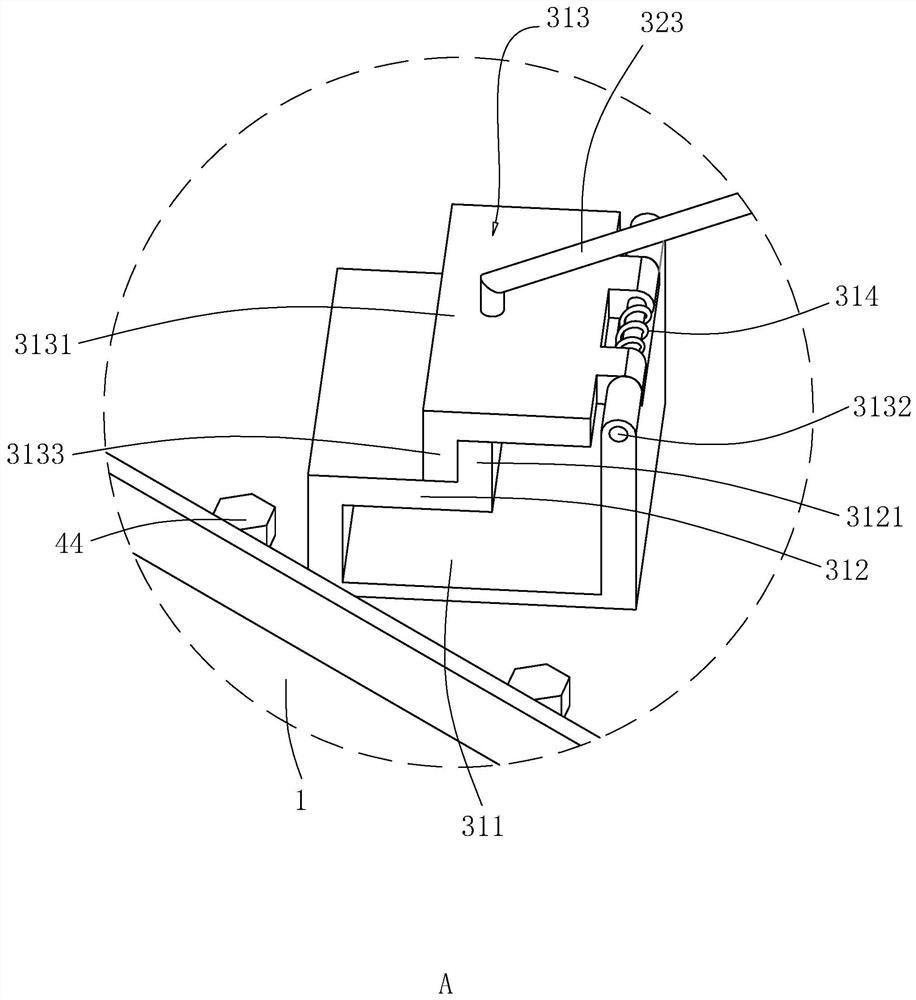

[0049] refer to Figure 5 , the difference between this embodiment and embodiment 1 is: refer to Figure 4 and Figure 5 , the movable part 313 includes a fixed plate 3134, a square bar 3135 and a third clamping vertical plate 3136, the fixed plate 3134 is welded on the top wall of the buckle 311 away from the side of the baffle plate 312, the fixed plate 3134 is higher than the first clamp The connecting riser 3121 is provided, and the height difference between the fixing plate 3134 and the first engaging riser 3121 is also larger than the fiber diameter. In this embodiment, the height difference between the fixing plate 3134 and the first engaging riser 3121 is set to 10mm. The square rod 3135 runs through the fixed plate 3134 in the radial direction along the corresponding point of the circumscribed circle of the clamping assembly 31 and is slidably connected with the fixed plate 3134. The third clamping vertical plate 3136 is welded on the side wall of the square rod 3135...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com