A multi-agent-based early warning method for machining process in NC machining flexible manufacturing system

A flexible manufacturing system and processing process technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as high processing precision, affecting the production and delivery schedule of parts products, and difficult processing, so as to ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

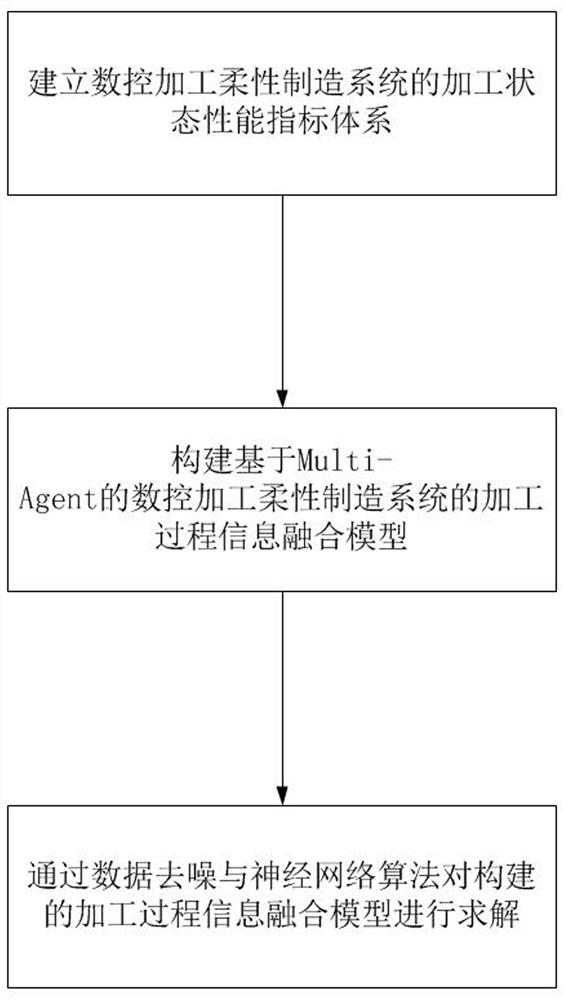

[0040] This embodiment provides a Multi-Agent-based CNC processing flexible manufacturing system processing early warning method, the specific process is as follows figure 1 shown, including the following steps:

[0041] (1) Establish the processing state performance index system of the CNC machining flexible manufacturing system, and evaluate the processing state of the flexible manufacturing system;

[0042] (2) According to the processing state performance index system established in step (1), construct the processing information fusion model of the CNC machining flexible manufacturing system based on Multi-Agent, conduct modeling analysis on the information fusion of the processing process of the flexible manufacturing system, and describe respectively Activities in each stage of data acquisition, data processing, data fusion and process early warning in the process of flexible manufacturing system;

[0043] (3) Starting from data preprocessing, the processing information...

Embodiment 2

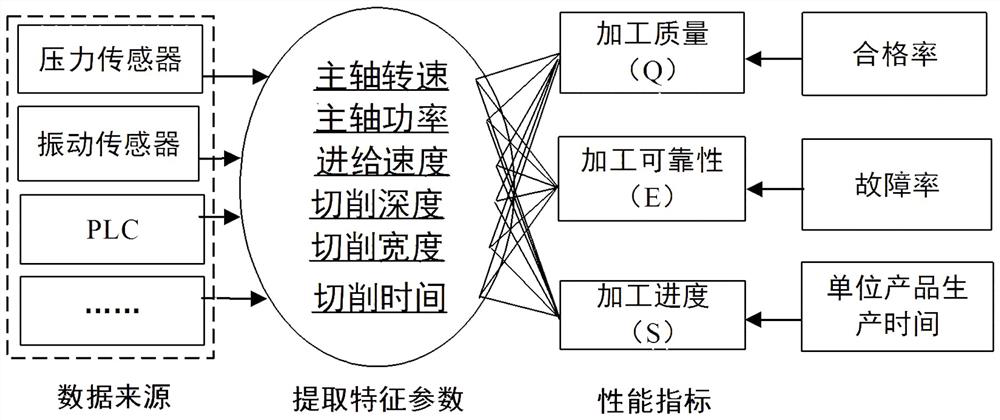

[0045] On the basis of the above-mentioned embodiments, this embodiment further defines the specific composition of the processing state performance index system of the NC machining flexible manufacturing system, such as figure 2 As shown, the established machining state performance index system of the NC machining flexible manufacturing system is mainly composed of a data source layer, a feature parameter layer, and a performance index layer.

