Process for producing semiconductor bodies with MOVPE-layer sequence

A technology of semiconductor and layer sequence, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of low external quantum efficiency, achieve the effect of improving light output coupling and improving light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

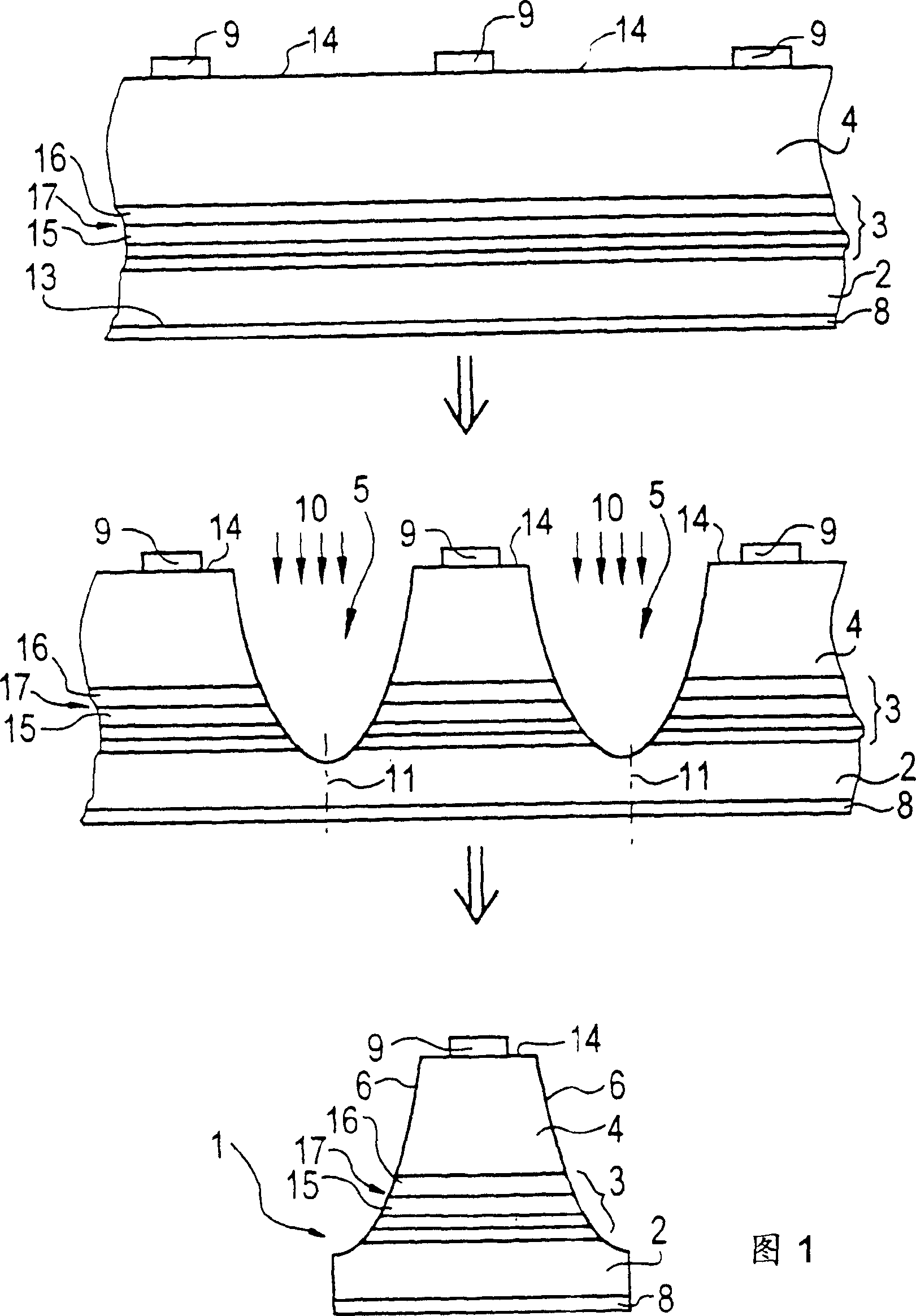

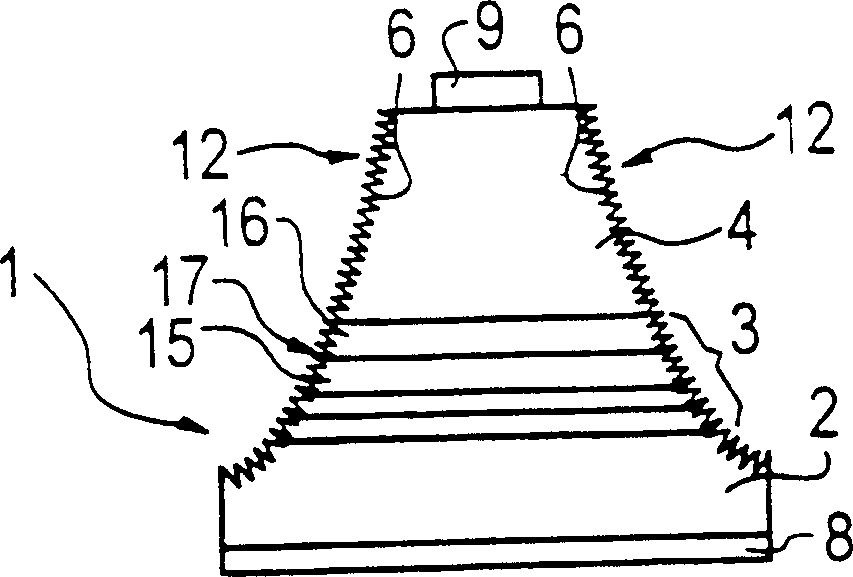

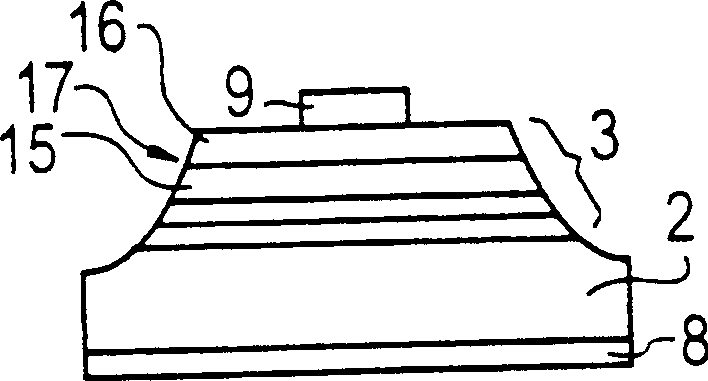

[0038] In these different figures the same components are each provided with the same associated reference numerals.

[0039] In the method according to FIG. 1, a layer sequence 3 is first deposited on a substrate disk 2 made of, for example, gallium arsenide, using metal-organic vapor phase epitaxy (MOVPE). This layer sequence is made of InGaAsP, for example, and has an active region 17 . The active region 17 is, for example, a Pn junction of a light emitting diode. The layer sequence 3 here has, for example, an n-type 15 and a p-type InGaAlP epitaxial layer 16 .

[0040] The active region 17 is constructed such that it emits light if a current is applied to it, and / or generates a voltage if the active region receives light. Such various active regions and the associated various fabrication methods are well known to those skilled in the art and will therefore not be described in detail here.

[0041] A window layer 4 , for example made of GaP or AlGaAs, is then deposited o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com