[0046] Wherein, the data source layer in the processing state performance index system of the NC machining flexible manufacturing system is the data source of various equipment in the NC machining flexible manufacturing system, and the specific equipment mainly includes PLC, upper computer, pressure sensor, vibration sensor .

[0047] The feature parameter layer is the main parameters reflecting the processing state of the flexible manufacturing system equipment, and the main parameters include spindle speed, spindle power, feed speed...

Embodiment 3

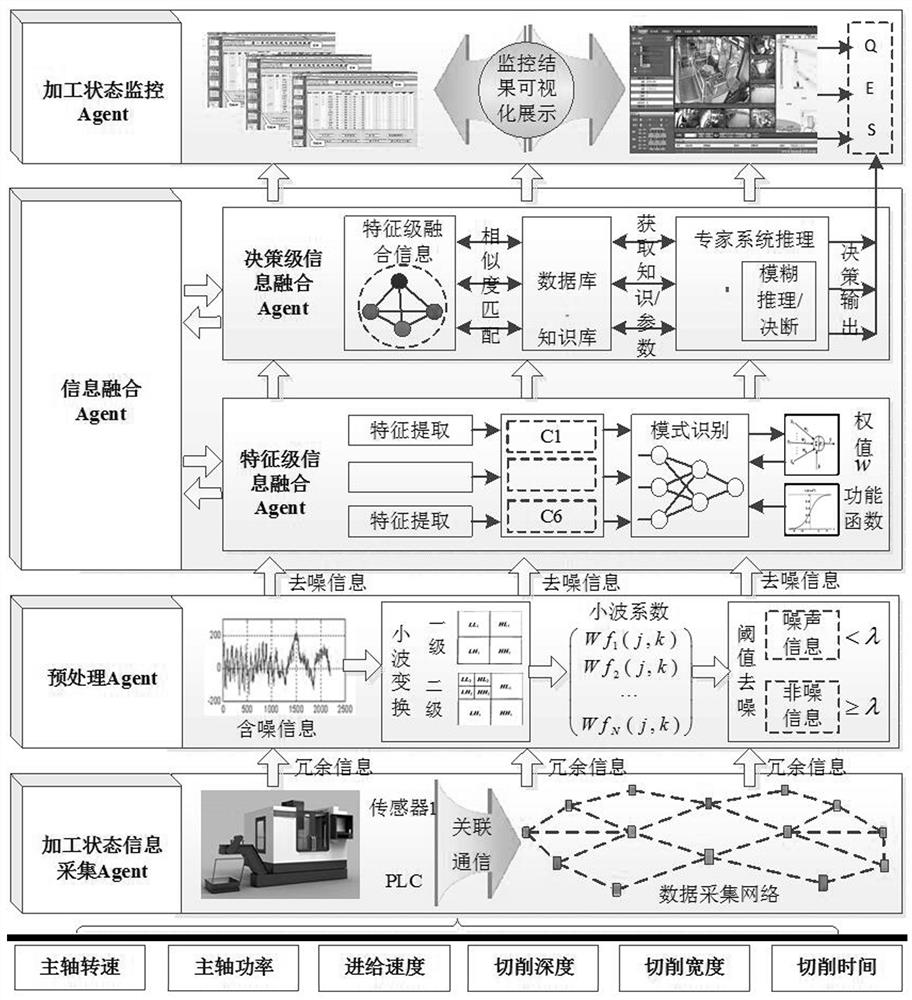

[0050] On the basis of the above-mentioned embodiments, this embodiment further limits the composition of the processing information fusion model of the CNC machining flexible manufacturing system, such as image 3 As shown, the machining process information fusion model of the multi-agent-based NC machining flexible manufacturing system is mainly composed of a four-layer structure of processing state information acquisition agent, information preprocessing agent, information fusion agent, and processing state monitoring and early warning agent .

[0051] Wherein, the processing state information collection Agent is an agent for all processing state information collection under the complex, dynamic and changeable production environment of the CNC machining flexible manufacturing system, which can collect the processing state of the flexible manufacturing system in different orientation environments in real time through the data collection network Information, and the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com